Unlocking the future of Semiconductor Manufacturing

Introduction

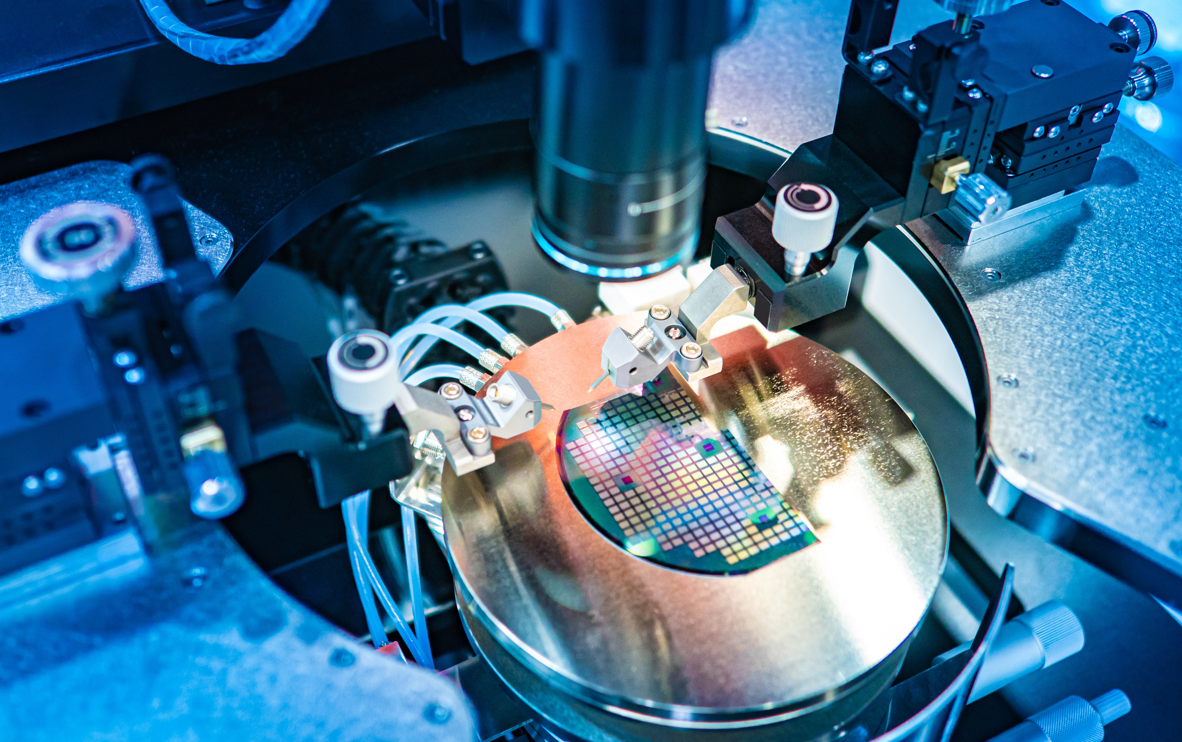

Semiconductor manufacturing sits at the crossroads of unprecedented demand and ever-tightening margins. With applications ranging from automotive electronics and 5G infrastructure to advanced medical devices and consumer gadgets, chipmakers must continually ramp up output while preserving and improving product quality. At the same time, global supply-chain pressures and fierce competition mean there’s little room for error or inefficiency. In this landscape, three core challenges consistently emerge:

- Operational efficiency & production management

- Data integrity & quality control

- Technology adoption & business agility

Below, we unpack each of these areas and explain how software solutions can resolve the specific pain points that chip manufacturers must address to stay ahead.

Operational efficiency & production management in semiconductor fabs hinges on keeping every tool and workflow in lockstep. Yet unplanned equipment downtime, from tool failures or material jams, can halt production lines for hours, while manual, paper-based handoffs introduce transcription errors and obscure true work-in-progress status. Taking into consideration that plants often only plan a few hours of downtime per year, the impact of unexpected production stops is tremendous. Imbalances in material flow and complex scheduling puzzles further create backlogs or starved tools, and planners struggle to align capacity with shifting customer demands and multiple device variants. By embracing digitized dispatch lists, dynamic scheduling algorithms, collaborative planning platforms and closed-loop feedback, fabs can minimize downtime, optimize throughput and accelerate new-product introductions from pilot to volume ramp-up.

Data integrity & quality control become critical when sub-nanometer deviations trigger costly scrap or field failures. Yet process parameters, equipment logs, test measurements and yield dashboards often sit in disconnected IT and OT silos, complicating root-cause analysis and real-time insights without unified genealogy tracking, late-stage defects drag investigations to a crawl, and inconsistent yield definitions across functions fragment accountability. Moreover, delayed metrology and manual inspections leave blind spots that machine-vision and inline sensors can plug. Establishing a single data model with automated traceability, standardized KPIs and preventive in-line defect detection transforms quality management from reactive firefighting into proactive assurance.

