What’s new in Opcenter Intra Plant Logistics 2510

Expanding transport flexibility, enhancing inventory control, and strengthening platform readiness

Opcenter Intra Plant Logistics (IPL) 2510 focuses on logistical flexibility and core platform readiness for modern intralogistics environments. This release extends Transport Management to cover forklifts, tugger trains, and fully manual moves; introduces a new Transport Execution App; completes integration with Siemens SIMOVE for AGV orchestration; and delivers full Units of Measure and decimal quantity support across logistics and MES integrations. Additional enhancements include configurable factory hierarchy for standalone deployments, end‑to‑end Country of Origin compliance, and a series of usability, API, and scanning improvements.

Key highlights

- Support for non‑AGV transports: forklifts, tugger trains, and manual moves

- New vehicle assignment logic and execution visibility for non‑AGV operations

- Full SIMOVE integration via TOM API to orchestrate AGVs with VDA 5050

- Full Units of Measure and decimal quantity support across IPL and MES touchpoints

- Factory Hierarchy Configuration to support standalone deployments

- Country of Origin compliance across registration, blocking, commissioning, and machine verification

- Updated licensing logic for AGV and non‑AGV vehicles based on concurrent active vehicles

- Usability, REST API, and scanning improvements across inventory and transport

Transport Management: Forklifts, tugger trains, and manual moves

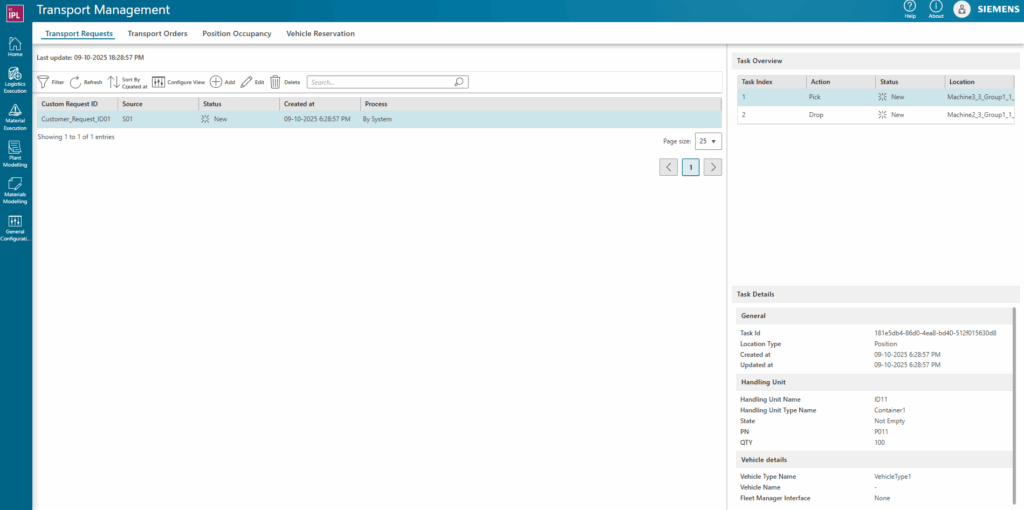

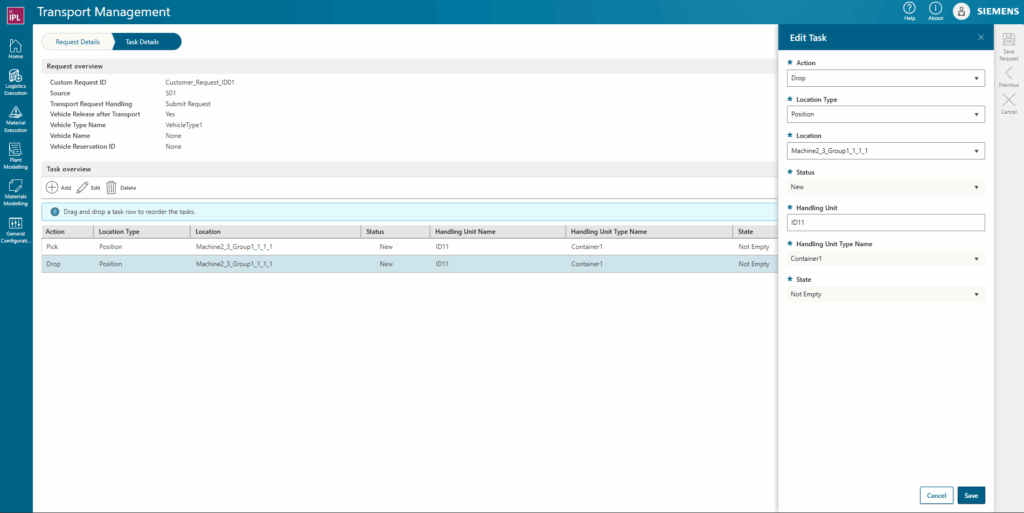

IPL 2510 extends Transport Management to support non‑AGV vehicles—including forklifts, tugger trains, and fully manual transports. The system distinguishes AGV and non‑AGV transport types, and Fleet Manager integration handles each accordingly. Vehicle reservations are tracked with this separation and reflected in Transport Orders, Requests, and the Reservation view.

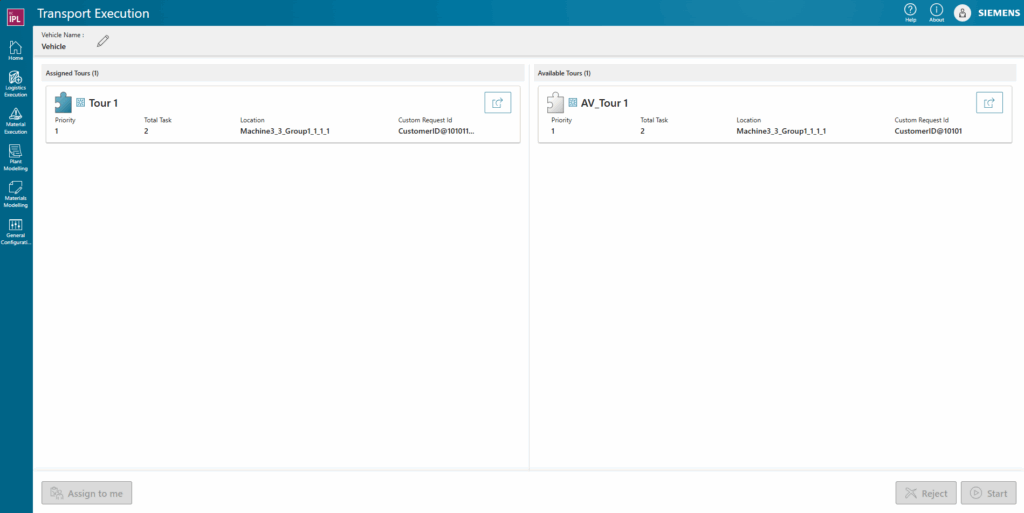

A new vehicle assignment logic enables IPL to allocate all eligible vehicles for a tour when a request does not specify a vehicle. Alternatively, drivers can select from available tours using the updated Transport Execution App. This setup improves flexibility and utilization in mixed‑fleet environments.

Licensing for both AGV and non‑AGV vehicles is now based on the number of active vehicles in concurrent execution, providing more accurate license management.

Benefits:

