By leveraging Line Designer, battery manufacturers achieve over 40% efficiency gains.

Revolutionizing efficiency in battery plant design

The rapid development of the new energy sector presents battery manufacturers with dual challenges: expanding production capacity while adapting to fast-evolving technology. Traditional 2D factory planning models no longer align with smart manufacturing requirements. However, Siemens Industrial Software’s innovative Line Designer solution is breaking new ground by leveraging 3D digital technology, redefining efficiency and accuracy in battery plant construction.

3D digital factory planning: A game-changer

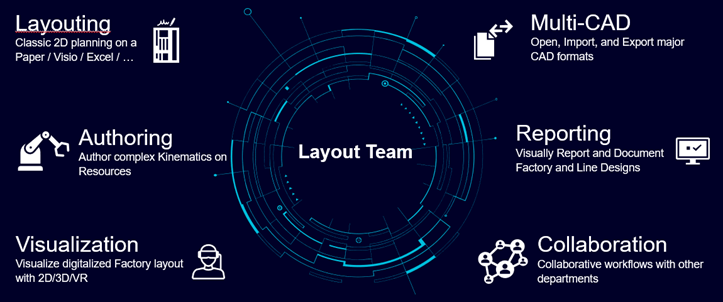

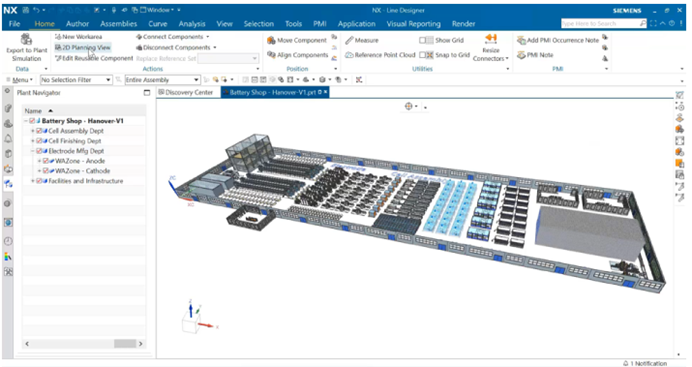

At the core of 3D digital factory planning is its full-process visualization and dynamic optimization capabilities. Siemens’ Line Designer utilizes parametric modeling technology, allowing engineers to seamlessly complete equipment layout, logistics path planning, data analysis, and report generation—all within a virtual environment. This advanced approach improves efficiency by over 40% compared to conventional 2D methods.

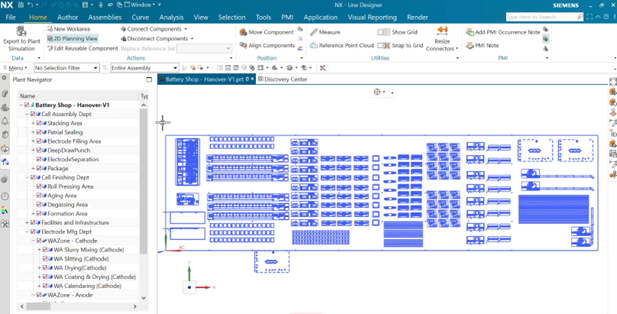

The system’s extensive intelligent library contains thousands of 3D models covering industrial equipment, building structures, and other key assets. It also supports multi-format data imports, including CAD and point clouds, making it ideal for complex renovation projects where flexibility and precision are critical.

Real-world impact: A 6GW super battery plant

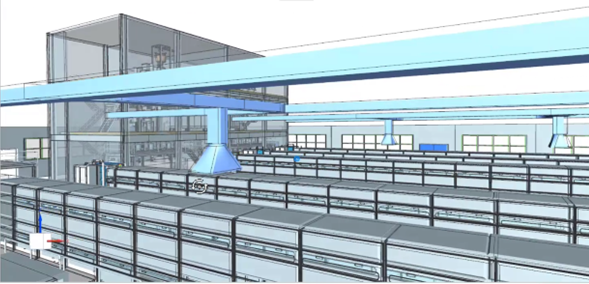

In a landmark 6GW battery manufacturing facility project, Siemens’ technical team harnessed Line Designer to achieve rapid, one-click conversion from 2D floor plans to 3D digital models. The software’s dynamic interference checking feature played a pivotal role in identifying and resolving spatial conflicts between production equipment and utility pipelines early in the design phase. This proactive approach significantly reduced potential rework costs, streamlining the overall construction process.

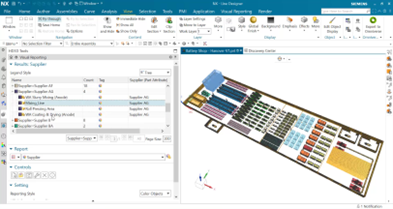

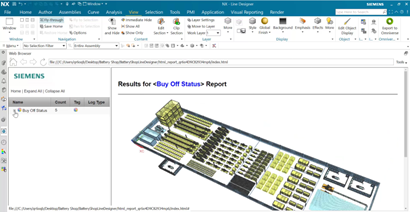

Moreover, Line Designer’s intelligent visualization system generates automated data dashboards that categorize information by supplier performance, equipment status, and other critical metrics. These insights empower procurement and engineering teams to make informed decisions, enhancing operational efficiency.

Streamlining Collaboration and Design Integrity

Engineers can rapidly complete 3D factory layouts by simply dragging pre-engineered models from the library onto 2D floor plans,” explained a project engineer using Line Designer. “The software also ensures seamless conversion of 3D models back into 2D blueprints through reference set switching, preserving full design integrity with a single click.”

A representative from Siemens Industrial Software further emphasized the transformative potential of this approach:

Our goal is to make factory planning as simple and efficient as building blocks. By integrating immersive interactive environments and kinematic simulation capabilities, customers can not only validate design plans intuitively but also pre-rehearse production processes in a virtual space, proactively mitigating potential risks.”

The future of smart manufacturing

As the new energy industry shifts toward intelligence and sustainability, 3D digital factory planning is emerging as an industry standard. Siemens Industrial Software remains at the forefront of this evolution, driving digital transformation in manufacturing through its deep expertise in industrial software solutions.

With cutting-edge tools like Line Designer, Siemens continues to enable manufacturers to optimize efficiency, reduce costs, and build smarter, future-ready factories. The 6GW super battery plant is just the beginning—ushering in a new era of intelligent industrial design and execution.

Benefits of Using Siemens NX Line Designer for Battery Plant Planning

Siemens NX Line Designer provides a transformative approach to battery plant planning through advanced 3D digital modeling. One of its key benefits is efficiency—engineers can achieve over 40% faster design completion compared to traditional 2D methods. The software’s parametric modeling capabilities enable seamless equipment layout, logistics path planning, and real-time data analysis within a virtual environment.

The tool’s intelligent library, containing thousands of pre-engineered 3D models, allows for accurate and rapid assembly of factory layouts. This feature supports multi-format data imports, including CAD and point clouds, making it particularly valuable for complex renovation projects. Additionally, the dynamic interference checking function proactively identifies and resolves spatial conflicts between equipment and infrastructure, significantly reducing costly rework during construction.

Another major advantage is enhanced collaboration. Engineers can convert 2D floor plans into fully functional 3D environments with a single click, facilitating seamless integration between different teams. The system also generates automated data dashboards, offering real-time insights into supplier performance and equipment status.

By integrating kinematic simulations and immersive virtual environments, Line Designer allows manufacturers to pre-rehearse production processes, minimizing risks and ensuring optimal factory performance. Siemens NX Line Designer ultimately enables smarter, more cost-effective, and future-ready battery plant construction.