Assembly Line Planner: Simplify complex planning tasks [VIDEO]

Guided planning and detailing for complex assembly tasks in an intuitive user experience

Assembly Line Planner is a process planning application based on Siemens NX™ software. It enables you to plan a complex production line with a focus on the different technologies and manufacturing features used to create an assembly, such as spot welds, weld studs, rivets, continuous joints for fastening and sealing, and more.

Throughout Assembly Line Planner (ALP), there is a constant focus on simplifying the complex planning tasks that users face, allowing the management of advanced workflows and PLM data to be accessible to everyone.

To achieve that goal, ALP guides you through the planning processes in a task-oriented view. That is, you are offered the exact data and commands required for each task in a dedicated view, allowing you to focus on what needs to be done at any point in the process.

Line planning

The planning process starts in the Line Planning view, where you distribute parts to stations and define the flow between stations in a modern PERT viewer. To better understand the distribution of parts, the assignment status of each part and assembly is displayed with an assignment indicator directly in the graphic viewer, identifying the parts based on their status. The visual buildup of the product in the assembly line can then be displayed as a result of this work.

Resource planning

When working on the plant layout, you can switch to the Resource Planning view, where you can access all the required layout functions while utilizing the embedded Teamcenter® software classification to access standard resources. In Resource Planning, the focus is on the plant itself while the product is temporarily blended out. This view offers many ways to define a rough layout or a detailed layout with exact measurements, leveraging utilities like connectors to quickly and easily position components within the plant.

Station detailing

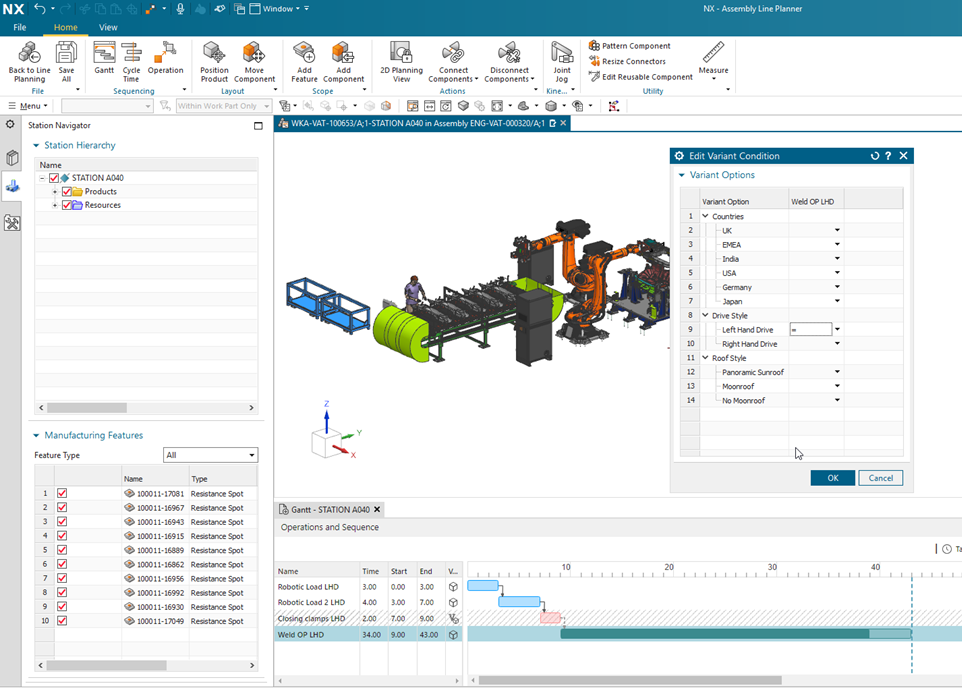

The Station Detailing view guides you through the process detailing inside of an assembly station. In this view, only the content of the station is displayed, including the equipment, the parts and sub-assemblies, and the manufacturing process required for that step in the assembly sequence. The parts and sub-assemblies are automatically positioned in the desired fixture in each station. Using an advanced feature search, you can identify which features need to be worked on and distribute them accordingly in custom operations. These features can then be classified and adapted based on the process that they represent. With the Gantt viewer available during station detailing, you can quickly recognize the different operation types creating the flow of the process in the station. In this view, you can also distribute features, parts and resources to the different operations and define operation variants.

By using Assembly Line Planner, you can leverage the advantages of a complex PLM system while working in an easy-to-use application that guides you through every step of the planning workflow. The various views for line planning, resource planning, and station detailing are optimized to support different tasks along this workflow.