Digital Manufacturing in Focus: Realize LIVE Asia-Pacific 2025 Recap

Realize LIVE Asia-Pacific 2025 made its debut in India, taking place in Bengaluru for the first time. With India emerging as one of the fastest-growing markets and a hub for global engineering and manufacturing centers, it offered an ideal platform for innovators and decision-makers shaping the future of digital manufacturing.

The event brought together over 1,500 attendees, including 879 customers, supported by 116 speakers, 95 sessions, and 19 sponsors and partners. Participants explored how Siemens software solutions are helping companies accelerate their journey toward becoming fully connected digital enterprises.

Digital Manufacturing as center stage

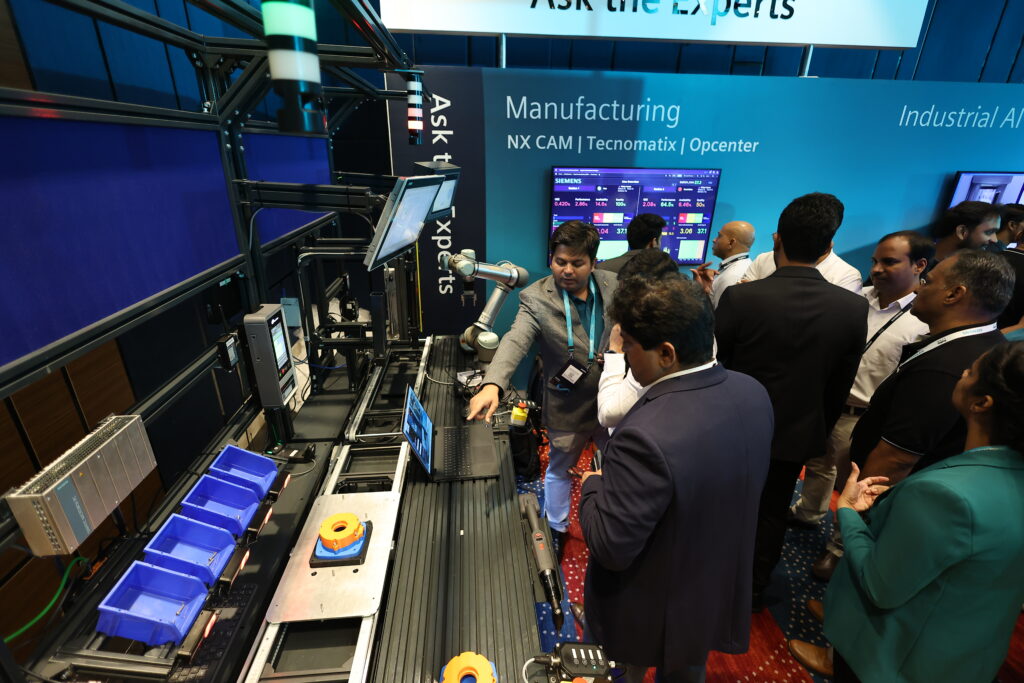

This year, digital manufacturing took center stage, with sessions, customer stories, and live demonstrations showing how companies are transforming operations with Siemens software solutions. From sessions featuring solutions like NX CAM with latest capabilities for part manufacturing and CAM programming, Tecnomatix with virtual commissioning, line planning, and human-centered simulation, Teamcenter Manufacturing and Easy Plan with connected process planning for ETO, BTO, and CTO operations, Opcenter with quality and production management, and Service Lifecycle Management with product service readiness, attendees got a comprehensive view of how Siemens’ digital manufacturing solutions drives efficiency, collaboration, and smarter operations.

Sessions exploring artificial intelligence, the industrial metaverse, sustainability, and IIoT showcased how these trends are driving innovation and shaping the future of digital manufacturing.

Keynotes from Thought Leaders

Realize LIVE Asia-Pacific opened with thought-provoking keynotes that set the tone for the event. Tony Hemmelgarn, President and CEO of Siemens Digital Industries Software, discussed how leading organizations are turning complexity into a strategic advantage. He highlighted the role of integrated systems and the comprehensive digital twin in driving innovation through AI, lifecycle intelligence, and adaptive production. Companies across industries are becoming digital enterprises—streamlining operations, improving agility, and creating new opportunities for growth.

Joe Bohman, Executive Vice President of Siemens Digital Industries Software, followed with a forward-looking keynote on what’s next for Siemens software. He showcased how AI-driven enhancements across existing solutions are boosting speed, productivity, and innovation. He highlighted the four digital threads: accelerated product development, software-defined products, integrated BOM management, and smart manufacturing, giving attendees a clear perspective on the roadmap shaping the future of design, manufacturing, and delivery.

