What’s new in Opcenter X 2507

Opcenter X for scalable digital transformation

Summary

Siemens Digital Industries Software is pioneering modular MOM, enabling more manufacturers to take a stepwise approach to digital transformation. Built with cloud technologies and offered as software as a service (SaaS), using Opcenter™ X software, which is part of the Siemens Xcelerator business platform of software hardware and services, lowers the time and cost barriers for SMBs, enabling you to realize rapid return-on-investment (ROI) with modules that connect and adapt as your enterprise matures.

With Siemens as your MOM solution partner, you can be sure Opcenter X is built on a rich and deep knowledge base and the extensive capabilities of a leading software company. We listen to and learn from our customers, then innovate and capture best practices for every digital task. Then we apply best practices to accelerate time-to-value of our software.

Implementing Opcenter X can boost manufacturing productivity, product quality, time-to-market, and compliance by streamlining operations and decision-making. Siemens supports clients in their digital transformation journey, unlocking the full potential of manufacturing operations.

MES Capabilities

- New material picking feature in Operator Terminal including full-screen material view

- Tracking of Electronic Signature both in Shopfloor and Modeling Audit Trail records

- Possibility to update the MTU name during runtime via API call

- Creation of Work Order Operations without Collect Task requirement now possible

- Improved container validation checks incl. quantity and final material validation

Quality Management

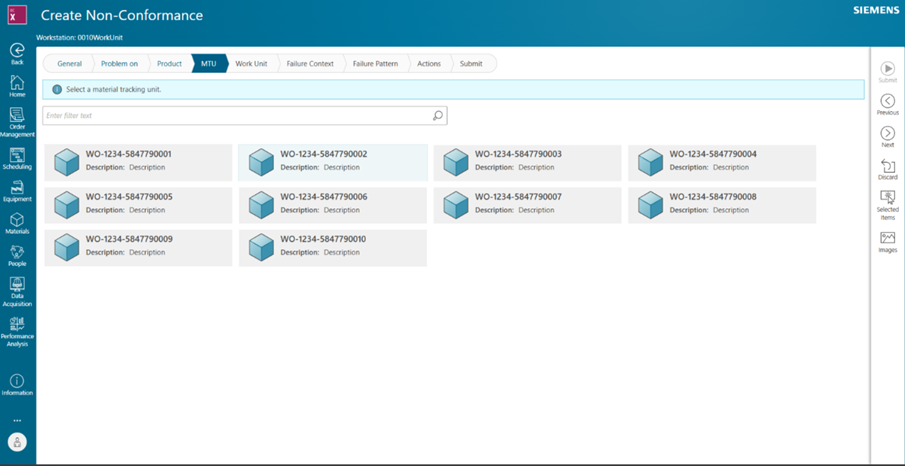

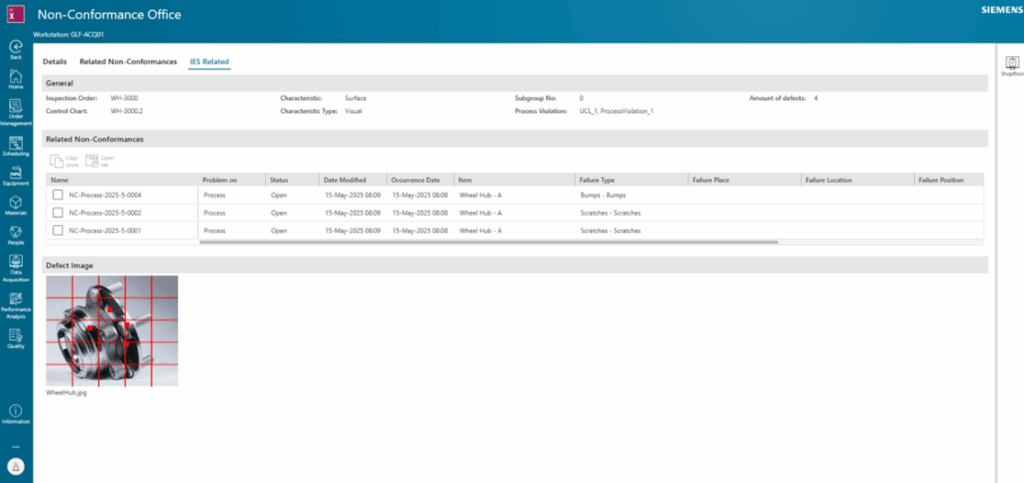

Non-Conformance Management

- New MTU-Failure processing view providing:

- Quick access to affected MTUs from the Overview page

- Comprehensive list of all affected MTUs assigned to NC

- Direct failure pattern editing and action management

- Enhanced NC creation wizard featuring:

- Dedicated MTU selection step

- Visual defect documentation with grid and location support

- Direct editing of Description and Responsible User fields on Office page

- Bulk creation capability for multiple NCs from IES

- Improved submission process showing related failures from IES

Inspection and Control

- Intelligent failure pattern selection system

- Enhanced inspection planning with import capabilities for steps and potential failures

