What’s new in Opcenter Scheduling SMT 2410

Discover the new Gantt chart experience

Opcenter™ Scheduling SMT software is a scheduling tool for the surface-mount technology (SMT) manufacturing industry that seamlessly connects the planner to the shop floor. Opcenter Scheduling SMT, which is part of the Xcelerator™ portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, supports factory planners as they generate production schedules while adhering to a dynamic manufacturing environment and considering frequent, real-time changes that occur in the manufacturing stage, especially in high mix, low volume production or when introducing a new product.

This release offers a new integrated experience that allows users to compare actual production progress with the scheduled timeline

Features & Capabilities

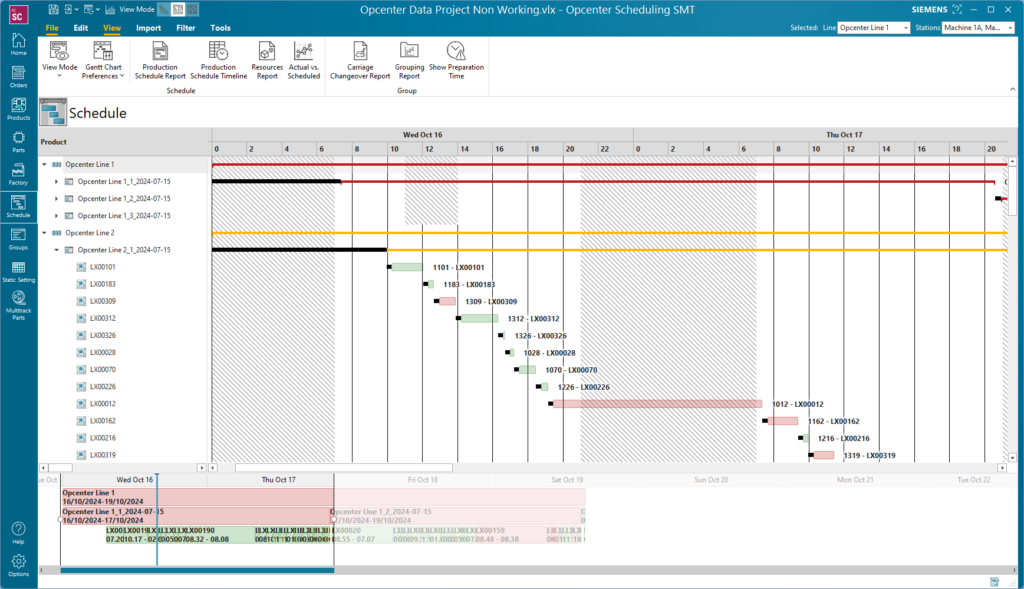

Schedule Gantt Chart

The new Gantt chart experience adds more detail to the schedule. This allows Opcenter Scheduling SMT users to:

- See the factory’s working and non-working time in the Gantt chart to easily understand the schedule

- Recognize time allocated for setup as well as production

- Spot and discern non-working and setup time

Opcenter Intra Plant Logistics Integration

The Opcenter Intraplant Logistics (IPL) integration now supports:

- Access control through the authentication service supported by Opcenter IPL

- Secure communication with Opcenter IPL

Opcenter Scheduling SMT: Intuitive, easy-to-use production scheduling

Set up your constraints using a simple yet comprehensive model that allows you to quickly set up all surface mount technology (SMT) and manual stations in your factory as a basis for conducting simulation. You can easily control optimization parameters, such as due dates, production time and changeovers, and then compare different scenarios. You can then choose the schedule that best fits your needs.

Learning more about Opcenter Scheduling SMT and its unique capabilities has never been easier. We invite you to test drive our solution in a free trial in which everything has been made ready for you. The trial environment includes exercises with detailed steps that will show you first-hand how to get optimal results in a challenging environment.

Opcenter Scheduling SMT combines data from three sources:

- Machine, line configurations and resource availability from the shop floor

- Work orders, schedules and work hours from the enterprise resource planning (ERP) system

- Material availability and location from the supply chain.

The combination of the three enables accurate short-term scheduling. Find out more about Opcenter Scheduling SMT.