Technology adoption & business agility demand that fabs modernize infrastructure and processes without pausing existing lines or incurring excessive risk. Many struggle with incomplete digital twins that limit “what-if” scenario testing, slow prototyping cycles that drag out process development, and scalability constraints tied to capital-intensive expansions. Regulatory compliance across regions adds reporting overhead, while retrofitting legacy assets threatens downtime and integration headaches. By deploying modular MES architectures, edge-compute data collectors and noninvasive integration layers, chipmakers can iterate rapidly, scale flexibly and embed automated audit trails, ensuring that innovation and compliance advance hand in hand.

In an industry where every step and data point matters, overcoming these challenges is not optional, it’s the key to survival. By leveraging integrated, data-driven platforms for planning, execution, analytics, and optimization, semiconductor manufacturers drive higher yields, faster ramp-ups, and greater resilience in the face of market volatility.

In the relentless quest for higher yields, faster cycle times, and greener operations, semiconductor fabs are turning to digital transformation as their compass. It all begins with a solid data foundation, where operations are digitized and capture every machine reading and processing parameter in real time.

Building on this foundation, proactive quality and sophisticated defect-detection systems work hand in hand to prevent problems rather than simply catching them after the fact. This seamless interplay dramatically reduces manual inspections and cuts yield losses, transforming what was once a reactive bottleneck into an agile, self-correcting workflow.

But visibility alone isn’t enough, consistency and scalability require state-of-the-art automation and digital twins. When introducing new products or processes, the digital twin lets you validate and optimize them virtually. This significantly reduces ramp-up risk and shortens time-to-production. With real-time data from MES, manufacturers can constantly monitor WIP flow and equipment status, quickly identify bottlenecks, and plan preventive maintenance.

Underpinning all of this is modern IT architecture and comprehensive traceability. Scalable servers, cloud-native services, and API-driven integrations bind manufacturing execution, enterprise resource planning, and quality platforms into a cohesive whole. Every recipe change, sensor alert, and operator action is logged end to end, so when a defect does slip through, root-cause investigations shrink from weeks to hours, preserving both customer confidence and regulatory compliance.

Yet even the best control systems can falter if equipment health is neglected. That’s where predictive maintenance and intelligent scheduling come into play. By analyzing streams of sensor data and historical maintenance logs, fabs can forecast tool wear and dispatch technicians before unplanned failures occur. Meanwhile, advanced scheduling engines juggle priorities, tool availability, and changeover times to keep lots moving through the right machines at the right moment, maximizing throughput and extending equipment life.

Rounding out the picture, continuous analytics and energy-management platforms turn raw numbers into action. Real-time dashboards beam status updates to shop-floor teams, prompting immediate corrective steps when key performance indicators drift. Simultaneously, energy-use monitors track consumption by tool, line, or entire facility, and automated controls shift nonessential loads to off-peak hours—slashing utility bills and carbon emissions.

By weaving these capabilities into a unified strategy, starting with a data backbone, layering in quality and automation, infusing predictive maintenance, and wrapping it all in smart analytics and sustainability controls—semiconductor manufacturers can create a self-optimizing, resilient fab. The journey doesn’t demand an all-or-nothing leap: begin with a focused pilot on one production line, measure the gains, and then scale out. With each step, you’ll move closer to a fit-for-future powerhouse ready to meet the demands of tomorrow’s technology landscape.

MES – Opcenter Execution

A Manufacturing Execution System (MES) delivers a future-proof platform for digitizing and unifying all production processes and solutions. As a core element of smart manufacturing, it aggregates data from PLM, MOM and APS into a single, harmonized stream, laying the foundation for paperless operations and advanced paradigms like digital twins, the digital thread and closed-loop manufacturing.

Siemens Opcenter Execution Semiconductor replaces legacy point solutions with a comprehensive digitalization backbone, enabling your next leap forward in automation.

The semiconductor industries have long driven the evolution of digital and automated manufacturing. Today’s demands like single-wafer traceability, fully interconnected global production, and real-time transparency for control and quality push traditional systems to their limits. Opcenter Execution Semiconductor (Opcenter EX SM) dissolves “automation islands” and bridges disparate applications, empowering manufacturers to innovate with confidence.

Designed for both front-end (wafer fab) and back-end (assembly/test) operations, Opcenter EX SM offers:

• Extensive out-of-the-box industry workflows

• Flexible configuration to match your unique process steps and equipment

• Full interoperability with PLM, APS, ERP and shop-floor controllers

• Real-time visibility from test results and yield metrics to statistical quality control

By delivering live process data and analytics, Opcenter EX SM establishes the prerequisites for higher quality, greater throughput and continuous improvement. It enables fully automated control, monitoring, material traceability and data acquisition on the shop floor.

