Transforming manufacturing operations for SMEs within the discrete industries

Overcoming manufacturing challenges with advanced software solutions

As someone who has accompanied the digital transformation of numerous manufacturers for over a decade, I have seen the manufacturing landscape evolve dramatically and witnessed firsthand how Manufacturing Operations Management (MOM) solutions can revolutionize operations. Small and medium-sized enterprises (SMEs) in Discrete Industries are facing an unprecedented array of challenges that compel them to seek innovative software solutions.

This blog post explores the key hurdles driving these companies towards adopting MOM software, with a particular focus on how Siemens’ new lightweight Software-as-a-Service (SaaS) solution Opcenter X can address these challenges.

Case study: Transforming a SME manufacturer

Imagine a theoretical small- to mid-sized company specializing in industrial machinery production to show how Siemens’ latest solution can revolutionize operations.

Streamlining manufacturing operations

The company has been in business for quite some time, specializing and perfectioning in the production of their products. Despite their expertise, they face significant production inefficiencies, frequent equipment downtimes, and struggle with integrating quality control across their operations.

Their current systems are a mix of outdated and fragmented software and manual processes, leading to disjointed data and lack of real-time visibility.

Never forget: Initial assessment and strategic planning

In my experience, the first step towards the digital transformation of manufacturing operations should always be a comprehensive, yet very practical assessment. For our example company, we identified key pain points which we then turned into an implementation roadmap. The first steps were about providing the foundation to gather a significant ROI and employee acceptance through collecting quick wins.

Implementation of Siemens’ MOM solution

To address these challenges, we implemented Siemens’ new Manufacturing Operations Management solution Opcenter X. The software’s unique abilities to provide fast ROI through a small start without a high investment entry hurdle, integrate seamlessly with existing systems to provide a unified platform for managing production, quality, and data was a game-changer.

Production efficiency improvement

Production inefficiencies and unplanned downtime severely impacted profitability. The company struggled with legacy systems and manual processes that are not equipped to handle the complexities of modern manufacturing. These inefficiencies lead to bottlenecks, reduced throughput, and increased operational costs.

Siemens’ solution enabled real-time monitoring and control of production processes through assisted production operations and in combination with its scheduling capabilities, the company could streamline operations and significantly reduce downtime and increased throughput which led to a substantial increase in productivity and reduced operational costs.

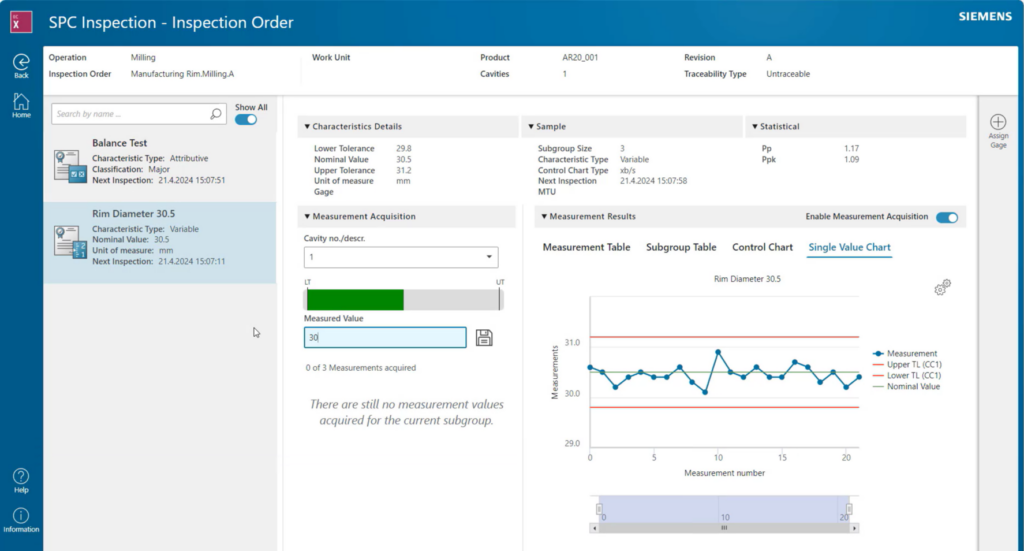

Enhanced quality control

Maintaining high quality and adhering to stringent industry standards is crucial within all industries. Our example company faced challenges in integrating quality control into their production processes and was relying on disparate systems that did not communicate effectively.

By leveraging built in quality checks in the day-to-day work, SPC (Statistical Process Control) analysis and integrated management of non-conformances, the new solution ensures that every product meets stringent quality standards.

