What’s new in Opcenter Execution Electronics 2210

Using Opcenter Intra Plant Logistics to improve configuration efficiency for the MES

We are excited to announce that the latest version of Opcenter Execution Electronics has been released!

Opcenter Execution Electronics is used in the electronics value chain for printed circuit board (PCB), mechanical and box-build processes. It is part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services.

The solution includes best-in-class manufacturing operations management (MOM) capabilities such as manufacturing execution, quality management, materials management, planning and scheduling and manufacturing intelligence. This facilitates direct connectivity to machines and production lines.

Electronics manufacturers can rapidly provide new product introduction (NPI) and reduce time-to-market to increase their competitive edge in a changing consumer-driven marketplace.

Opcenter Execution Electronics version 2210 provides an improved integration with Opcenter Intra Plant Logistics, technology improvements and new features that increase efficiency in electronic production.

Opcenter Execution Electronics 2210 brings a lot of valuable capabilities, here are some of them:

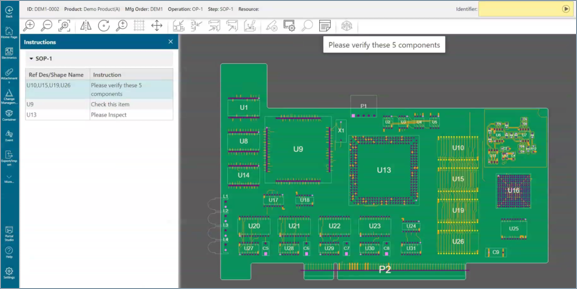

- Production client enhancement

- High-volume traceability model

- Opcenter Intra Plant Logistics configuration UI

- Master data management (MDM) upgrade tool for a factory model

- Opcenter Connect MOM error handling workflow

Benefits of Opcenter Execution Electronics 2210:

- Improved configuration efficiency for Manufacturing Execution and Opcenter Intra Plant Logistic

- Increase inspection efficiency and process security

- Reduce total cost of ownership

- Cut deployment time and cost

- Improve serviceability

- Enhance process security and debugging functionality

Already using the Opcenter Execution Electronics? See what’s new in version 2210.

Want to learn more? Opcenter Execution Electronics is a comprehensive manufacturing execution system (MES) for electronic printed circuit board (PCB) and box build. It is designed specifically to help electronics manufacturers respond efficiently to frequent design modifications, short product lifecycles and increased product and production complexities, all while improving quality and reducing the cost of operations.

Opcenter Execution Electronics enables PCB and box assemblers to meet traceability requirements, control production, and integrate the shop floor into their product lifecycle management (PLM) and enterprise resource planning (ERP) system. Learn more about Opcenter Execution Electronics.