Key Benefits of Opcenter Execution Semiconductor:

• Standardize on a single MES for global front-end and back-end sites, as well as suppliers

• Eliminate the costs and risks of outdated, fragmented systems

• Seamlessly integrate with enterprise IT and shop-floor equipment

• Accelerate deployment for rapid return on investment

• Boost yield through built-in quality assurance at every step

• Adapt quickly to process changes and new product designs

• Implement process updates accurately and without delay

Introducing RMS – Recipe Management System

Centrally manage and maintain production recipes and make them available to the production.

In high-mix, high-precision semiconductor fabs, the “recipe” is more than a set of instructions, it’s the DNA that ensures every wafer, every lot and every batch meets exacting specifications. As fabs scale up to hundreds of identical tools and introduce ever-more complex process steps, managing hundreds or thousands of unique recipes by hand becomes a recipe for errors, yield loss and compliance headaches. The Recipe Management System (RMS) is a lightweight, web-based solution that centralizes, validates and tracks every change to your production recipes, making consistency, traceability and rapid iteration not just possible, but effortless.

The RMS solution is very suitable for the semiconductor industry, where complex, manufacturer-specific production recipes are used. These often need to be downloaded to several hundred equipment of the same machine manufacturer within a factory in a reliable way.

Benefits of Recipe Management System solution

It enables efficient management of production recipes and ensures their correct application.

Central administration and deployment

Central tool for managing recipes and downloading them to all machines instead of manual adjustment at each individual equipment

Ensure quality, avoid errors

Validation of recipes to ensure that only approved recipes are used and that no unauthorized recipe adjustments are made to individual equipment

Gain traceability of recipe usage

Traceability of revisions and changes to recipes, such as additions or deletions of parameters

Recipe Management System as part of Opcenter Execution Semicondictor

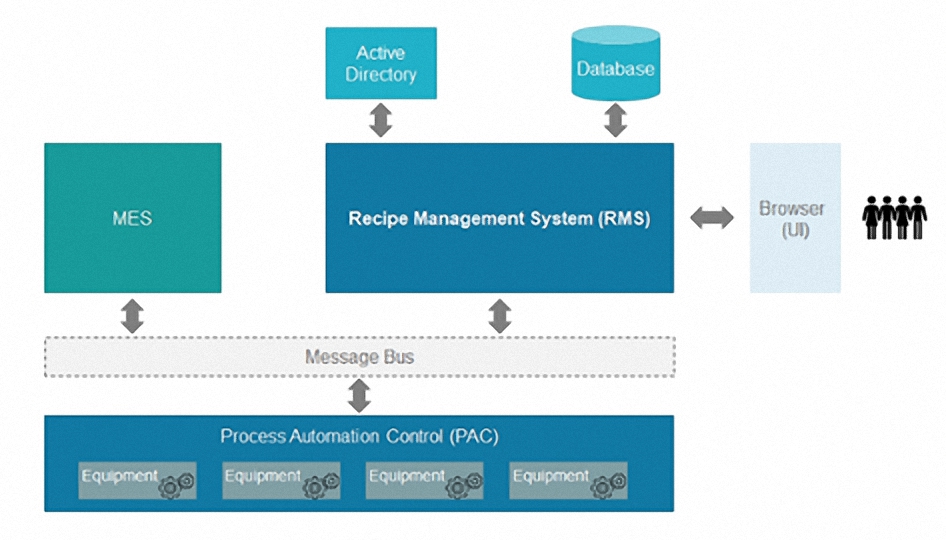

Recipe Management System works at the MOM level and has a web-based user interface that allows users to access it via a local account or an Active Directory. All data, including the recipe bodies, is stored centrally in a database. Integration with third-party systems is possible. Communication with the manufacturing machines is handled via a system integration platform such as PAC.

Core functions of Recipe Management System

Efficient recipe management for your production

Recipe management

Central database for recipe bodies and recipe parameters, templates and clear assignment of recipes to equipment

Upload & download of recipes

Provide production recipes locally or remotely to the equipment and upload new recipes from the equipment

Release process

Mapping of a release process to control the life cycle of production recipes

Recipe validation

Recipe bodies and recipe parameters can be validated using various methods, for example to ensure that the correct recipe is set on the equipment

Security & user-administration

Creation of local users or connection to an Active Directory for authentication and role-based access rights

Traceability

Reports on the traceability of recipe changes, approvals and users involved

Integration with equipment

Seamless integration with production equipment via interface-specific standard calls using an equipment integration platform (e.g. PAC)

Web based UI

Access to all functionalities via a web-based user interface with intelligent user support

By sitting at the Manufacturing Operations Management (MOM) layer and integrating seamlessly with Opcenter Execution Semiconductor (Opcenter EX SM) and your equipment-integration platform (PAC), RMS becomes the definitive repository, instantly distributing approved recipes to all machines and ensuring no unvalidated version ever makes it into production.