What’s new in Opcenter Execution Pharma 2511

Comprehensive web-based work instruction execution with enhanced operator cockpit and streamlined process management

Summary

Opcenter™ Execution Pharma (EX PH) software serves as the foundation for leading pharmaceutical manufacturers and innovators that want to enable rapid change, lean paperless manufacturing, consistent quality output and higher profit margins. Offering native integration between the manufacturing execution system (MES) and the distributed control system (DCS) layer, Opcenter EX PH expedites the design, execution and review of the manufacturing process steps and provides flexibility in the master batch record (MBR) design process.

Opcenter EX PH 2511, which is a part of the Siemens Xcelerator business platform of software, hardware and services, enables users to regulate and manage processes without paper-based procedures or documents. With Opcenter EX PH, you can easily configure and leverage out-of-the-box (OOTB) functionality to facilitate design processes even if the user does not have specific information technology (IT) skills.

Powered by an advanced workflow engine and easy-to-use electronic work instructions (EWIs), manufacturers can use Opcenter EX PH to direct manufacturing while recording and centralizing everything required for a completed batch record. Further, leveraging MBRs facilitates managing key process parameters.

As the system is fully compliant with U.S. Food and Drug Administration (FDA) and Good Manufacturing Practice (GMP) regulations, manufacturers can optimize batch manufacturing processes and streamline resources such as user guidance, equipment allocation and standard operation procedures (SOPs). The software can also systematically control the manufacturing execution at all stages, including human operations or operations controlled by the automation layer.

Using Opcenter EX PH enables manufacturers to reliably acquire critical process data. Additionally, users can forward and backward search using the genealogy and audit trail tools and review product batch records by exception to provide faster and more efficient product releases. This significantly reduces the manufacturing review and release times and facilitates a faster time-to-market.

Opcenter EX PH 2511 includes several enhancements, delivers new OOTB features, eases the engineering requirements and reduces the total cost of ownership (TCO) of a customer’s system.

Benefits

• Execute rich operating text via web browser without client installation

• Manage manufacturing annexes and alerts directly from the Operator Cockpit with full review capabilities

• Simplify process instruction rollout with enhanced import analysis and automated parent PI version management

• Reduce deployment time and effort through extended installation automation

• Improve system scalability with configurable service execution and comprehensive monitoring

Capabilities

Web-based Work Instruction

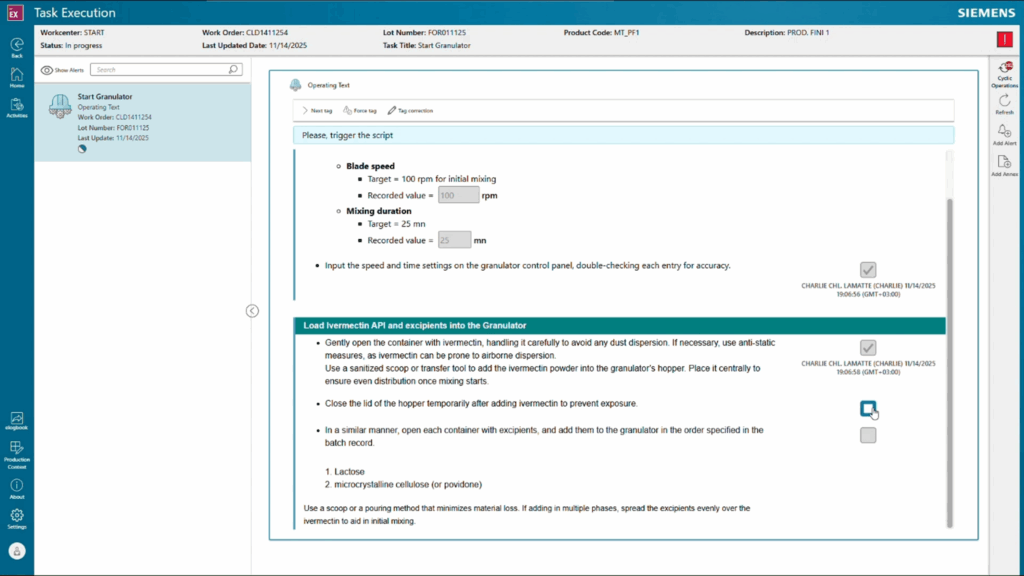

With Opcenter EX PH 2511, we deliver a significant milestone in our innovation journey: web-based execution of operating text compatible with the rich client PI Process application. Web-based Work Instruction is compatible with the operating text running in PI Process, there is no need to redesign the existing Process Instruction to adopt the new capability.