- Greater transport flexibility in mixed‑fleet operations

- Better resource utilization and reduced downtime

- Improved transport visibility and execution efficiency

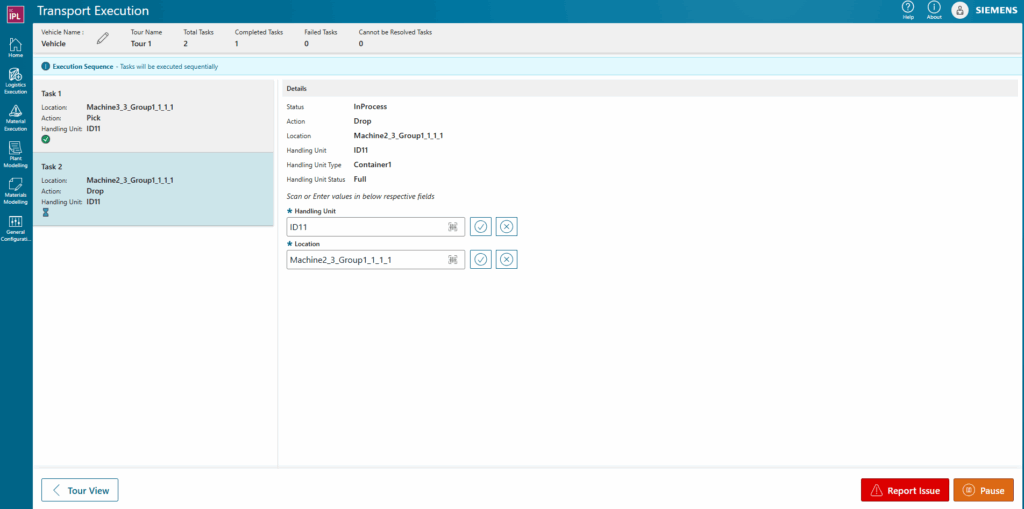

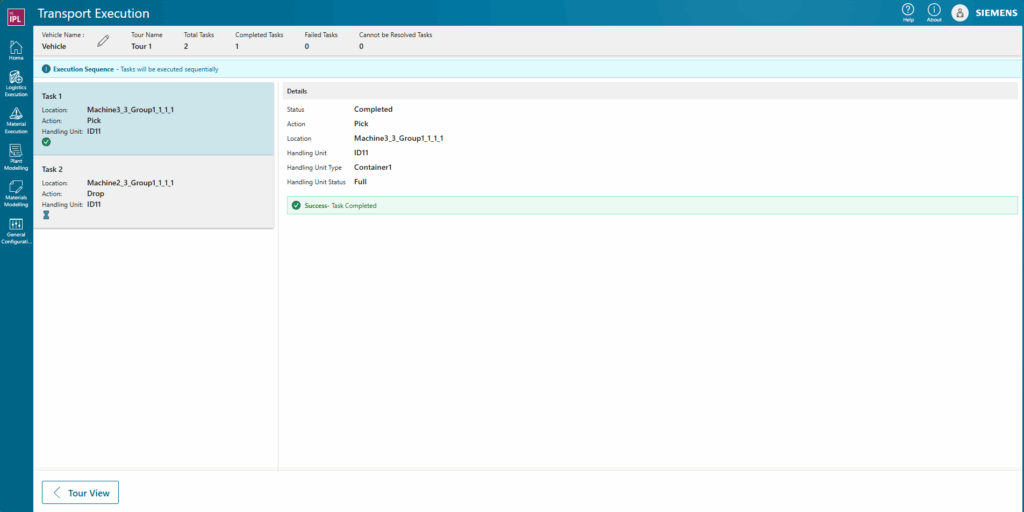

Transport Execution App: Real‑time, scan‑enabled workflows

The new Transport Execution App in the IPL Portal provides a simplified execution interface designed for tablets or vehicle‑mounted PCs. Operators can view assigned or expected tours per vehicle, execute tasks (e.g., pickup and delivery) using scan‑enabled workflows, and report task status changes.

Key execution views and capabilities:

- Vehicle‑centric tour list for current and upcoming tasks and involved transport units

- Task execution with barcode scanning at each step for accurate tracking

- Real‑time synchronization with Storage and Transport Occupancy views when handling units are scanned for pickup or placed into storage

Benefits:

