What’s new in Opcenter Execution Electronics 2410

Continued improved shopfloor user experience and expanded portfolio integration

Summary

Opcenter™ Execution Electronics (OC EX EL) software is a complete digital manufacturing solution for the electronics industry. It is built on an industry-leading manufacturing execution system (MES) platform for the electronics, medical device and semiconductor industries. Opcenter Execution Electronics is used in the electronics value chain for printed circuit boards (PCBs), mechanical and box-build processes.

The solution includes best-in-class manufacturing operations management (MOM) capabilities such as manufacturing execution, quality management, material management, planning and scheduling and manufacturing intelligence. This facilitates directly connecting to machines and production lines.

Electronics manufacturers can quickly execute new product introductions (NPIs) and reduce time-to-market, which increases their competitive advantage in a rapidly changing, consumer-driven marketplace.

Using Opcenter Execution Electronics 2410 in conjunction with Mendix™ low-code platform, which are part of the Siemens Xcelerator business platform of software, hardware and services, helps deliver new enhancements to improve the application’s capabilities and security. The Mendix low-code development framework and community of prebuilt marketplace components make it easy to create and deliver powerful, optimized and role-based apps.

Opcenter Execution Electronics 2410 offers new and improved shop floor user interfaces, numerous functional enhancements, improved integration, simplified installation and deployment, and much more.

Benefits

- Provide greatly enhanced role-based user experience

- Improved digital thread portfolio integration

- Improve deployment and scalability

- Improved machine connectivity

- Improved operator efficiency

Capabilities

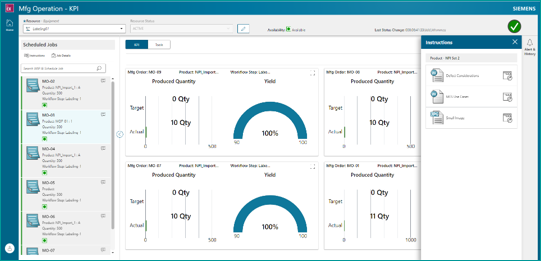

Real-time manufacturing operation page, Mendix module

- Enhancements

- Display scheduled orders & KPI’s for a specific equipment or the entire line

- Improved KPI options: target & actual value for WIP, scaling of yield, yield on / off

- Tool setup management: show required tools, view loaded tools, load & unload tools

- Real time status and message updates & display from Opcenter Connect Electronics

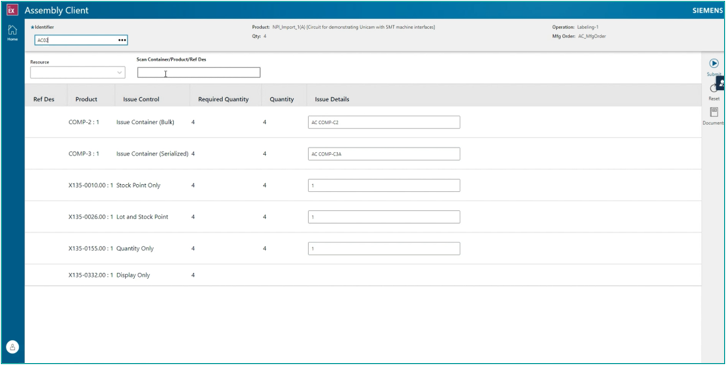

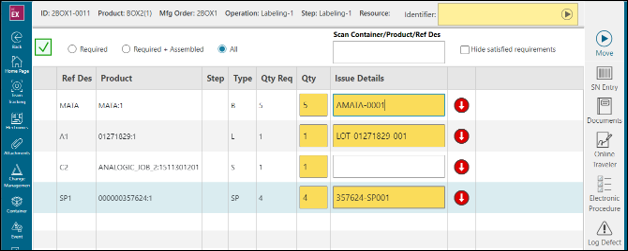

Lean assembly client, Mendix module

- Mendix shopfloor page for highly optimized PCB and Box product assembly

- Primarily leveraging barcode scanning

- Automatic reuse of previous scanned material for current step & manufacturing order, rescan required only if material changed

- Automatic detection when bulk container is exhausted, and a new container scan is required

- Automatic focus on the global or specific entry field depending on serialized, bulk, lot & stock point or stock point only

- Support guided & sequenced assembly

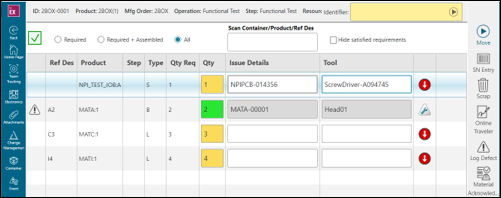

Production/assembly client – Tool traceability

- Functionality to allow collecting the tool used to perform the assembly of materials

- Configure on spec that a tool can be collected during a component issue

- Configure on the product definition or material list Item if the tool value entered should be verified

- Configure that the tool must belong to a specific tool family

Production/assembly client – Fast assembly mode

- Option to automatically fill previous assembled material on the current spec and manufacturing order in the production- and assembly client

- Configurable on the spec

- If enabled, previous scanned material is recorded and filled in to optimize the assembly process. Material only needs to be scanned if changed

Production client – Auto fill data collection

- New option on spec to enable the automatic populating of a data collection from using the last entered values for the same spec and manufacturing order

