What’s new in Opcenter Execution Process 2507

Seamlessly integrate process recipes & discrete BOPs for end-to-end traceability, accelerated NPI, and data-driven continuous improvement.

Manufacturing processes are characterized by high variability across industries and niches, and customers often implement variations of standard processes across production plants and/or lines. Moreover, production processes are not fixed in time: They evolve and are constantly being optimized to reduce waste, improve productivity and answer changing market conditions.

Additionally, it is critical to have user acceptance to successfully deploy new information technology systems (IT) in the manufacturing landscape. This means MES solutions need to be flexible and optimized for usability, leveraging collective knowledge and feedback that can be shared by the workforce.

To meet such challenging goals, you can use Opcenter Execution Process for a new and innovative approach, leveraging the power of low code development powered by the Mendix™ app platform combined with the rich out-of-the-box (OOTB) set of MES data model and functional transactions for the CPG and process industries. Opcenter and Mendix are part of the Siemens Xcelerator business platform of software, hardware and services.

Capabilities

This version introduces several exciting capabilities aimed at enhancing your operational efficiency and productivity. The Process capabilities are generally available based on the new enterprise model.

The technological stack is common with Opcenter Execution Discrete allowing the management of different production processes, from chemical to mechanical assembly, with a single MES instance, supporting full end-to-end traceability of the final product.

You can benefit of a digital enterprise solution that offers all the capabilities of the 2 products in one single configuration environment, allowing the configuration of Process recipes and Discrete BOPs with a material genealogy from the final product to the raw materials.

The enterprise solution will be enriched in the next versions with out of the box capabilities for Process Customers by providing:

1) a native integration with Teamcenter Easy Plan to enable efficient collaboration and synchronization between project planning and execution, introducing 3 main differentiators:

- a faster NPI (New Product Introduction) and timely reaction to change

- collaboration between lab, manufacturing and execution lead to better decision making and time saving

- improved accuracy, quality, and traceability

2) Statistical Process Control analysis against quality and manufacturing data to analyze data trends and patterns, make data-driven decisions, and implement continuous improvement initiatives

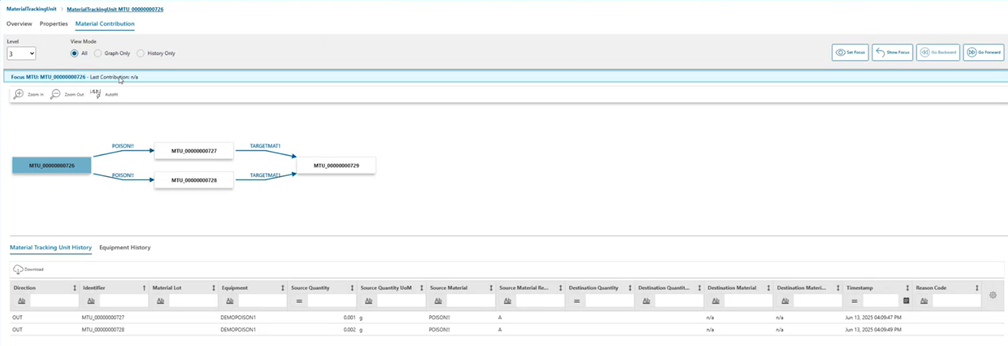

3) a native integration with Insights Hub to provide a cross- system and cross-site traceability, containment capabilities and increase manufacturing performance

4) Non-Conformance, Tools mng, Skill and Certifications

UI industry templates MX-powered

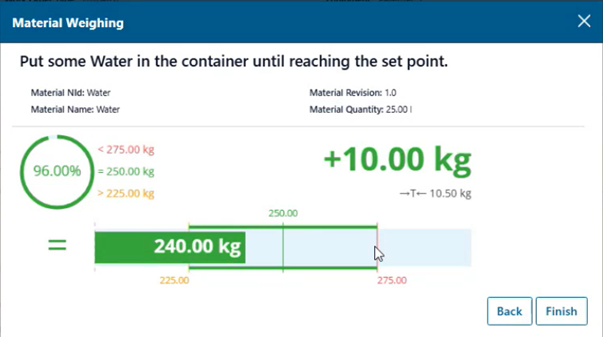

Traditional UI built on standard web technologies lacks flexibility and requires significant development effort for customization. This slows down adaptation to evolving operational needs and user preferences. In this version we focus on dedicated screens for weighing operations with scale connectivity and a Material/Equipment history.

Adopting Mendix enables rapid UI development and customization. New template will provide:

- Weighing control integrated in the Material Preparation and Consumption Task (scale connectivity via OPC UA interface)

- Material and Equipment History

The operator is guided in weighing activities to prepare the material to be consumed.

Material Recall can be easily managed with Equipment and Material History.

TCO reduction: open-source PostgreSQL support

Choosing the right open-source software can give you access to enterprise-level features, without the associated price tag.

Now PostgreSQL can be used to configure both production and archival databases.

Due to the nature of the development model, with its focus on open standards, open-source software vendor lock-in is highly improbable.

Want to learn more about Opcenter Execution Process?

Using Opcenter Execution Process as a Manufacturing Operations Management (MOM) platform enables seamless integration with scheduling, quality, and manufacturing intelligence, which delivers interactive dashboards for analysis of production data.

For New Product Development & Introduction, Opcenter Execution Process enables the transformation of recipes from “generic” specifications to detailed “master” instructions, ready for order scheduling and execution. Find out more about Opcenter Execution Process.