Siemens named a leader in Green Quadrant: Quality Management Software 2025 report

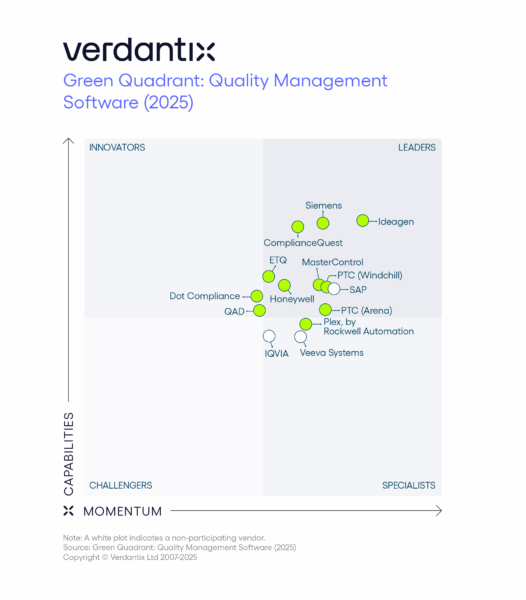

Siemens has been recognized as a leader in the Green Quadrant: Quality Management Software 2025 report by the independent research and advisory firm, Verdantix. The report highlights Siemens for delivering “best-in-class quality management through its well-rounded QMS platform.” Verdantix conducted a detailed, fact-based benchmark of 14 of the most prominent quality management software (QMS) providers in the market, and Siemens emerged as a leader.

Connecting design, manufacturing, and operations for enhanced quality

Siemens’ Quality Management Software (QMS) offering, available as either Teamcenter® Quality software or Opcenter™ X Quality software, is designed to seamlessly connect design, manufacturing, and quality. This integration is crucial for enhancing traceability, standardizing workflows, and supporting continuous improvement across a wide range of regulated industries.

Siemens QMS capabilities are delivered as a part of the Siemens Xcelerator portfolio of industry software. Siemens QMS software supports manufacturers in realizing the comprehensive digital twin, with connections to product lifecycle management (PLM), manufacturing execution software (MES), and the industrial internet of things (IIoT). This powerful combination helps advance and elevate every stage of the quality management lifecycle.

Growing importance of digital tools in Quality Management

April Choy, Industry Analyst at Verdantix, also emphasized the growing importance of digital tools in quality management:

“As the scope of QMS expands beyond traditionally regulated sectors into a broader range of industrial and operational environments, organizations are relying on digital tools to strengthen their capabilities and embed quality management into strategic decision-making. With its storied heritage across a multitude of verticals, platforms such as Siemens’ address key pain points in quality workflows and turn data into actionable insights.”

Driving value through integrated AI-empowered digital solutions

Volker Albrecht, CEO of Siemens Digital Logistics and Business Line Head in Digital Manufacturing, has consistently shared his vision for the future of quality management solutions, emphasizing that quality is an integral part of the continuous workflow his teams strive to implement. As a continuation of this reflection, he commented on this significant achievement:

“The recognition of Siemens as a leader in the Verdantix Green Quadrant for Quality Management Software 2025, we believe, underscores Siemens’ commitment to delivering measurable value for our customers. By integrating advanced AI throughout our comprehensive quality management offering, we are enabling organizations to transform data into actionable insights, streamline operations and achieve continuous improvement. We’re focused on making quality management smarter, faster, and more reliable, solving practical everyday challenges for quality professionals. Our approach empowers manufacturers to enhance application of quality best practices, standardize workflows from design to manufacturing and drive excellence across every stage of the quality lifecycle.”

Empowering your digital transformation journey with Siemens QMS

In today’s competitive landscape, customers demand innovative and sustainable products, produced at a premium quality, with a quick time to market. Navigating these complexities while rapidly developing and delivering top-notch quality products can be challenging.

That’s where Siemens’ Quality Management System (QMS) software solutions come in. The Siemens portfolio supports quality professionals in effectively and efficiently incorporating requirements into the product lifecycle. Through seamless coordination between QMS processes and product development, Siemens helps close the loop product design and production process. Beyond core QMS offerings like Teamcenter® Quality software and Opcenter™ X Quality software, the Siemens quality portfolio also includes:

- Siemens Variation Analysis (VA), available for Teamcenter and Designcenter NX software, supports the validation of geometric dimensioning and tolerancing (GD&T) with tolerance analysis and variation simulation for parts and assemblies.

- Siemens Dimensional Reporting and Analytics (DPV) software, provides capabilities to capture and analyze of engineering and production measurement data, enabling improvement through in-depth analysis of the build process.

Manufacturers can also leverage the Siemens portfolio to extend excellence beyond the company’s manufacturing domain through collaborative partnerships with suppliers. Additionally, the comprehensive Siemens QMS software helps to streamline decision-making processes, reduce errors, and pursue quality excellence.

Ready to elevate your quality management?

With Siemens QMS solutions, manufacturers can:

- Leverage quality and compliance best practices to meet rigorous standards.

- Boost collaboration across multi-disciplinary teams, ensuring everyone is aligned.

- Meet the specific needs of businesses of any size with scalable and flexible solutions.

- Rely on standardized processes while fully supporting industry standards and guidelines.

By utilizing Siemens QMS software, manufacturers can rely on the quality best practices, procedures, processes, and resources needed to meet customer requirements and support relevant quality standards and industry guidelines.

Visit www.siemens.com/qms to learn more about Siemens’ QMS capabilities and how it can benefit your organization.