This release provides a comprehensive set of instruction tags supporting paper-on-glass scenarios, enabling operators to execute manufacturing operations directly from their web browser without requiring client installation.

The state-of-the-art user experience (UX) allows operators to interact with all generic tags, including: Text, Numeric, Time, Checkbox, Multi-value, Electronic signature but also advanced tags to interact with equipment and automation.

To support process-specific requirements, the system includes script tag capabilities, allowing teams to easily create managed script extensions that deliver custom functionality tailored to their manufacturing needs.

Advanced features such as conditional execution of sections are fully supported, providing the flexibility required for complex pharmaceutical processes. Instruction sections may be repeated, skipped based on previously value entered by the operator or exchange with an external system.

- Enhanced value correction

The new value correction capability makes it easy for operators to modify entered values with significantly reduced clicks. This streamlined approach minimizes disruption to the operating text structure while ensuring the high level of traceability required for the pharmaceutical industry.

- Seamless deployment

The web-based work instruction execution can be used without redesigning existing Process Instructions or Operating Text. It is accessible through the web-based Operator Cockpit, which simplifies the deployment of operator workstations by eliminating the need for rich client installations.

Benefits

- Web-based execution without client deployment

- Compatible with existing Process Instructions

- Efficient value correction with full traceability

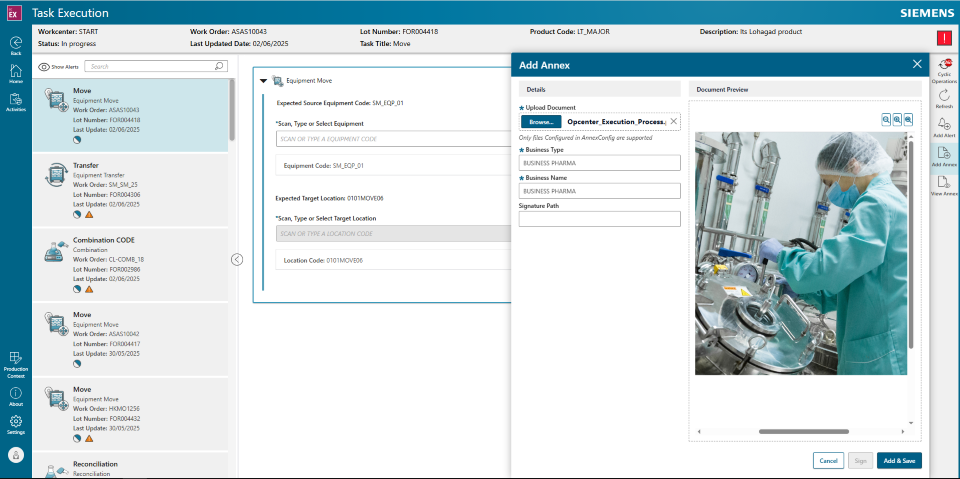

Annex and alert management at operators’ fingertips in Operator Cockpit

We continue to extend our immersive cockpit for manufacturing operations, delivering a comprehensive web-based experience that consolidates critical operator activities.

- Manufacturing annex upload and management

With this release, operators gain a brand-new UX experience to manage annexes directly from their web browser. Operators can select specified documents and attach them as annexes to the work order, where they become part of the batch record.

From the same application, supervisor & reviewer can review and sign the conformance of annexes with an intuitive, modern interface. The annex lifecycle has been extended to support rejection scenarios, allowing operators to reject annexes that do not conform with process requirements.

- Alert review process

In addition to the comprehensive annex management capabilities, the alert functionality has been extended with a complete review process. Operators can now review and sign alerts—whether deviations or remarks—directly from the web application via the signatory paths defined during engineering.

This consolidation of annex and alert management within the Operator Cockpit eliminates the need to switch between multiple applications, improving operator efficiency and reducing the potential for errors.

