When AI becomes your CAM programming partner

Imagine this: You’re deep into programming a part in NX CAM. The 3D model is ready, the tool library is loaded, and everything seems straightforward. Then you need to program a complex pocket. Do you tackle this with a single endmill for both roughing and finishing to save a tool change? Or do you split the process between two specialized tools to optimize your material removal rates and surface finish?

Both choices are valid, and each has trade-offs. You pause, calculating whether the chip-to-chip time penalty of a tool swap negates the cycle time savings of a faster roughing pass. Minutes slip by. Multiply that hesitation across dozens of features a day, and it is easy to see where productivity is lost.

Now imagine a copilot seamlessly integrated into your workflow. It understands your geometry and features, instantly presenting strategies with recommended tools and parameters. You make the call, and programming moves forward effortlessly.

This is where AI becomes a true programming partner, helping you work smarter, reduce repetitive decisions, and focus on precision.

After all, who would not want to be a more productive CAM programmer focused on doing the work that matters rather than repetitive decisions?

How AI is Changing the Future of CAM Programming

For decades, CAM programming has relied heavily on experience. Every programmer builds an instinct for the right strategy for a surface finish, the correct feed rate for a tool, or when to adjust a cutting approach based on part geometry. Developing this expertise takes years, and even experienced professionals spend valuable time making decisions that could be automated.

Generative AI is great at understanding text, images, and video, but manufacturing data is nothing like that. It includes 3D CAD models, 2D drawings, bills of materials, dimensioning and tolerance, and historical operations. Gen AI cannot interpret this data meaningfully for machining purposes.

So, programmers end up switching between sources, relying on intuition, and checking with colleagues. And every decision matters. A tool that is slightly too short or a feed rate that is a bit too aggressive can lead to scrap or unexpected downtime.

This is where domain-trained AI shifts the conversation. It is built to understand how manufacturing works. It reads 3D models and geometries, interprets tolerances, looks at available tool libraries, and reasons with everything from BOMs to process notes to past simulations.

Instead of just recognizing shapes, it understands what the part is trying to achieve and what the machining setup allows. It can suggest realistic strategies that match material, tools, and shop best practices. In short, it takes the experience programmers have built over the years and makes it easier to apply consistently.

Today, AI in CAM software is taking shape in two main ways.

- The first is chat-based copilots integrated directly into the programming environment. They assist programmers by answering questions, explaining functions, and helping them navigate the software effectively.

- The other is through context- and geometry-aware machining intelligence. When a programmer selects a face or feature, the system provides AI-generated machining suggestions detailing operations, tools, and cutting parameters.

Together, these two approaches show where intelligent CAM programming is heading. It is not about replacing the programmer. It is about giving them tools that help them work faster, with more clarity, and with the confidence that every decision is backed by data and experience.

Moving toward smarter, context-aware programming

CAM programming is evolving toward smarter, context-aware assistance. Modern parts are increasingly complex, and manual programming can be slow and error-prone. Chat-based AI cannot interpret manufacturing data, and it cannot automatically recommend operations, tools, or parameters based on part geometry. To improve productivity, programmers benefit from AI that saves time and supports decision-making.