Digital Manufacturing Sessions in Action

Digital manufacturing was a major focus at Realize LIVE Asia-Pacific, with nearly one-third of sessions showcasing how Siemens solutions help companies transform operations.

NX for manufacturing

NX for Manufacturing session showcased the latest in part manufacturing. Armin Gruenewald, VP of Part Manufacturing Business Line at Siemens DISW, led a session on today’s challenges in part manufacturing, highlighting innovations such as cloud-based NX X Manufacturing, AI-driven CAM programming, digital twins, and the newest NX CAM capabilities. Sansera Engineering, a leading component manufacturer, also shared its journey from legacy systems to Teamcenter, demonstrating measurable improvements in efficiency, integration, and scalability.

Tecnomatix

Tecnomatix sessions highlighted virtual commissioning, line planning, and human-centered simulation, showing how manufacturers can validate production processes, optimize workflows, and enhance operator safety before physical deployment.

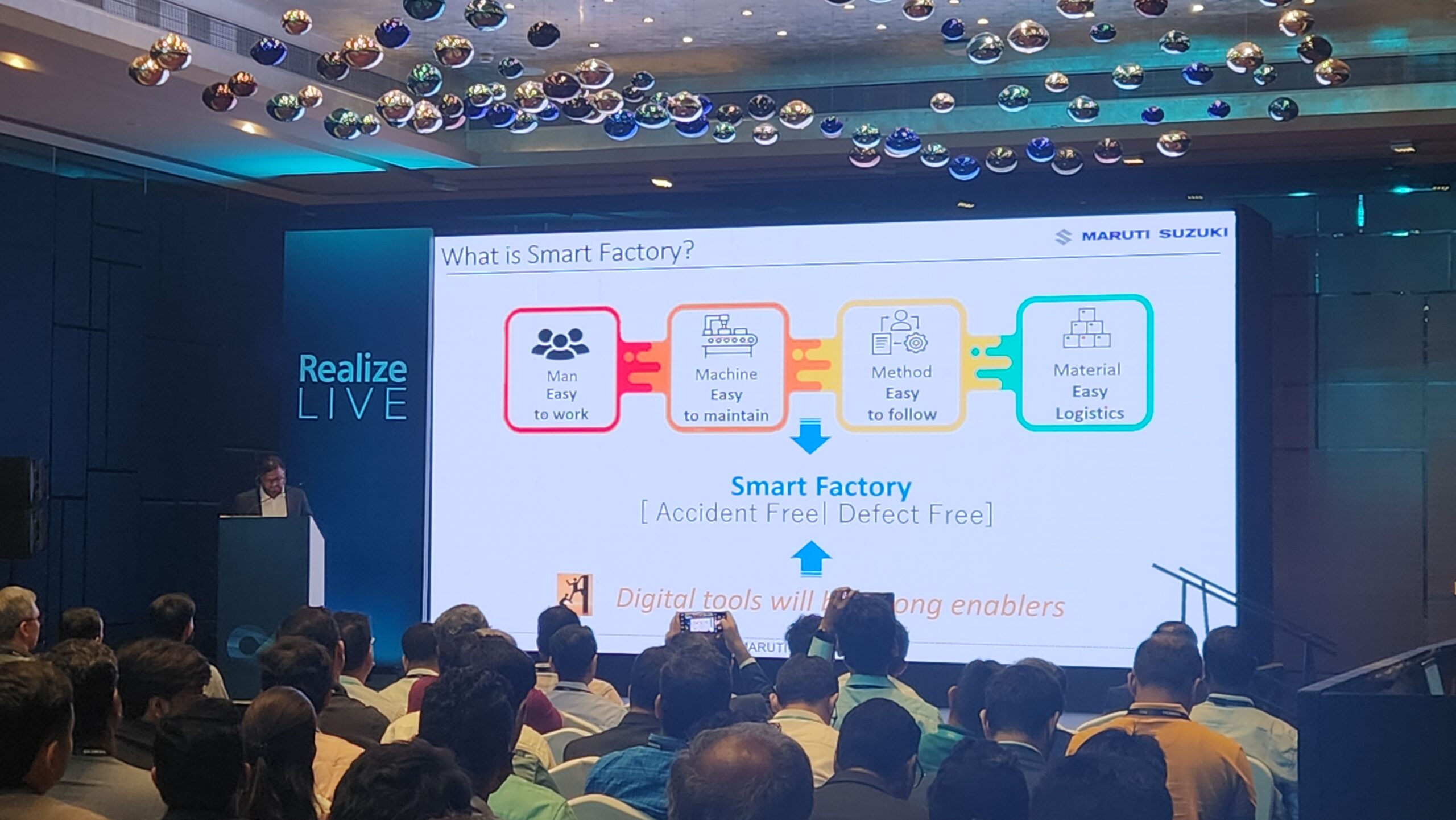

- Maruti Suzuki India Limited, a leading automotive OEM discussed strategies driving streamlined operations and business growth.