Benefits

• All operator activities consolidated in one web application

• Complete annex lifecycle management including rejection

• Streamlined alert review process with electronic signatures

• Improved operator efficiency and reduced application switching

Simplify Process Instruction rollout

- Process Instruction import enhancements

The transport of Process Instructions from one environment to another is an essential capability during the engineering phase and for rollout programs. Following customer requests, we have significantly enhanced the PI import module.

The import report now provides more detailed and better understandable information, highlighting critical and important operations for an easy review.

Additionally, we now support the capability to import Process Instructions from different Opcenter Execution Pharma versions, not just different updates within the same release. This enhancement provides greater flexibility for customers managing multiple system versions across different sites or during phased upgrade programs.

- Automated parent PI version upgrade via API

The flexibility to adapt Process Instructions is essential to support project implementation while manufacturing operations are ongoing. To ease this process, we introduce a new API that automatically upgrades the version of the parent Process Instruction when a sub-process or script is updated.

This eliminates the need for dozens of manual clicks to upgrade the version of Process Instructions that call the improved sub-processes, significantly reducing engineering effort and the potential for human error.

Benefits

• Clearer import analysis with highlighted critical actions

• Support for cross-version PI imports

• Automated parent PI version management

• Reduced engineering effort and errors

Improved serviceability, supportability and DAID

With each release, we continue to simplify installation and reduce the operational footprint of Opcenter EX PH. With version 2511, we extend our automation capabilities to cover additional deployment scenarios.

- Automated installation enhancements

API services and Mendix app configuration now have their own installation automation steps, which can be combined with all other automated steps to streamline the complete installation of Opcenter Execution Pharma in any complex infrastructure.

Additionally, it is now possible to update system parameters via command line. At the end of the automated installation, you can easily update system parameter values to support your business requirements by simply adding a script.

- Service configuration and monitoring

Some Opcenter Execution Pharma deployments with a high number of external integrations may require significant load on the integration module. With this release, we have added the capability to configure execution categories for scripts.

For example, you can prioritize the execution of business-critical scripts—such as those handling real-time material tracking or quality control data—compared to less time-sensitive scripts like periodic reporting or data archiving tasks. This ensures that critical manufacturing operations always receive the necessary system resources.

In addition to this configuration capability, we have added comprehensive metrics on task execution. Monitoring task execution is essential to ensure good scalability while maintaining optimal performance and a small footprint for the different tasks executed by the servers.

- Technical upgrades

As usual, this release includes several bug fixes and component upgrades. Notably, with this release we are now supporting Mendix 10.24, which is the latest Mendix Long Term Support (LTS) release, ensuring customers benefit from the latest platform capabilities and extended support lifecycle.

Benefits

• Reduced installation time through extended automation

• Flexible system parameter configuration via command line

• Optimized system performance through script prioritization

• Better scalability through comprehensive monitoring

• Latest Mendix LTS support for extended platform lifecycle

Summary of Opcenter EX PH 2511 enhancements

Web-based Work Instruction – Paper-on-Glass scope

• Compatible execution of rich client operating text via web browser

• Comprehensive tag support: text, numeric, time, checkbox, multi-value, electronic signature

• Script tag for managed custom functionality

• Conditional execution of sections

• Enhanced value correction with reduced clicks and full traceability

• No redesign required for existing Process Instructions

Operator Cockpit

• Manufacturing annex upload and management

• Annex review and signature with rejection capability

• Alert review process with electronic signatures via signatory paths

• Consolidated web-based operator experience

Process Management

• Enhanced PI import with detailed, understandable reports

• Cross-version PI import capability

• Automated parent PI version upgrade via API

Serviceability & Supportability

• Automated installation for API services and Mendix apps

• System parameter configuration via command line

• Configurable script execution categories for prioritization

• Task execution metrics and monitoring

• Mendix 10.24 LTS support

This version also includes several upgrades to technical aspects, enhanced security and bug fixes.

Want to learn more? With Opcenter Execution Pharma Siemens Digital Industries Software has developed a dedicated MES solution for the pharmaceutical industry that enables complete paperless manufacturing and full electronic batch recording.

Opcenter Execution Pharma provides advanced features for designing, streamlining and managing production operations and processes – both manual and automated – via seamless integration between the MES, automation and enterprise resource planning (ERP) systems.

Find out more about Opcenter Execution Pharma.