- Improved execution visibility

- Higher vehicle utilization

- Faster response to issues and disruptions

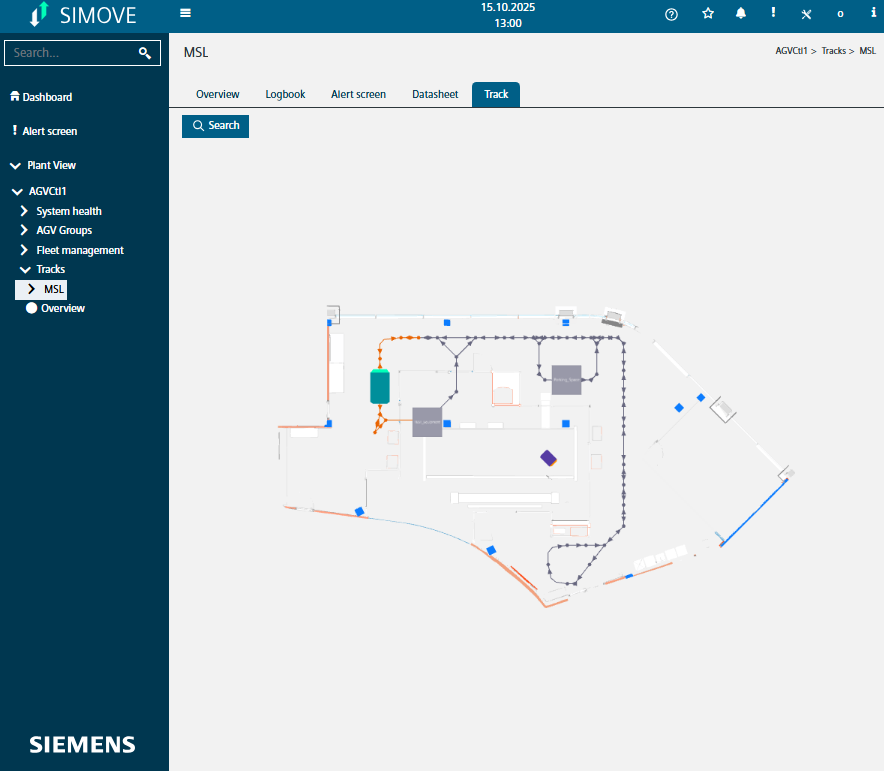

SIMOVE integration: AGV orchestration via VDA 5050

SIMOVE is Siemens’ fleet manager for AGVs. With IPL 2510, integration with SIMOVE via the TOM API is complete. IPL can send transport requests, receive execution status updates, and coordinate with SIMOVE‑managed fleets. This extends out‑of‑the‑box compatibility to a broader range of AGV vendors that support the VDA 5050 standard without custom integrations.

Transport–Inventory integration: Continuous, bi‑directional sync

IPL 2510 delivers full integration between Transport Management and Inventory. An initial state synchronization aligns handling unit locations and statuses across both modules. After this, real‑time, bi‑directional updates keep inventory data current as transports are executed.

Enhancements include:

- Inventory‑driven handling unit parameters visible in Transport Management UI

- Smart Scanning validations with immediate user feedback

Benefits:

- Real‑time inventory synchronization and improved data accuracy

- Enhanced traceability across the shop floor

- Greater operational efficiency

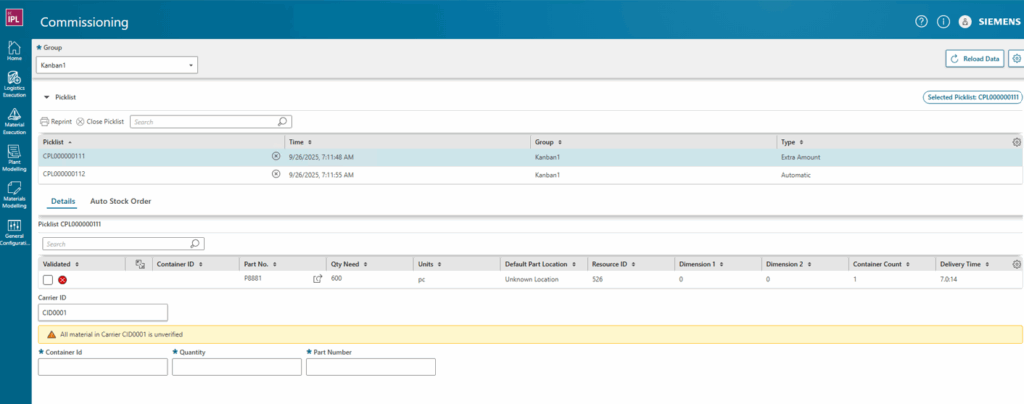

Units of measure: Standardized, precise quantity handling

This release introduces full support for Units of Measure (UoM) across logistics and MES integrations, covering mass, volume, length, area, and count. Part definitions and unit assignments can be imported from MES to keep systems synchronized.

Key capabilities:

- Automatic unit conversions at container registration if scanned units differ from part definitions

- UoM handling within commissioning flows (splitting, combining, issuing)

- Unit conversion at MES integration points (Material Requests and Material Consumption reporting)

Benefits:

- Consistent, accurate quantity management across IPL and MES

- Reduced errors in material handling and reporting

Decimal quantity support: Precision for advanced manufacturing

IPL 2510 adds full support for decimal quantities across applications and APIs, building on UoM capabilities. This is essential when conversions (e.g., yards to meters) result in non‑integer values, and it addresses precision needs common in discrete manufacturing, battery production, automotive, and aerospace.