- Caterpillar, a global leader in construction and mining equipment demonstrated human simulation techniques that enable “first-time-right” product launches, reducing rework and improving performance.

- Wipro PARI,a leading automation and robotics solutions provider showcased how digital twins and virtual commissioning accelerate production readiness and cut commissioning time.

Opcenter and Teamcenter Quality

Manufacturing Operations Management (MOM) continues to play a critical role in driving efficiency, quality, and visibility across production processes. At the event, MOM was also in focus, with the new SaaS solution Opcenter X recognized for lowering time and cost barriers through a modular, cloud-native approach. Sessions highlighted the Characteristic Digital Thread, enabling a closed-loop quality process—from defining critical features and planning inspections to feeding insights back to improve efficiency, visibility, and product quality.

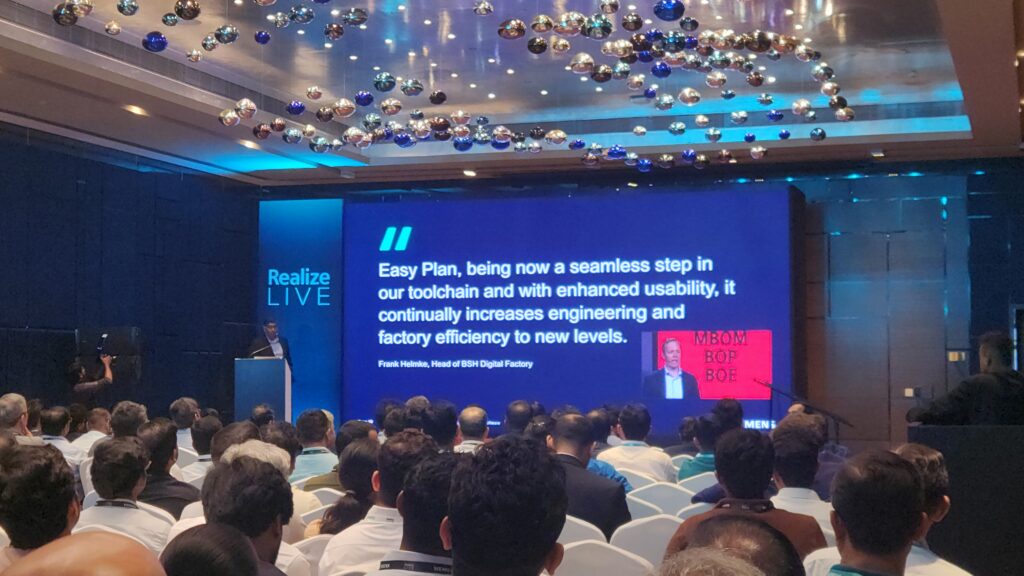

Teamcenter Manufacturing

Extending PLM into manufacturing is becoming increasingly critical for modern operations. At Realize LIVE, Teamcenter Manufacturing sessions showcased how this extension enables cross-functional collaboration, streamlining planning for ETO, BTO, and CTO models across global operations. Attendees also explored the Teamcenter Easy Plan roadmap and learned how it compares with legacy MPP solutions.

Service Lifecycle Management

Optimizing service throughout the product lifecycle is a growing priority for manufacturers. Sessions on Service Lifecycle Management highlighted strategies for balancing product- and service-led approaches, improving service readiness, reducing documentation effort, and maintaining quality standards. Product Support Data Management was showcased as a way to connect engineering and logistics information seamlessly across the product lifecycle.

