Siemens at Hannover Messe 2025: Digital Manufacturing at the Forefront with AI, Digital Twin, and Cloud Technologies

Hannover Messe, set to take place from March 31st to April 4th, 2025, in Hannover, Germany, is the world’s premier industrial technology trade fair. The event gathers global industry leaders to present the future of manufacturing, automation, and energy.

Siemens continues to lead the way in innovation, driving next-generation technologies across diverse industries. At this year’s fair, Siemens Digital Manufacturing solutions will take center stage, featuring captivating exhibits, live demonstrations, and immersive hands-on experiences that provide a firsthand glimpse into the future of manufacturing.

Siemens Digital Manufacturing Next-Generation Technology Showcase at Hannover Messe 2025:

- Innovation Hub – Join live demos, deep-dive sessions, and exclusive keynotes from Siemens executives, covering the latest advancements in industrial AI, cloud technology, and the Industrial Metaverse.

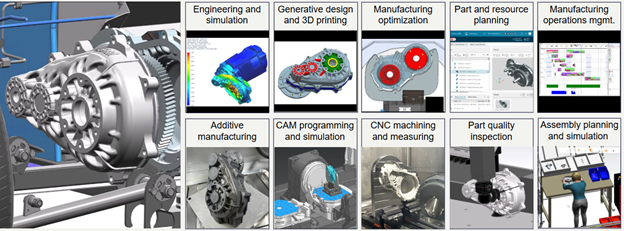

- Digital Part Production Showcase – Experience an end-to-end digitalization demonstration with cloud-based NX X Manufacturing and AI technologies. In the demo, immerse yourself in a design-to-manufacturing process for a high-performance part. See how we demonstrate the power of digital manufacturing by connecting every step of the digital thread, including design, 3D printing, CNC machining, quality inspection, and assembly.

- GenAI Copilot – Witness the power of Siemens latest advancements with artificial intelligence (AI) with the GenAI Copilot. See how AI is infused into Siemens solutions to improve your manufacturing productivity, decision-making and efficiency across multiple use cases.

- Pharma Industry Showcase – Explore how AI and Digital Twin technology are transforming pharmaceutical production, helping companies streamline formulation development, optimize processes, and deliver life-saving medicines faster.

- The Digital Thread Experience – Discover how Siemens solutions — Opcenter X, Industrial Edge, and Insights Hub— empower manufacturers to seamlessly integrate IT and OT data for smarter decision-making.