- No need to enter the same information in the page repeatedly

- Ability to update as required

- Following transactions the production client will automatically pre-populate the previous values

- Move in, move std, rework, close, suspend

Production client additional enhancements

- Ability to filter the “in queue” and “in process” grids by container level (e.g., PCB, box, panel) in addition to manufacturing order or product

- Ability to enter an identifier in the serial number entry screen that contains wildcard (%) characters which will then load and show all matching containers

- Ability in box mode to view the PCB BOM when viewing NPI views for an assembled item

- New column to in Box mode to collect and display the comments when performing a component issue

- Add comments text box to the move and scrap popups to collect comments for the transaction

- Enhance the net view assistance functionality to allow selecting multiple components and see all the nets connected between the selected components

- Add the net view assistance button to the PCB tool bar

- Add a new display option to control the display of fiducials on the CAD display

- Enhance search functionality to support selecting multiple components for logging defects

- Add a new select all button to the container selection popup which will select every row in the grid across multiple pages

Streamlined Opcenter Connect Electronics integration

Reduced software layers:

- Direct Opcenter Connect Electronics to Opcenter Execution Electronics connection

- No Opcenter Connect MOM license required

- Delivery of new driver SDK libraries, OOTB drivers can be adapted/extended at project level

Teamcenter Quality – MES integration phase 1

- Inspection definition download via bill of process to electronic procedures for manual inspection

- Inspection definition download via BOP to the spec for automated inspection

- Escalate a production nonconformance from Opcenter into a Teamcenter Quality issue

Valor Process Preparation Viewer integration, phase 2, PP NPI views

- Technical preview!

- Integration Valor PP 3D Viewer with initial version of NPI Views in Opcenter Execution Electronics Production Client

Power BI reports

- Support Oracle DB for all OOTB reports

- eDHR prompt now accept multiple container entities (container name and serial numbers)

Opcenter Execution Electronics Connect MOM adapter enhancements

- Move all configuration for the NPI and tester adapter into the Opcenter Connect MOM Adapter UI in the Opcenter Connect MOM Portal (instead of configuration file).

- Ability to collect container attributes in the tester adapter when processing the UGSTester format files

- Add the ability to collect & save URL documents and attach them to the defect when processing the UGSTester format files

Electronics container images

- Amazon Web Services (AWS) with Microsoft SQL Server running in a virtual machine (VM) on AWS

- Microsoft Azure with Oracle running in a VM on Azure

Simplified installation

- Simplified Installer, create ansible playbooks for installing Opcenter Execution Electronics

- Supports automated installation

- Ansible-based product installer, including:

- Playbooks

- Prerequisite installation

- Documentation

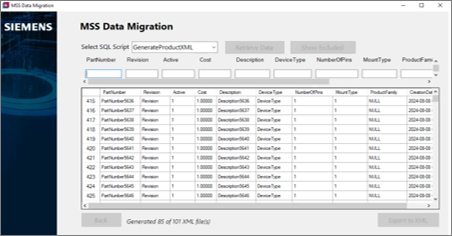

Valor MSS import

- New application to support the import of various modeling data from the Valor MSS. The following data can be imported:

- Products

- BOMs

- Defect Reasons

- Repair Actions

Manufacturing operation page enhancements

- Ability to filter by manufacturing order in addition to selecting a resource

- Add the display of product, lot and resource attributes for the select scheduled manufacturing order

Important Core enhancements

Opcenter IPL integration improvements for Core

- Opcenter IPL integration, support OC EX Core, support OC IPL without NPI and electronics specific data

Semiconductor – Electronics synergy

- The 2410 release is a technical preview of this capability

- Functionality will provide a solution for vertically integrated manufacturers.

- A synergy installation allows the solution to execute all semiconductor and electronics process model functionality within a single environment supporting both solutions in a one installation with all data in one database.

- The general availability release of the synergy functionality is planned for 2504

Other improvements

- Enhance the automatic component issue using materials setup on a resource to support loading a carrier to the resource and issuing from the containers loaded to the carrier

- Update the manufacturing order dispatch page to support attaching URL documents when starting containers

- Update the online traveler page to have the operations grid in a collapsible section

- Update the online traveler page to include a new grid displaying the board to test ID data (recipe) collected during defects recorded by test equipment using the OP EX EL Tester Adapter or OP CN EL integration

Technology enhancements

- Single sign-on enhancements

- Enables single sign-on when embedding the portal within a third-party application, like supervisory control and data acquisition (SCADA)

- Can also directly open a specific page in the portal via a URL and pass in contextual information to that page.

- Example: open electronic procedures page and pass in the name of the container

- REST API enhancements

- Introduces the ability to download files from the shop floor endpoint

- Allows users to retrieve documents in nonconformances via the REST API. Allows for configuring and applying filter tags through a new parameter

- Adds support for specifying the list action attribute in the REST API payload, providing better control over data management operations

- Upgrades the underlying framework from .NET 6 to .NET 8, offering improved performance, security, and compatibility

- Chrome 127+

- Edge Chromium 127+

- Upgraded to .NET 8.0.5

- Upgraded Tiny MCE 6.4.2 to 6.8.3

- Upgraded Xerces from 3.2.2 to 3.2.3 in Designer 2

Please see Opcenter Execution Core and Medical Device and Diagnostics and Opcenter Execution Semiconductor 2410 SFB for more details on new core functionalities.