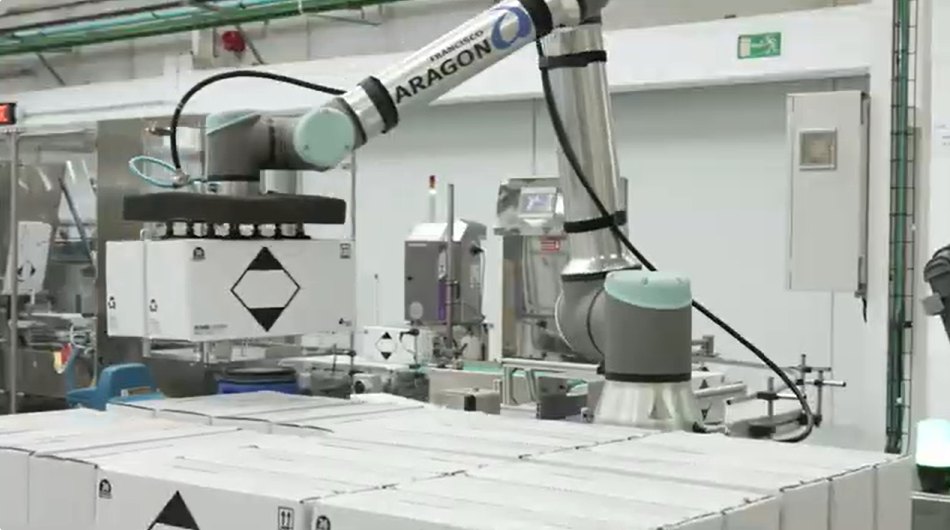

From Murcia to the world: how Francisco Aragon turned global expansion into a planning advantage

Francisco Aragon is a Spanish chemical company based in the Murcia region that specializes in ambient products you’ve likely encountered on supermarket shelves. Their portfolio—scented candles, fragrance sticks, insecticides, and aerosols—serves some of Spain’s largest retailers and market leaders. But the company’s reach extends far beyond Spain’s borders.

What began as a local Spanish operation has transformed into a genuinely global business. Today, Francisco Aragon produces for customers across Europe and is actively expanding into new markets: the USA, South America, and beyond. This isn’t just growth—it’s a fundamental shift in how the company operates.

But rapid global expansion comes with a hidden cost. As Francisco Aragon’s market footprint grew, their production planning system couldn’t keep pace. They were experiencing what Miguel Castro, the company’s CIO, describes as an “explosion” of complexity.

The company faced a critical question: How do you maintain operational control while scaling globally? This is the story of how Francisco Aragon answered that question by transforming their production planning process with Siemens Opcenter APS—and achieved remarkable results in the process.

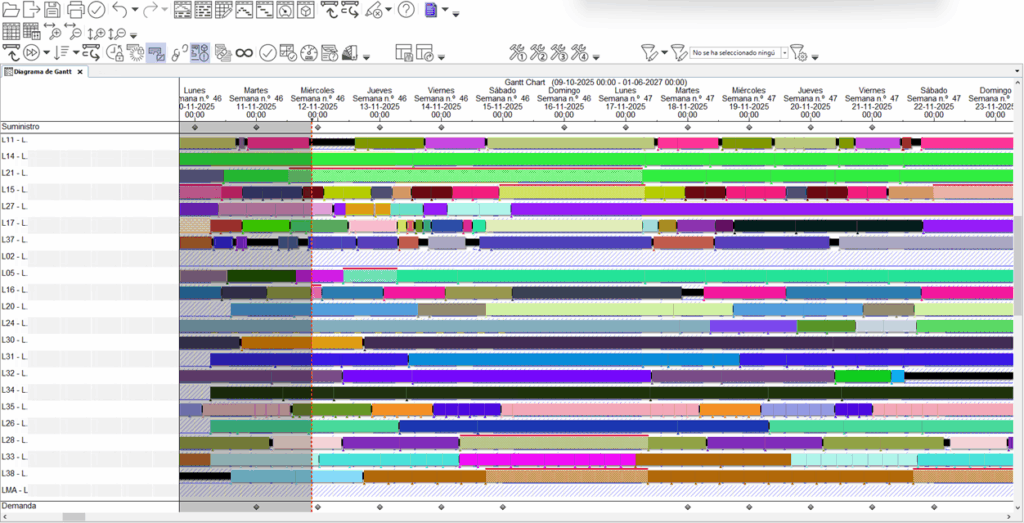

Gaining visibility and control across 35 production lines

To understand the complexity of their business, consider this: Francisco Aragon operates two production plants in Spain with more than 35 specialized production lines and manages over 1,000 different SKUs (stock-keeping units). Each production line is specifically designed for particular product topologies, creating a highly constrained and intricate manufacturing environment.

As Francisco Aragon transitioned from a local business model to a global one, they faced mounting operational pressures:

Rapid Complexity Growth: The company wasn’t just growing. Expanding from Spain to Europe, the USA, and South America meant managing increasingly diverse customer demands, supply chains, and market conditions.

Business Model Transformation: Traditionally, Francisco Aragon operated on a make-to-stock model. However, as they pursued new customers and markets, they needed to shift toward a make-to-order strategy. This fundamental change required a completely different approach to production planning and scheduling.

Unstable Production Schedules: Before implementing Opcenter APS, Francisco Aragon struggled with extremely short frozen periods—just 2-4 days. This meant: constant changes to production schedules throughout the day, reduced efficiency on the production floor, stress on employees who had to adapt to continuous modifications and – overall – limited visibility into future production needs.

Watch the full interview to see how Francisco Aragon transformed their operations with Opcenter APS.