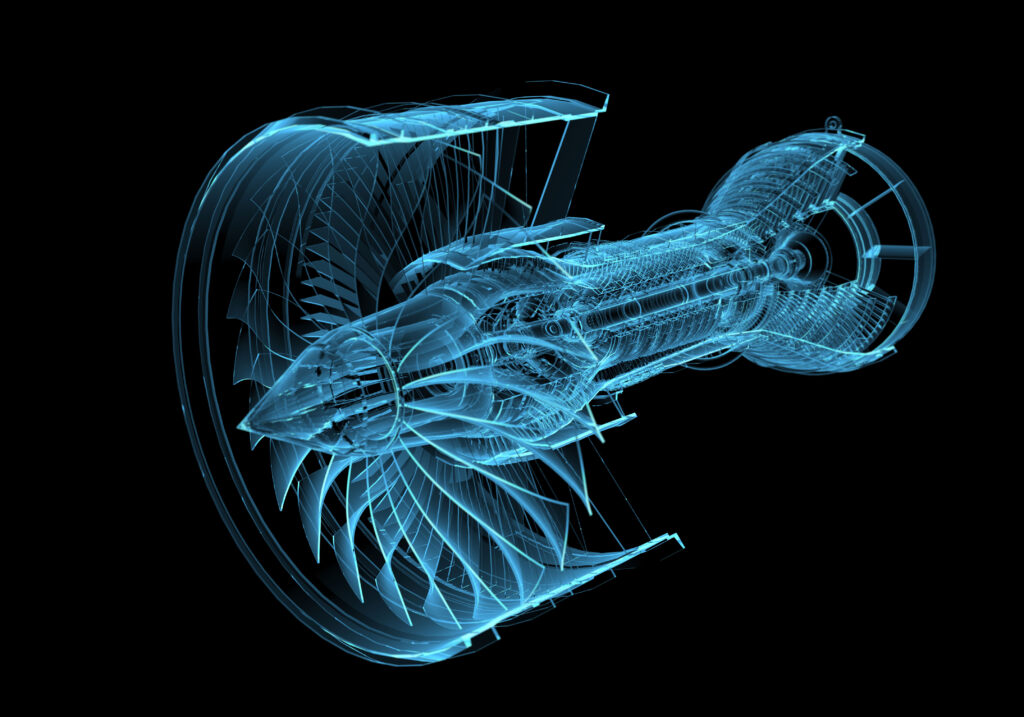

- Technology Partner Collaborations – Visit Siemens at the Microsoft booth (Hall 17, Stand G06) to see the AI-powered production of an innovative, re-imagined component of a Rolls-Royce jet engine – starting from initial requirements through design optimization to manufacturing.

- Siemens Digital Manufacturing stage – Join Siemens thought leaders as they share executive insights, from AI-driven optimization to sustainable supply chains, shaping the future of digital manufacturing.

Siemens Digital Manufacturing is leading the way with AI, cloud, and digital twin technology — all showcased at Hannover Messe 2025. Learn more below about where you can find Siemens Digital Manufacturing solutions.

Innovation Hub

In the Innovation Hub, we highlight innovation use cases featuring Industrial AI, Industrial Metaversie, Digital Twin and many more – enabled by our Siemens Xcelerator portfolio. Visitors can experience a variety of demonstrations that showcase how Siemens digital manufacturing software can help manufacturers design, realize and optimize products, and production.

Innovation Hub: seamless digital part production supercharged with AI

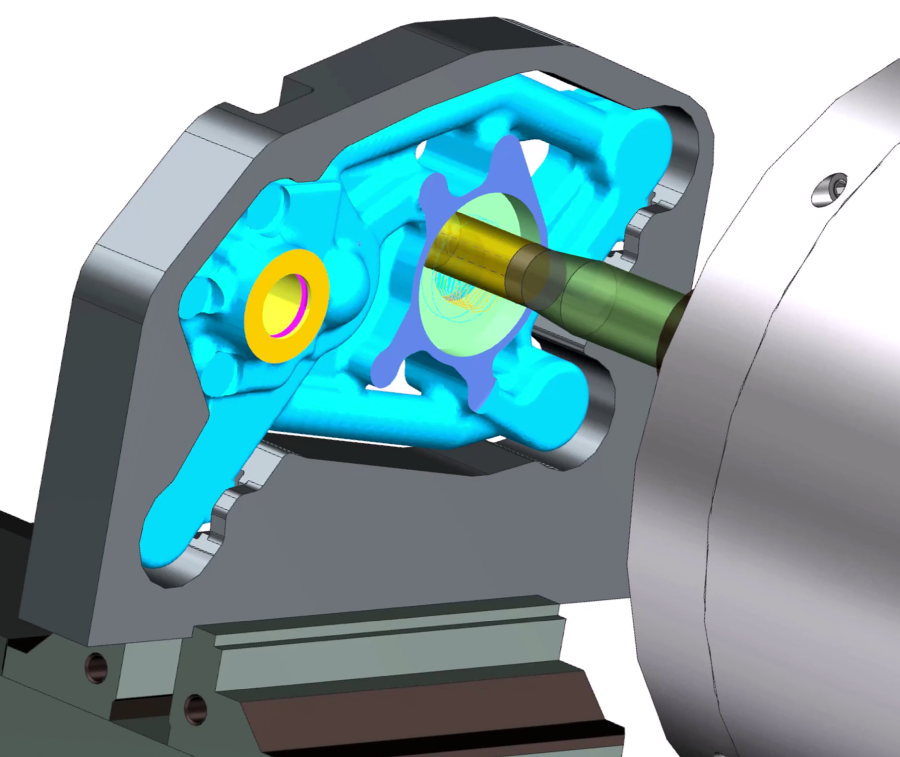

Experience an end-to-end digitalization demonstration for the next generation of components where we feature the design, simulation, manufacturing, and assembly of a reimaged, next-generation electric vehicle component. The end-to-end production process for an EV subassembly uses AI technologies powered by the cloud, generative design, 3D printing, CNC machining, and human simulation to make a higher performing transfer case for an electrical vehicle.

