Revolutionizing Remote Development of Personalized Arm Prosthetics for Kids

Easton LaChappelle was 14 years old when he decided to build a fully functional hand. Bored, curious and fascinated with robotics, LaChappelle decided that making a remotely controlled robotic hand would be a fitting challenge for his passions.

Eventually LaChappelle created a rudimentary robotic hand, but it wasn’t until his 16th birthday that he began advancing his design and setting the course for his unlikely future. That’s when he bought a cheap laser cut wood 3D printer and started running it 24/7. He improved the hand’s individual finger motion and its opposable thumb. Then he moved on to the forearm, elbow and shoulder until he had a complete arm. LaChappelle entered his robotic arm in several science fairs – and that’s when his fortunes took off.

LaChappelle started talking with the girl and her parents to find out how her prosthetic arm worked. What he learned both disheartened and inspired him.

“I found out that her prosthesis had cost $80,000, only had a pinching device and would soon be outgrown because it had taken a year to create. I thought, ‘this can’t be true; I built my arm for $300 in my bedroom.’ It was unacceptable to me. That was my aha moment.”

Easton LaChappelle, Founder and Chief Executive Officer

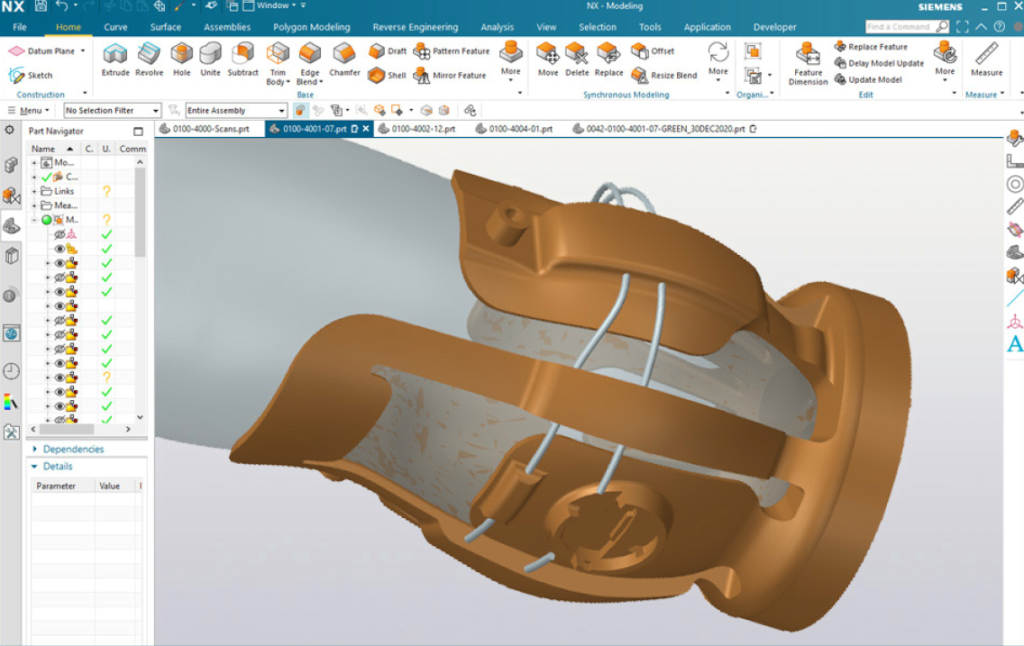

Fast forward to 2019, when Unlimited Tomorrow introduced TrueLimb, the industry’s first lightweight, affordable multi-articulating prosthetic limb with a realistic appearance. TrueLimb devices weigh 1.1 pounds, three pounds lighter than a typical pediatric prosthetic arm. They’re personalized for each user, right down to size, skin tone and fingernails. At $8,000, they’re drastically less expensive

than conventional alternatives. And perhaps most amazing of all, children can get TrueLimbs in weeks – without ever leaving the comfort of home. How has LaChappelle and his team managed to disrupt the prosthesis industry so dramatically and quickly? The answer is by bringing together a confluence of advanced technologies – remote 3D scanning, electronic sensing and additive manufacturing.

To learn more about Easton LaChappelle’s design journey and what Unlimited Tomorrow has been able to accomplish, click here.