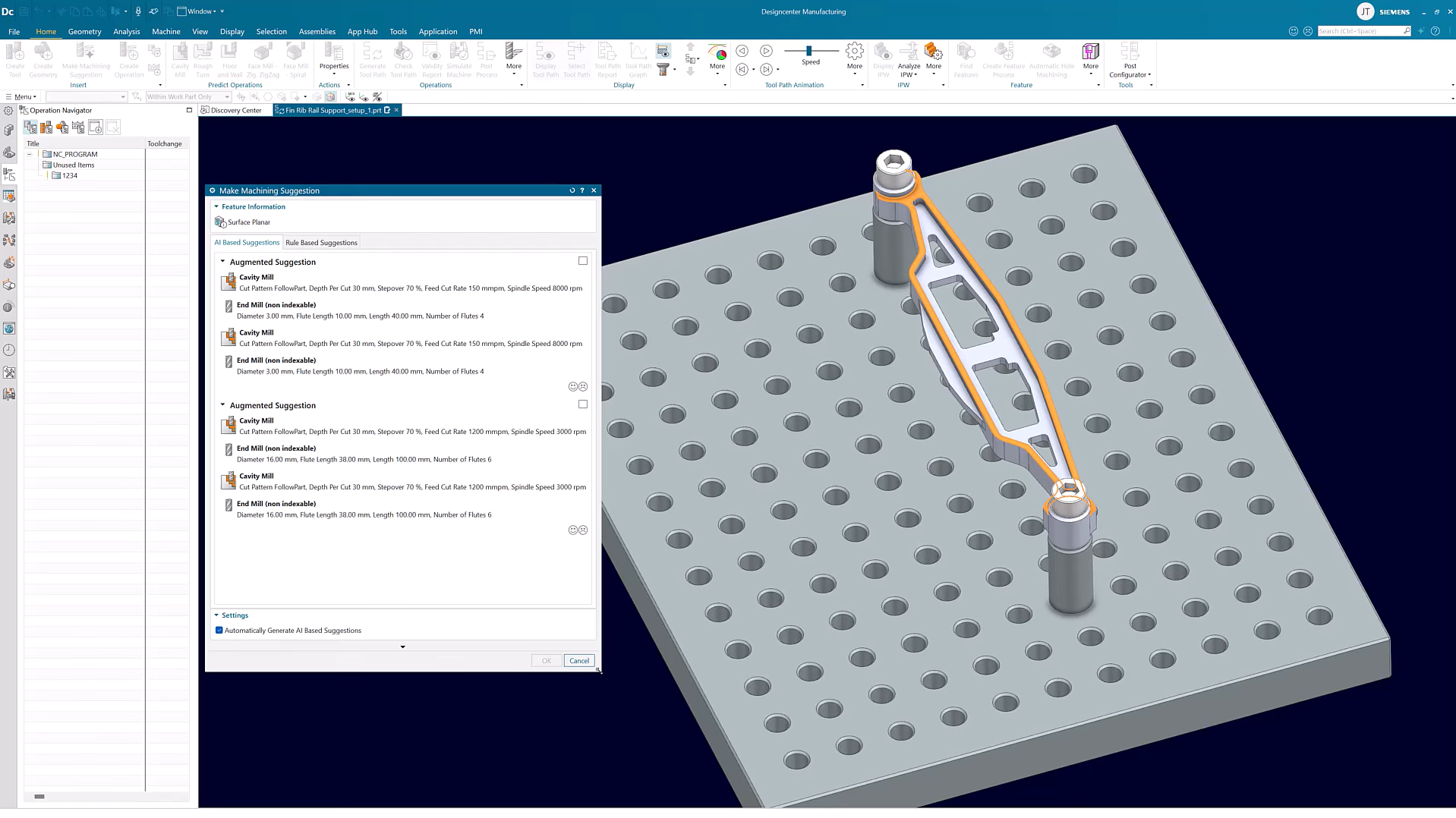

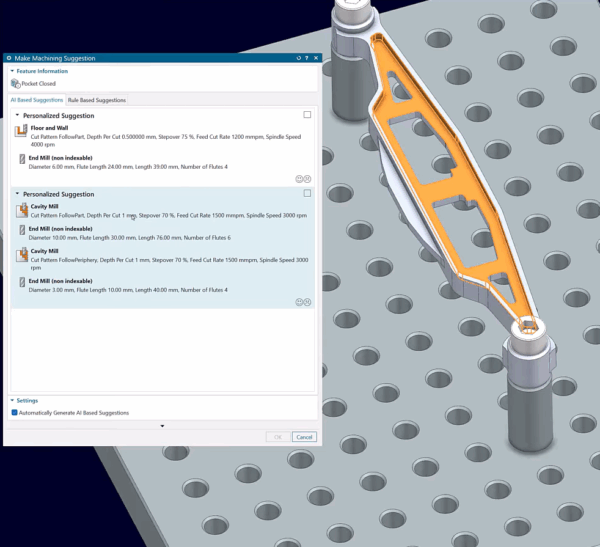

With NX X Manufacturing’s AI-powered Make Machining Suggestion (MMS), programming reaches the next level by:

- Recognizing faces and machining features

- Recommending multiple process operations and tool options

- Allowing programmers to evaluate and select the optimal approach

- Interpreting machining intent and considering context

- Providing actionable suggestions for faster, more accurate, and consistent CAM programming

- Enabling programmers to choose the best option based on the system’s recommendations

Watch the video to see how the AI feature works ⬇️

Imagine selecting a face or feature: the system evaluates it and presents machining approaches with operations, tools, and parameters already defined. Over time, as it learns from past work, suggestions align with familiar programming habits and shop standards. Tasks that once required multiple steps now happen in just a few clicks, keeping CAM programming consistent, efficient, and intuitive.

For example, when programming an M10 threaded hole, the system might suggest two valid approaches—tapping or threading—while leaving the final choice to the programmer. It then learns from these decisions and adapts guidance to match preferred methods or shopfloor practices, making each subsequent job faster and more precise.

When in doubt, let NX X Manufacturing Chat Copilot guide

Having context-aware guidance is one thing, but having a chatbot to help navigate complex CAM software and its many features is something else entirely—and it can make a real difference. Modern CAM systems are packed with capabilities, yet many of these features go unused because programmers simply don’t have time to stop, search, and relearn.

NX X Manufacturing Chat Copilot makes that easier. It lives inside NX CAM as a helpful companion, ready to answer questions, explain how functions work, or point you to the right documentation. It helps programmers discover features they might not have tried and reminds them how to perform common operations, like face milling, without breaking their workflow.

Ask something as specific as, “How do I change the non-cutting motion for a cavity mill operation” and the Copilot gives an instant, clear answer with supporting links. Natural language inputs will enable you to execute complex commands, enabling new users to navigate the software swiftly while boosting efficiency. Newer programmers gain confidence faster, while experienced programmers spend less time retracing steps.

NX X Manufacturing Chat Copilot streamlines everyday navigation inside NX CAM by answering domain-specific questions and pointing to relevant documentation. It helps programmers:

- Get guidance for the current feature or operation

- Navigate features or functions in NX they may not be familiar with

- Work effectively whether they are new or experienced users

- Keep programming efficiently and intuitively.

Watch the video to see how the AI feature in action ⬇️

The Next Chapter in Human-in-the-Loop Part Manufacturing

AI in part manufacturing is just getting started, but the direction is clear. It will increasingly connect design, simulation, process planning, and production in a seamless digital thread that creates a faster, smarter, and more connected way to work.

With modern AI-powered enhancements, Siemens is turning that vision into reality. By bringing together data, context, and human expertise, it keeps the human in the loop and ensures CAM programmers remain fully in control while AI assists in analyzing data, suggesting strategies, and streamlining programming tasks. Acting as a true partner, it helps programmers think faster, work smarter, and machine better.

The future of CAM programming isn’t about AI taking over; it’s about AI making every CAM programmer better. Together, they enable a new level of precision, efficiency, and confidence in every machining process.

Want to know how we are using AI to improve part manufacturing and CNC programming? Read the blogs to see it in action:

AI has arrived for CAM Programming: Smarter, Faster and Built for Industry [VIDEO]

Teaching AI to speak the language of Engineering and Manufacturing…

The Future of Part Manufacturing: Siemens Industrial-Grade AI…