Learn how we designed and manufactured the transmission housing capable of withstanding high forces, reducing noise, and minimizing vibration. Imagine a future where CAM programmers no longer need to spend excessive time defining machining strategies as we demonstrate how AI technologies powered by the cloud, like NX X Manufacturing, provides recommendations on cutting strategies, tools, and toolpaths. The result? An EV part that is 35% stronger and 25% quieter than traditional designs.

Innovation Hub: AI enters the stage

At the Innovation Hub, you can also learn how Industrial AI enables companies to achieve significant improvements in various areas, such as enhancing product quality through automated quality inspections, reducing downtime with predictive maintenance, optimizing production efficiency by analyzing complex data patterns, and minimizing waste and inefficiencies in production processes.

Learn how Siemens GenAI Copilot integrates AI into various manufacturing solutions to boost efficiency, productivity, and decision-making, including:

- Easy Plan: Automatically extract data from multiple document formats and

convert unstructured text into standardized BOP format to validates standards, maintain version control and change history

- Process Simulate: Enhance robotic and human task simulations with AI-powered workflows, including a simulation and search query to pinpoint issues within complex robotic simulations without manual intervention, and AI-driven ergonomics to conduct advanced posture modelling with minimal time and effort.

- Insights Hub: Provides real-time analytics and actionable insights from across the shop floor, helping teams make data-driven decisions and improve operations.

- Quality: Automates defect detection and inspection, predicts quality issues before they occur, and provides real-time insights into quality performance. By continuously learning from production data, it ensures higher product quality, reduces costly errors, and identifies issues early in the process to improve overall efficiency.

- Teamcenter SLM (Service Lifecycle Management): Seamlessly integrate product data, service requirements, and service characteristics to create accurate, streamlined service plans and downstream components, driving enhanced service efficiency and excellence.

Even the most complex tasks in industries can be handled, with the help of both digital and physical agents, that can understand, plan and execute with minimal or no human intervention and aim to achieve specific goals through decision-making and adaptability.

Sustainable Digital Enterprise in Pharmaceuticals and Life Sciences

In the pharmaceutical and life sciences sectors, reducing the time from lab to patient is crucial. Visit this industry vertical showcase at Hannover to witness an end-to-end solution along the entire lifecycle to speed up development time, run production more efficiently, flexibly and sustainability.

The showcase demonstrates how Digital Twin technology streamlines formulation development, reduces operational costs, and optimizes resource utilization, ensuring medicines and therapeutics reach patients faster than ever before.

ERM/Tech Transfer

As part of the pharmaceutical booth, explore the Enterprise Recipe Management (ERM) tech transfer stage where you can learn more about the digital backbone of data-driven knowledge sharing. Specifically, learn how to streamline and accelerate the transfer of the recipe to production and enable knowledge-driven recipe transformation.

Smart Manufacturing

After visiting the ERM stage, stop by Pharmaceutical Smart Manufacturing booth where we show you how to speed up the engineering of the process and the plant to enable continuous production. Learn how manufacturers, like you, can accelerate production without comprising quality by enabling automated, flexible, and continuous production in a demonstration. See how we integrate manual and automated processes and leverage AI for fast batch record creation.