- Improved SPC inspection and evaluation

- Advanced gage management as equipment

- Enhanced update capabilities for next acquisition in Inspection order list

Scheduling

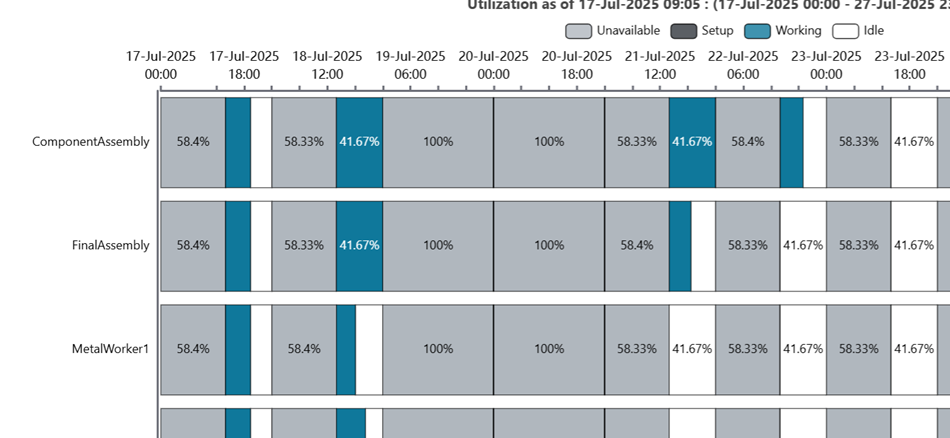

- New Utilization chart providing comprehensive resource utilization visibility across all schedules

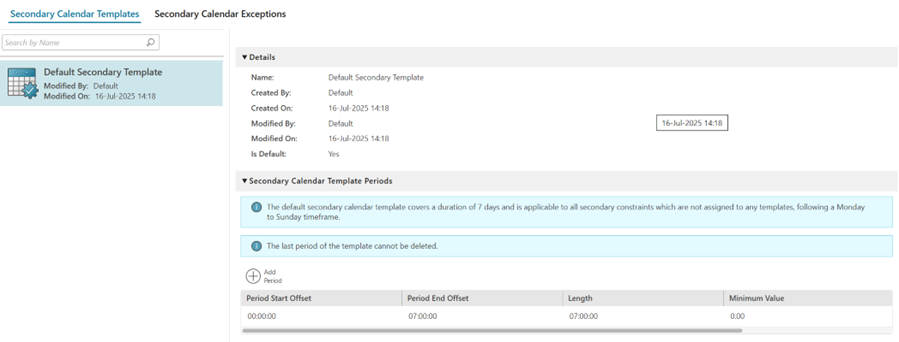

- Enhanced constraint management with:

- New data import functionality to associate constraints with resources

- Introduction of Secondary Calendar feature

- Improved Gantt Chart functionality featuring:

- Milestone controls for Supply and Demand rows

- Resource tooltips with capacity mode information

- Pre-filled field information in the Allocate Operation panel

Interoperability

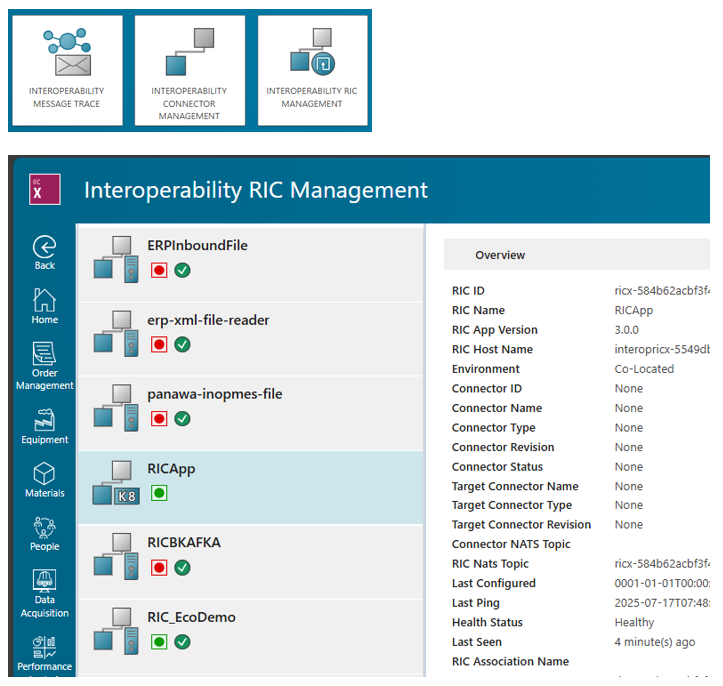

- Centralized management of Remote Interop Connectors (RICs)

- Support for co-located deployment of RIC in Kubernetes

RICs can now be configured and observed centrally from a new page in the Interop App. It is also now possible to deploy a Kafka RIC in Kubernetes together with Interop App.

If you are a decision-maker in an SMB in discrete industries and resonate with the challenges discussed, consider exploring Siemens’ new solution Opcenter X. It might just be the catalyst your company needs to leap into the future with confidence.

Try our product through our Trial page, or by requesting a demo.