What’s new in Opcenter Execution Process 2207

Providing a state-of-the-art platform to deploy predefined industry templates

Opcenter™ Execution Process (EX PR) software is the Siemens manufacturing execution system (MES) for the consumer-packaged goods, food and beverage and chemical industries. Using Opcenter Execution Process can help you increase traceability, manage orders more efficiently and monitor production in real time – all based on a state-of-the-art platform and application approach.

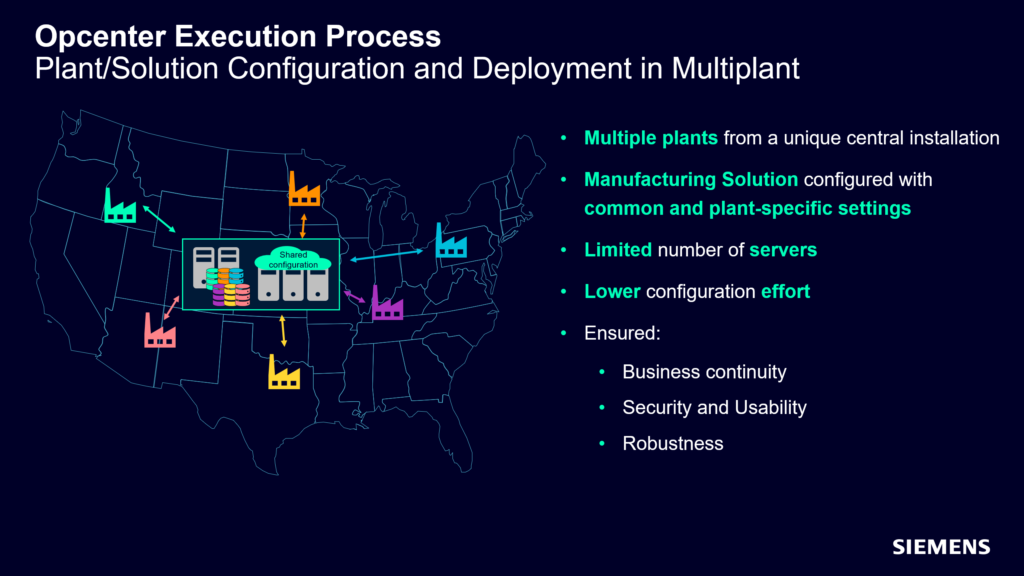

Opcenter Execution Process 2207, which is part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services, is equipped with a new multi-plant architecture that allows the system to manage multiple factories from a unique central installation. In a multi-plant scenario, users can configure the manufacturing solution with common settings and options for plant-specific tuning and runtime operations to adopt a multitenancy approach.

Opcenter Execution Process 2207 brings you the following benefits:

- Provide a state-of-the-art platform to deploy predefined industry templates

- Synchronize business practices and integrate automation and batch execution

- Deliver just-in-time and intuitive execution support for complex shop floor operations and seamless user experience for production operators

- Integrate quality tests in lot quality control and information exchange with laboratory personnel

- Facilitate advanced planning and scheduling of operations and resources to optimize equipment use and increase efficiency

Opcenter Execution Process 2207 brings a lot of valuable capabilities, here are some of them:

- Configure plant solutions and deploy in multi-plant

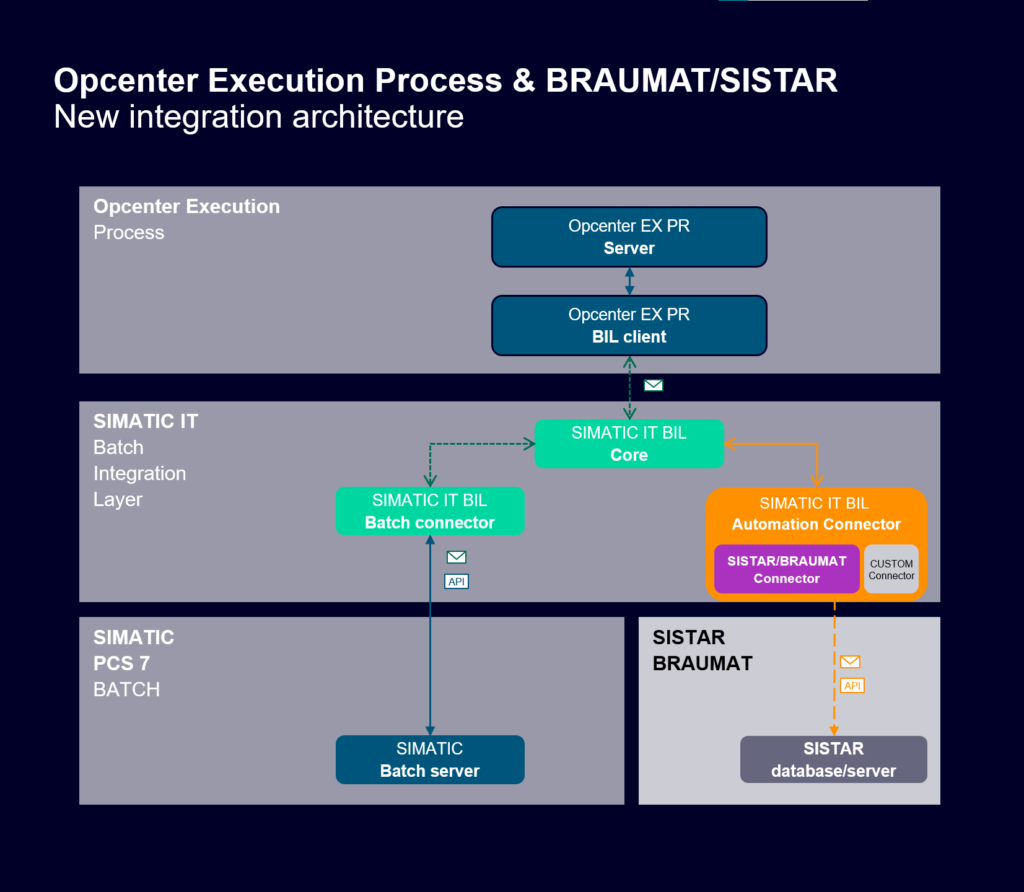

- Integrate with process control systems for food and beverage – BRAUMAT/SISTAR

- Execute failsafe quality with inspection orders

- Improve support and sustainability

- Use a new licensing model

Already using Opcenter Execution Process? See what’s new in version 2207.

Want to learn more? Using Opcenter Execution Process as a MOM platform enables seamless integration with scheduling, quality, and manufacturing intelligence, which delivers interactive dashboards for analysis of production data.

For New Product Development & Introduction, Opcenter Execution Process enables the transformation of recipes from “generic” specifications to detailed “master” instructions, ready for order scheduling and execution. Find out more about Opcenter Execution Process.