ASM digitalizes production of electronics manufacturing equipment [VIDEO]

ASM Pacific Technology is the world’s largest supplier of semiconductor and LED manufacturing and assembly equipment. ASM specializes in providing this equipment for chip manufacturers, integrated circuit (IC) manufacturing factories, and consumer electronics manufacturers. As the industry leader, ASM places high value on product development and production of electronics manufacturing equipment.

Automating production of electronics manufacturing equipment

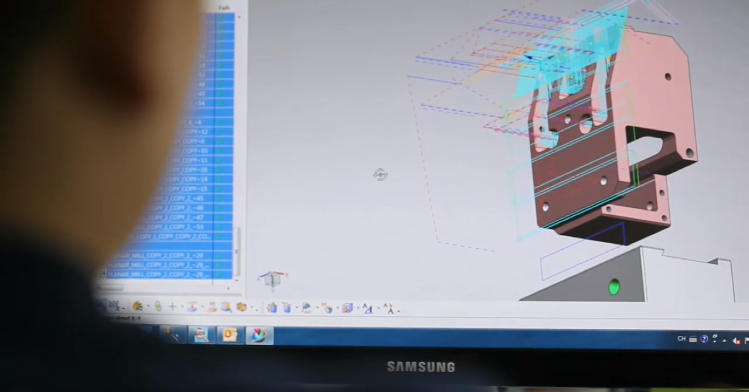

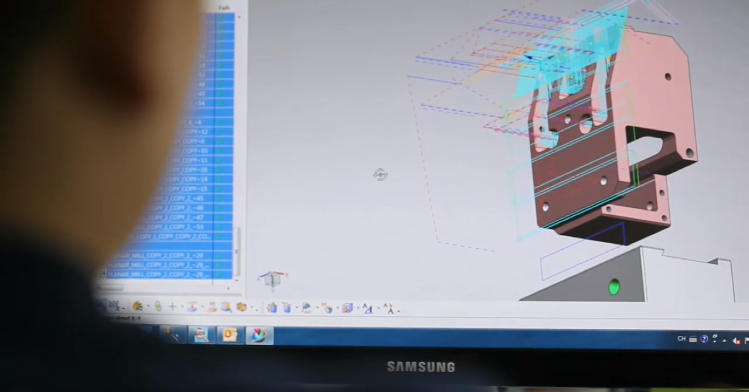

Because of the major time required to transfer design changes from product development to manufacturing, ASM realized it needed to integrate its CAD and CAM. In order to eliminate these connection problems, ASM now utilizes NX CAM as their parts machining software at the production/manufacturing stage.

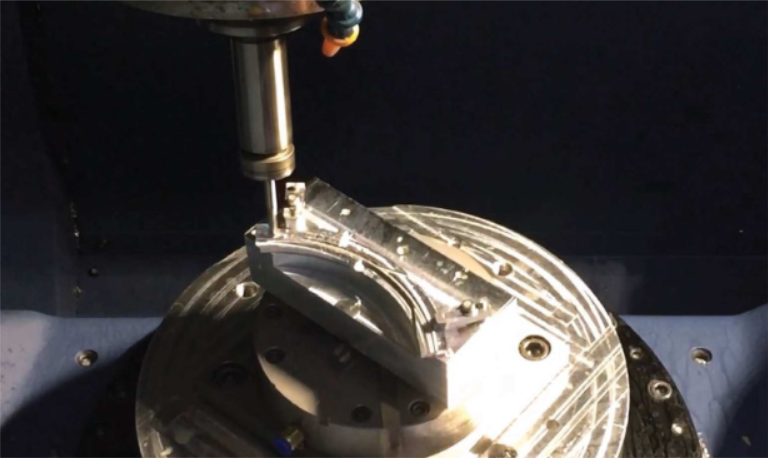

They immediately saw improvements, thanks to the feature-based machining (FBM) capability of NX CAM. With FBM technology, NX CAM can automatically read and identify PMI, including tolerances, surface machining precision, and other information attached to 3D product models. It allows for the automatic selection of machining methods, processes and tools while directly driving NC programming and machining. FMB also enables automatic transfer of related data between CAD and CAM, automatically identifying features and creating standardized NC programs for machining processes. With this, ASM can now minimize human error while maximizing productivity and accuracy.

The NX CAM integrated simulation and verification (ISV) capability significantly reduces programming errors and improves machining quality. With more advanced machining and manufacturing technologies, ASM is marching toward the goal of building smart factories.

Our statistical results show that feature-based machining and PMI have improved the producing efficiency and quality of ASM by 70 percent, thus saving a lot of valuable time.

Hu Dewen, Senior CAD/CAM Manufacturing Manager at ASM Pacific Technology