Any deviations are immediately flagged, allowing for prompt corrective actions. This leads to a dropped defect rate, higher customer satisfaction, full compliance with industry standards, reduced rework costs and less scrap. In addition, it also streamlined reporting and audit processes, which previously consumed substantial resources and time and enforced accountability across the production chain.

Scalability and flexibility

As our company grew, their production processes needed to scale accordingly. Its traditional systems lacked the flexibility needed to adapt to new product lines and increased production volumes, hindering growth and responsiveness to market demands.

The SaaS nature and the true modularity of the Siemens solution meant that it could scale their operations effortlessly. Whether adding new production lines or adapting to different product specifications, the software provided the necessary flexibility without significant additional investment and configuration.

Data management and insights

Data is the new oil, but our example company was still in the dark ages when it came to data management. Without integrated systems, real-time data collection and analysis became nearly impossible and very time consuming, leading to suboptimal decision-making.

With Siemens’ integrated system, our company could collect, analyze, and leverage data from across its operations, and keep external system always up to date. Real-time insights into production metrics enabled informed decision-making, driving continuous improvement.

Unique advantages of Siemens’ solution

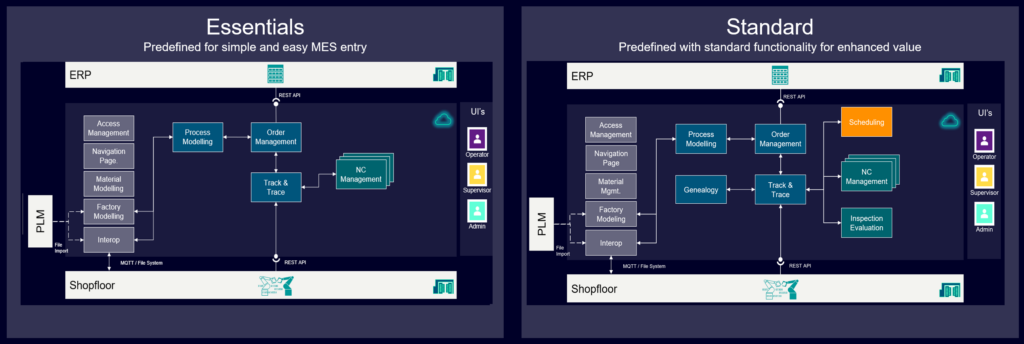

Since Opcenter X is our cutting-edge digital manufacturing SaaS solution which utilizes a modular functional approach to MOM for the SMB market and as such it supported the company with its several unique features during implementation and usage. Here are some of the highlights:

- A User-friendly, platform agnostic interface to quickly adapt to the new system including customization options

- Streamlined decision making through leveraging near real-time data and breaking down data silos through an integrative approach

- Rapid deployment and flexible scaling to start small and scale fast when needed both in functionality and user count

- Minimize up-front costs for software licenses and IT infrastructure, without thinking about the underlying infrastructure

- Protect production data within a highly secure industrial environment

- Frequent functionality additions through frequent software updates and a global network of partners, customers, and Siemens’ vast industry expertise

The products’ current focus lies on SMB discrete manufacturing industries and their core use cases, including manufacturing execution and production operations, quality management operations, production scheduling and operational reporting. However, through an ambitious roadmap, this focus will expand quickly to include functionalities suited for many more.

Conclusion: Embracing the future with confidence

Over the years, I have witnessed firsthand the transformative power of integrating advanced software solutions into manufacturing operations. One memorable project involved a similar SME like our theoretical example, that, after implementing a robust MOM solution, saw a dramatic improvement throughout its KPIs (Key Performance Indicators). These experiences reaffirm my belief in the critical role of digital transformation in driving competitive advantage.

For SMEs embracing digital solutions like Siemens’ latest offering Opcenter X is no longer optional – it is essential. The ability to optimize production, enhance quality, scale operations, and leverage real-time data insights can be the difference between thriving and merely surviving in today’s competitive market. By addressing their unique challenges with tailored software solutions, SMEs can unlock new levels of efficiency, quality, and growth.

If you are a decision-maker in an SME in discrete industries and resonate with the challenges discussed, consider exploring Siemens’ new solution Opcenter X. It might just be the catalyst your company needs to leap into the future with confidence.

We recommend you also watch – Unlocking the power of Digital Manufacturing with Opcenter X, with the recording of our presentation made at HMI2024.

Try our product through our Trial page, or by requesting a demo.