Video: NX 11 for Manufacturing Overview

New manufacturing software technologies in NX 11 for Manufacturing can dramatically improve productivity and create new opportunities to transform your business. The robotics machining and groundbreaking hybrid additive manufacturing capabilities let you produce completely new parts with better performance, while delivering tremendous savings. With Line Designer’s point cloud updates you can design and visualize layouts of production lines more quickly and associate the production layout design to manufacturing planning. New advanced NC programing capabilities for molds and dies, prismatic components, and complex-geometry parts enable efficient programing, while reducing machining cycle and improving parts’ quality.The complete video transcript is below.

Watch this video about the new capabilities of NX 11 for Manufacturing.

Video transcript:

NX for Manufacturing – Digitalize your machine shop

-

- Transform your production with new, innovative technologies.

-

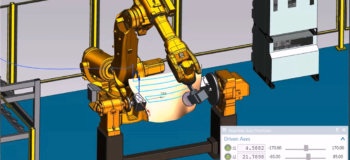

- Expand manufacturing automation with robotic machining.

-

- Design accurate production layouts using scanned cloud data.

NX CAM: 1) Program 60 percent faster with the latest hole making methods; 2) Machine high quality molds using optimized methods for each region; 3) Visualize cutting parameters of complex 5-axis operations.; 4) Create associative work instructions for the shop floor.

NX CMM Inspection Programming: 1) Inspect parts three times faster with head touches; 2) Visualize inspection results on the 3D model.

NX Tooling Design: 1) Easily manage mold/die bills of material; 2) Re-use library components to speed up tooling design.