Video interview by Miguel Castro, Francisco Aragon, CIO

Building a planning system that could scale with them

When Miguel Castro and the Francisco Aragon team evaluated solutions, they recognized that they needed more than just incremental improvements—they needed a tool that could help them “think out of the box” and handle the complexity of their expanding global business.

The Strategic Fit

Siemens Opcenter APS emerged as the ideal solution because it offered:

- Advanced Planning Capabilities: The ability to handle complex manufacturing constraints across 35+ production lines with thousands of SKUs

- Scalability: A platform designed to grow with their business as they expanded into new markets

- Integrated Approach: A tool that could integrate seamlessly into their existing planning processes

- Ecosystem Potential: Part of the broader Siemens Digital Industries ecosystem, offering a pathway for future digital transformation initiatives

As Miguel Castro noted, they were particularly drawn to the opportunities within the Siemens ecosystem and the potential to integrate multiple technologies to create a comprehensive digital transformation strategy.

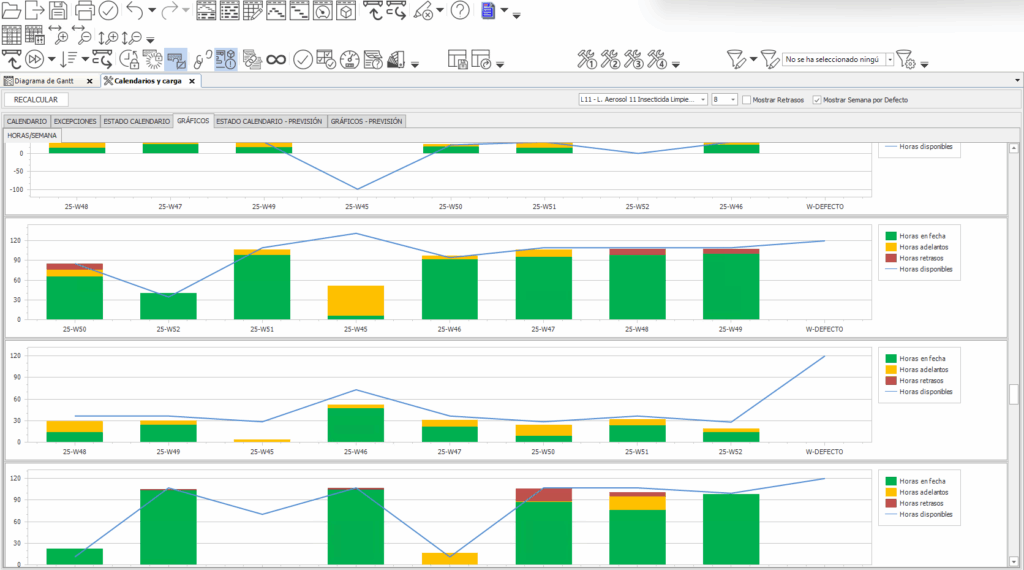

Unlocking stability and agility: three key transformations

The impact of Opcenter APS on Francisco Aragon’s operations has been substantial. Miguel Castro highlighted three key performance indicators (KPIs) that demonstrate the value of the solution:

Dramatically Improved Order Adherence

- Before: 65-75% order adherence

- After: 85-90% order adherence

- Impact: A significant improvement in the company’s ability to meet production schedules and customer commitments

Extended Frozen Period for Stability

- Before: 2-4 days

- After: 12-15 days

- Impact: The extended frozen period means fewer daily schedule changes, improved production efficiency, reduced worker stress, and a more seamless, established workflow on the production floor

Enhanced Long-Term Visibility

- Achievement: 12+2 months of visibility (over one year into the future)

- Impact: The ability to plan not just for the short term but for the mid and long term, allowing Francisco Aragon to anticipate market fluctuations, prepare for material deliveries, prevent unexpected supply chain disruptions and make strategic decisions based on comprehensive data

Additional Benefits

Beyond these three KPIs, Francisco Aragon gained:

- Reduced Complexity: Better management of their intricate manufacturing environment

- Increased Agility: The ability to respond to market changes while maintaining operational stability

- Improved Efficiency: Streamlined planning and scheduling processes

- Better Decision-Making: Data-driven insights for production and strategic planning

A commitment to sustainability

Notably, Francisco Aragon’s digital transformation journey extends beyond operational efficiency. Miguel Castro emphasized that the company wanted to “make a difference not only from the point of view of efficiency but also from the point of view of sustainability.”

This commitment integrates chemistry, engineering, and material science—reflecting a holistic approach to modern manufacturing that balances profitability with environmental responsibility.

Looking forward: the digital transformation continues

The success with Opcenter APS has energized Francisco Aragon’s broader digital strategy. The company is now exploring additional Siemens solutions, including:

- Mendix: For low-code application development

- Teamcenter: To address one of their main gaps—the disconnection between various tools and information silos—and to create a unified platform for managing all processes

As Miguel Castro explained, the vision is to integrate all different technologies under “the same umbrella or the same paradigm of information integration and process integration,” creating a cohesive digital ecosystem that drives efficiency and innovation.

Conclusion

Francisco Aragon’s journey with Siemens Opcenter APS demonstrates how the right technology partner and solution can transform a manufacturing company facing rapid growth and increasing complexity. By improving order adherence, extending planning horizons, and reducing operational chaos, Opcenter APS has enabled Francisco Aragon to scale confidently while maintaining the operational excellence their customers expect.

As they continue to expand globally and explore additional Siemens solutions, Francisco Aragon stands as a compelling example of how digital transformation—done thoughtfully and strategically—can drive both business success and sustainability.

About the Expert

Miguel Castro is the CIO of Francisco Aragon, where he oversees the company’s digital transformation strategy, integrating data, processes, and information systems to drive efficiency and innovation across the organization.

Ready to transform your production planning?

Discover how Siemens Opcenter APS can help your organization achieve similar results.