EMO 2017 – Digitalization in Machine Tool Manufacturing

EMO 2017 is right around the corner! We would like to invite you to visit us at the EMO Hanover 2017, September 18 – 25, in hall 25, booth D60.

Digitalization is set to be the defining theme once again at the EMO, the world’s biggest fair for the machine tool industry. Under the banner “Digitalization in Machine Tool Manufacturing,” Siemens will be demonstrating how machine tool users and manufacturers can benefit from digitalization with a presentation stretching over an area of around 1,200 square meters. Visitors to the booth can find out how Siemens is driving forward digitalization in the machine tool industry. The Siemens trade fair presentation will focus on the company’s extensive, integrated end-to-end digitalization portfolio. With this unique offering, Siemens will be showcasing ways in which machine tool manufacturers can significantly boost their production flexibility and efficiency, drastically reduce their engineering input and time to market, as well as consolidating and expanding their competitive standing in the global marketplace by digitalizing their operations.

Visit booth D60 to see Siemens new solutions to digitalize and transform part manufacturing.

Additive manufacturing reshapes everything

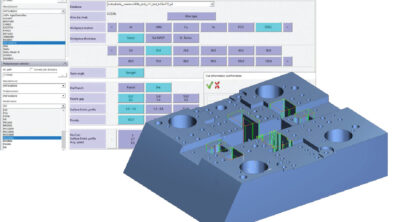

Siemens is driving the additive manufacturing revolution on several fronts. The NX product suite from Siemens PLM Software allows customers to reimagine designs like complex mold tooling.

A new capability called Convergent Modeling allows designers to utilize facet data from processes like topology optimization seamlessly with native computer-aided design (CAD) data. Unique tools such as Mold Wizard accelerate the design of molds for manufacturing. Integrated analysis tools can be used to simulate part performance and the NX CAM system can be used to prepare parts for printing and for connecting to printers for final manufacturing.

All of the tools necessary for execution of additive and subtractive manufacturing processes can be found within the same NX software system with no need for external utilities or data translations. Furthermore, the Simatic/Sinumerik controller platforms from Siemens power some of the most advanced additive manufacturing machines on the market. This combination of software and hardware from Siemens means that we are uniquely positioned to understand both sides of the additive manufacturing process.

Maximize robot productivity and flexibility with NX robotic machining

The use of robots is expanding rapidly in a variety of manufacturing industries. Beyond the familiar tasks of lifting, positioning and welding, today’s robots are being fitted with milling, grinding and other heads so they can be used to deburr, grind, cut, trim, polish, linish, glue and more. These tasks require the robots to perform continuous precision motions, including area coverage patterns and removal of in-process material. It can be challenging to program this type of motion for robots using a manual approach.

Siemens PLM Software has integrated its proven Tecnomatix® software for advanced robotic solutions with NX CAM software to offer the NX CAM Robotics Machining solution. This makes it easy to program a robot to cut, trim, linish, etc., using familiar NX CAM computer numerical control (CNC) programming methods.

NX CAM Robotics software lets you design, simulate, validate, optimize and offline program your industrial robots for machining-type tasks. This solution greatly increases the efficiency and quality of these high-precision, multi-axis robotic operations.

Navigate and master complexity using a smart map of the shop floor

Tecnomatix Intosite software is a cloud-based web application that makes digital manufacturing and production information accessible to a wider community in a simple and intuitive visualization environment. It fosters knowledge sharing and communication, and provides immediate and hassle-free access to information.

Available data items are displayed with a flag on their associated machines or stations in the factory visuals. These information items can be pulled from almost any database, including MRP, ERP, Teamcenter, and even real time from your machine controllers using MindSphere applications.

Shop personnel and managers can contribute additional information directly to the Intosite system in the discussion panel, helping to speed up resolution of issues as they arise. Everyone has access to the relevant data and communication is preserved for all the parties to review, even through shift changes.

For more information about our presence at EMO, read the press release, “Siemens demonstrates concrete potential of digitalization for the machine tool world“