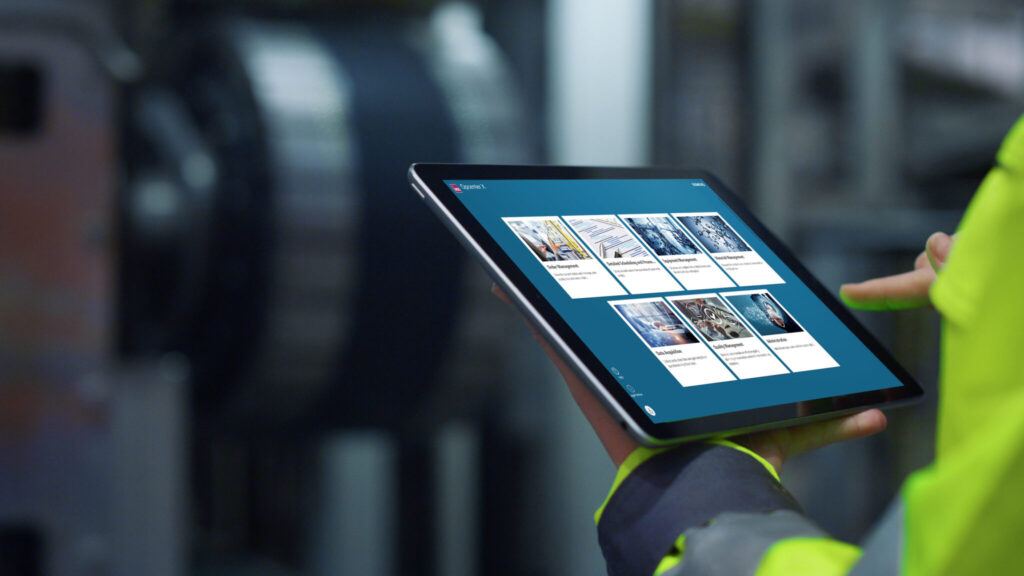

The Digital Thread Experience with Opcenter X, Industrial Edge and Insights Hub

The Siemens Digital Thread Experience presents real-world solutions to today’s industrial challenges, showcasing end-to-end digital thread powered by AI and cloud technologies. It spans critical areas such as Advanced Machine Engineering, Smart Manufacturing, Smart Product and Process Design, and Smart Infrastructure.

Join us to discover how Siemens solutions — Opcenter X, Industrial Edge, and Insights Hub— empower manufacturers to seamlessly integrate IT and OT data for smarter decision-making. Learn how Opcenter X, a cloud-based Manufacturing Operations Management (MOM) system, unifies scheduling, quality, and execution to boost productivity and reduce downtime.

Learn how Insights Hub transforms real-time data into actionable insights, while Industrial Edge ensures seamless connectivity in brownfield environments. Whether you’re looking to optimize production, accelerate NPI, or enhance operational agility, this session will show you how to take the next step in your digital transformation journey with Siemens.

Experience industrial innovation in action: Siemens joins Microsoft at Hannover Messe

Siemens is proud to collaborate with Microsoft to deliver powerful cloud-based manufacturing software through Microsoft’s cloud and AI platform Azure. Visit the Microsoft booth to witness how solutions such as NX X on Azure were used to help reimagine components for a new generation of products, such as an ultra-efficient aircraft displayed at the booth.

In this showcase, Siemens, Microsoft, and Rolls-Royce demonstrate how digital manufacturing enables companies to meet these objectives. See how the next-generation products, including the ultra-efficient aircraft, require enhanced performance, reduced weight, and greater sustainability. Conventional manufacturing methods may not always fulfill these demands.

Learn how an essential part for the aeronautics jet engine can be reimagined using Siemens cloud-based software, including AI-driven manufacturing CAM programming, generative design, 3D printing, and quality inspection. This unified end-to-end digital thread allows companies to innovate faster and manufacture next-gen products.

Visit Siemens at the Microsoft booth at Hall 17, booth G06. Learn more about the Siemens Microsoft partnership, visit: www.siemens.com/siemens-microsoft.

Digital Manufacturing on the Siemens Stage

Catch Siemens’ top thought leaders live at Hannover Messe as they share cutting-edge insights and real-world success stories shaping the future of digital manufacturing. From AI-driven optimization to sustainable supply chains, these sessions explore the latest innovations driving efficiency, productivity, and transformation. Watch live or catch the highlights later!

Here’s a glimpse of what’s in store:

- Reinventing Part Manufacturing

- AI-driven optimization for process and hybrid manufacturing with Easy Plan

- IT/OT integration: Scaling digitalization through seamless data connectivity

- Data-driven manufacturing: Turning operational insights into continuous improvement

- Insights Hub Production Copilot: Transforming data into actionable decisions

- Revolutionizing MES with Gen-AI: Accelerating recipe creation and deployment at scale

For the full stage program details, learn more here.

Don’t miss the future of digital manufacturing at Hannover 2025

Siemens Digital Manufacturing is at the cutting edge of innovation, paving the way for the future with AI, cloud, and digital twin technology and more — all set to be showcased at Hannover Messe 2025. This is more than just a showcase; it’s a glimpse into the future of manufacturing, where intelligent systems, real-time insights, and seamless integration are accelerating efficiency and productivity faster than ever before.

Whether you’re interested in exploring the latest in industrial technology or seeking collaborative opportunities, Siemens’ exhibits at Hannover Messe 2025 offer a glimpse into the future of industry. Don’t miss this exciting opportunity —join us in-person or virtually to experience how we are shaping the next era of digital manufacturing.