The Future of Part Manufacturing: Siemens Industrial-Grade AI Featured in Modern Machine Shop

Industrial-grade AI is quickly becoming a cornerstone of the future of part manufacturing — driving smarter CNC programming, predictive quality, and data-driven decision-making on the shop floor. Recognizing this shift, Modern Machine Shop, a leading trade publication serving the global machining and digital manufacturing community, recently featured insights from Rahul Garg, Vice President for Industrial Machinery at Siemens Digital Industries Software, in an article titled “Enhancing the Shop Floor with AI.”

In the feature, Garg explains how AI and digital twins can act as a force multiplier, optimizing processes and empowering engineers without replacing their expertise. By spotlighting Siemens approach, Modern Machine Shop underscores the critical role industrial-grade AI will play in shaping the next generation of resilient, efficient, and sustainable manufacturing.

Rahul Garg

Vice President for Industrial Machinery

Siemens Digital Industries Software

AI as a force multiplier

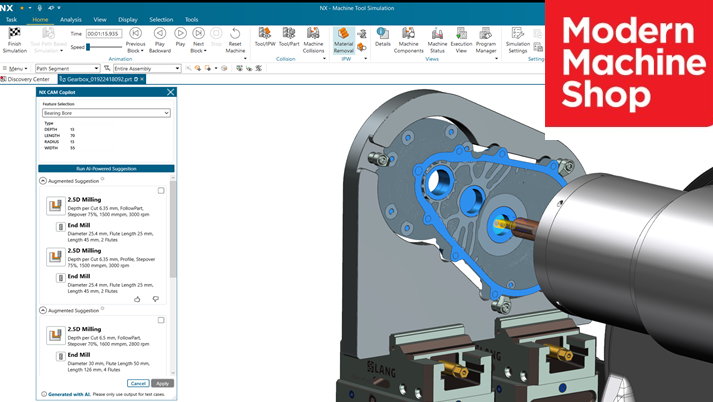

In the article, Garg makes it clear that AI in manufacturing is not about replacing people but about empowering them. By acting as a force multiplier, AI copilots can help engineers and machinists save significant time while improving accuracy and efficiency. For example, within NX CAM, AI can automatically suggest toolpaths, validate machining strategies, and reduce programming time by up to 80%. These tools ensure that experts spend less time on repetitive tasks and more time on innovation.

The need for industrial-grade AI

Garg stresses that in manufacturing, where even the smallest error can mean costly rework or compromised safety, AI must be industrial grade — robust, reliable, and built with human oversight. Unlike consumer AI, industrial AI includes continuous testing frameworks, built-in validation, and safeguards that keep people in the loop for critical decisions. This standard ensures that shops can trust AI recommendations for production while maintaining the highest levels of quality.

Unlocking new efficiencies in part manufacturing

The article also highlights practical ways Siemens’ AI is being applied today:

- Predictive quality that catches defects early by analyzing sensor data such as vibration or acoustic emissions.

- Energy optimization to monitor and reduce resource consumption.

- Ergonomic analysis through AI-driven human simulation, helping design healthier and more efficient workstations.

- Generative AI copilots that act as digital knowledge bases, capturing best practices and making expertise accessible to new employees.

By combining AI with the comprehensive digital twin, manufacturers can achieve faster workflows, better ergonomics, improved sustainability, and higher overall efficiency.

Building the future of data-driven manufacturing

For Garg, the future of manufacturing lies in using AI to analyze, optimize, and generate improvements across the shop floor. As he explains, data is the lifeblood of modern industry, but without AI, much of its value goes untapped. Siemens’ AI-driven solutions like Insights Hub Production Copilot are already helping manufacturers uncover root causes of issues, streamline operations, and guide operators with actionable insights.

The message is clear: with AI copilots and industrial-grade digital tools, manufacturers can bridge the gap between people, machines, and data—paving the way for smarter, more resilient operations.