Flexible manufacturing 4.0 in industrial machinery

Companies with production sites in countries with high manufacturing costs and wages are investing a lot in automation. Especially in manufacturing of industrial machinery, automating complex processes and eliminating manual labor are benefits of hyper-automation.

Post-manufacturing tasks such as packaging and shipping are also being automated. Essentially, managing production lines becomes more and more important for the modern machine operator.

By automating the process on the shopfloor, flexible adjustments can be made quickly and in response to different factors such as:

- new and urgent incoming orders,

- trials and test runs for new products

- maintenance and cleaning.

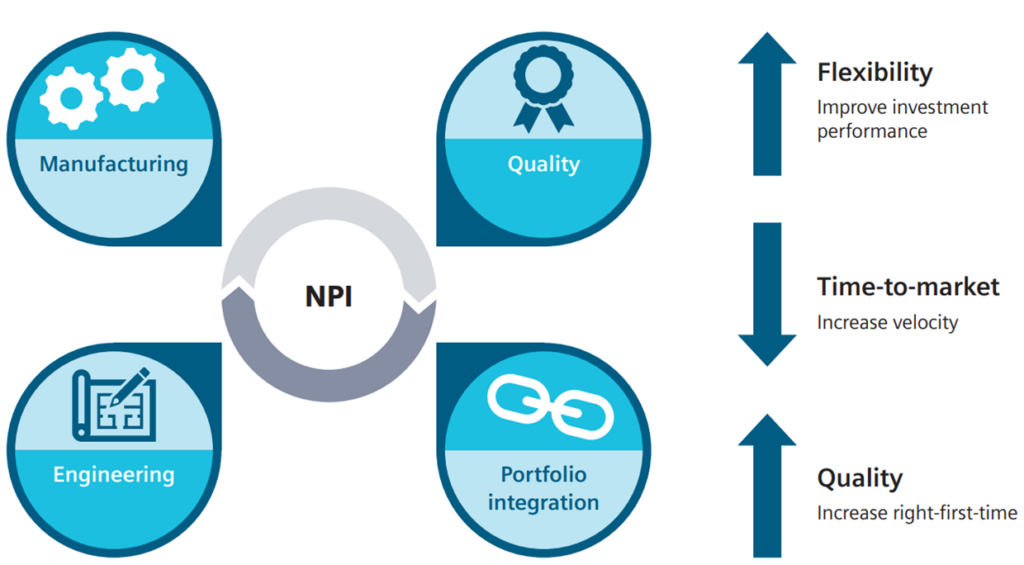

Looking at new product introduction (NPI) process, engineering and placing new products on the market is managed more quickly and accurately as data is collected throughout the process. Monitoring the performance shows the manufacturer what steps in the process can be optimized.

This approach allows for implementing scalable solutions, fulfilling untapped potentials on the shopfloor.

If you want to learn more about trends in manufacturing of industrial machinery and how to react to those, check out this infographic below, of which we covered the part of NPI in depth.

Siemens-SW-Opcenter-Manufacturing-Execution-InfographicFor more information, you can also take a look at our Ebook on transforming industrial machinery manufacturing with the implementation of Manufacturing Operations Management (MOM).