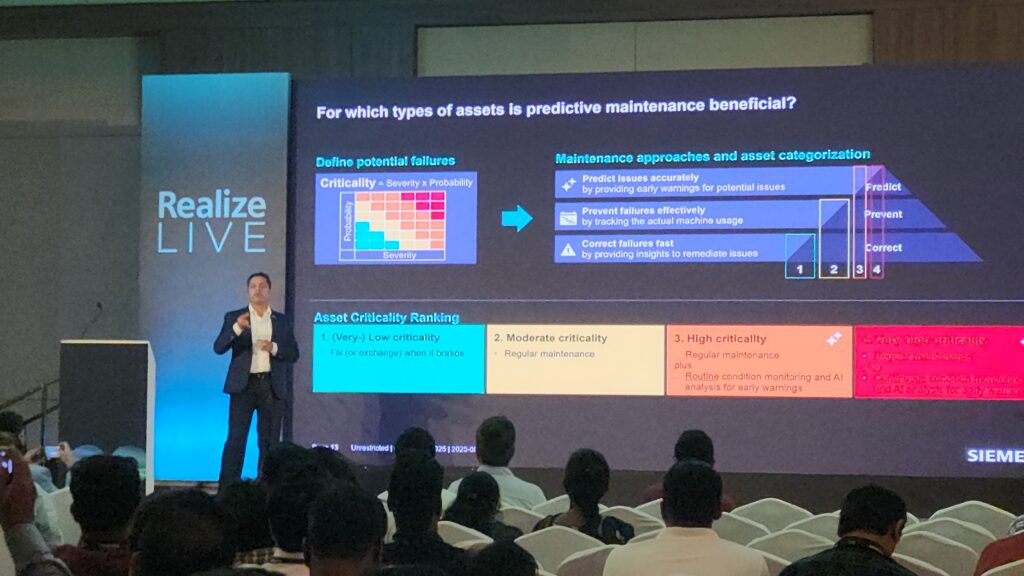

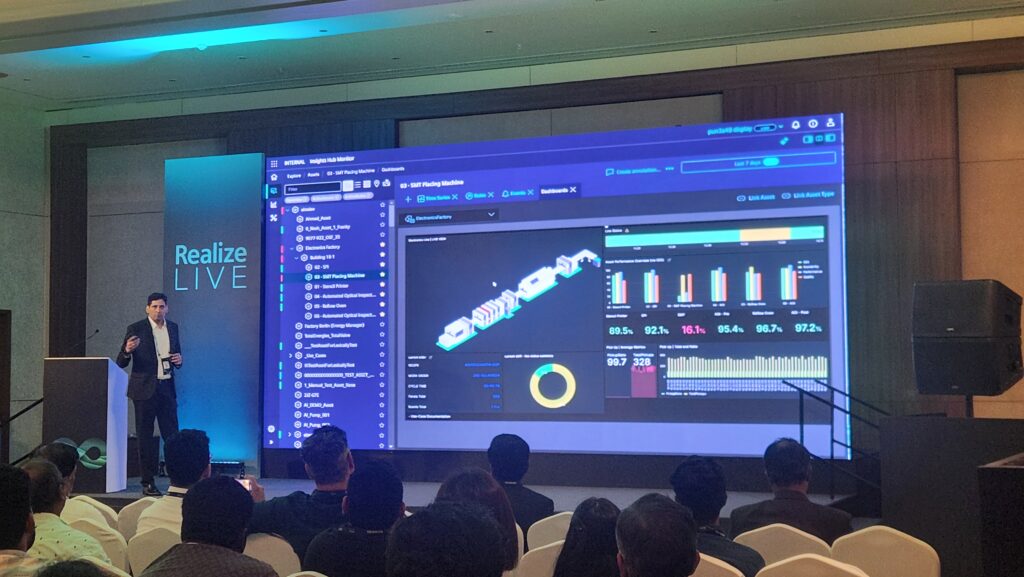

Insights Hub

AI-driven operational intelligence is transforming the way manufacturers manage assets. Insights Hub sessions demonstrated AI-powered predictive maintenance, delivering asset intelligence without manual analysis. Companies like Godavari Biorefineries showcased initiatives for transparency and sustainability. Tools such as Insights Hub Production Copilot combine machine data, context, and documentation to accelerate decision-making, support root-cause analysis, and drive continuous improvement.

Stay Connected and Keep Exploring

If you missed a session or want to revisit it, many Realize LIVE Asia-Pacific 2025 sessions are available on-demand. Catch up on the latest strategies, technologies, and customer stories shaping digital manufacturing.

The future of manufacturing is happening now, let’s keep building it together with Siemens digital manufacturing solutions.

Stay tuned for the on-demand content library from Realize LIVE Asia-Pacific 2025. In the meantime, check out the on-demand content libraries from Realize LIVE Americas and Realize LIVE Europe 2025.