Implementation notes:

- Relevant database fields shift from integer to decimal; existing data is retained and converted

- Reverting to older IPL versions may result in precision loss

- New APIs fully support decimal quantities; legacy APIs remain for backward compatibility

Benefits:

- Greater flexibility and granularity in material measurement

- Stronger fit for industries requiring precise quantity handling

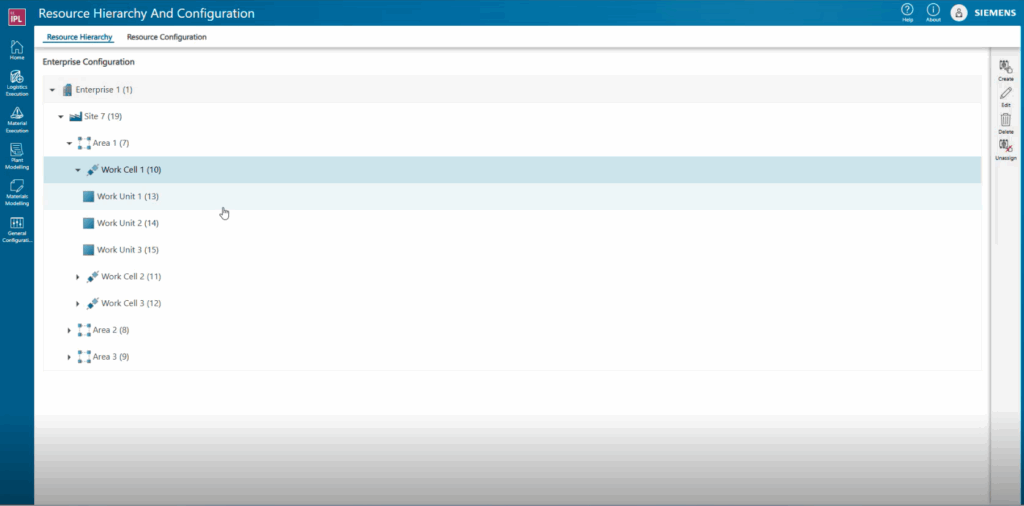

Factory hierarchy configuration: Toward standalone deployment

A new Factory Hierarchy Configuration page in the IPL Portal enables creation, editing, and deletion of factory hierarchy structures without requiring an MES connection. The interface includes:

- Resource Hierarchy tab

- Resource Configuration tab

Users can define logical resources and physical locations used across IPL applications, and unassign resources while preserving their configuration for dynamic environments.

Benefits:

- Increased deployment flexibility and faster rollout

- Simplified maintenance in brownfield or phased deployments

- Progress toward running IPL standalone

Country of origin support: End‑to‑end compliance

Country of Origin (CoO) is now supported across the full flow:

- Incoming Material Registration: new CoO field (manual entry or barcode), with configurable barcode format

- Validation of Manufacturer Part Number alongside CoO; optional mandatory enforcement

- Blocking logic based on CoO with scheduler awareness (blocked materials excluded from pick suggestions)

- Commissioning checks to prevent use of blocked materials

- Machine‑level verification in SFM and MMA: materials blocked by CoO rules prevent processing and trigger warnings

Benefits:

- Stronger traceability and compliance

- Quality control across registration, commissioning, and production

Other enhancements

- New REST APIs for inventory management and updates to support programmatic interactions

- Transport Request View UX refresh for improved navigation and usability

- MSD‑level scanning in IMR, enabling scanning of moisture‑sensitive devices and automation through the IPL plugin

- Container type properties:

- Container type selection in IMR material properties during registration

- Container type property available in the MM configuration tool for better control of material handling workflows

Conclusion

Opcenter Intra Plant Logistics 2510 expands transport flexibility across mixed fleets, strengthens inventory accuracy through real‑time synchronization, and advances platform readiness with UoM, decimal quantity, and factory hierarchy configuration. Country of Origin compliance and focused usability and API improvements round out a release designed for precision, scalability, and operational control.

- Ready to explore IPL 2510 for your operation? Contact your Siemens representative or your Siemens partner to discuss deployment options and next steps.

Learn more about Opcenter IPL

Discover the power of Opcenter Intraplant Logistics to optimize your material flow from warehouse to factory floor. With real-time inventory management, smart JIT material replenishment, and special material management, you can increase line performance, maintain inventory accuracy, and ensure smooth material flow. Learn more about how this solution can revolutionize your intralogistics capabilities.

Learn more about supply chain management and logistics

A successful supply chain is not only relevant for intralogistics – Siemens has also solutions to support you with your intelligent and digital supply chain management:

- Siemens Digital Logistics

- Supply Chain Suite – PLANNING AND SIMULATION

- AX4 – COLLABORATION AND EXECUTION

- Supply chain consulting – Empowering excellence in logistics

- XCargo – the swiss army knife of logistics