What’s new in NX | June 2023 | Molded Part Design

Introducing Molded Part Design

Welcome! We’re excited to bring you the first episode of a new series, where we’ll be taking a deep-dive into brand new functionality added to the June 2023 release of NX™ software. The focus for this entry is Molded Part Designer – a brand new tool within NX. Take a look at the following video for more information. Or, if you prefer reading our content, read on below 👇

What is Molded Part Designer?

Molded Part design brings design validation forward in the CAD workflow for injection molded parts. The result? The ability for designers to quickly validate changes in real-time when they model.

Throughout this blog, we’ll be looking at a typical workflow when using Molded Part Designer, and how designers can implement these tools to add real value. Let’s take a look!

Setting the scene

Everything throughout the following blog will focus on this coffee machine, using tools in NX to optimize and refine the final design. In the context of Molded Part Designer, we’ll be taking a look at the exterior shell. The shell consists of four different parts that snap together. These parts are all fully featured with standard elements needed for traditional injection molded manufacturing. We’ll take a look at those standard elements later on in the blog.

Accessing Mold Part Designer in NX

Molded Part Design can be accessed in the applications tab. The tab for Molded Part Designer will appear above the Command Ribbon. Designers can work in an assembly context, or use these additional commands on existing unparameterized piece parts. Additionally, there’s a customizable Molded Part Design template available for designing new parts with embedded best practices.

Adding the standard elements to the coffee machine

Rectangular Grooves

Rectangular Grooves are a common feature when separate molded parts need to fit together. Previously, designers may have needed multiple commands like Sketch and Extrude to add this to a design. This command ensures designers can achieve the same outcome with a few clicks.

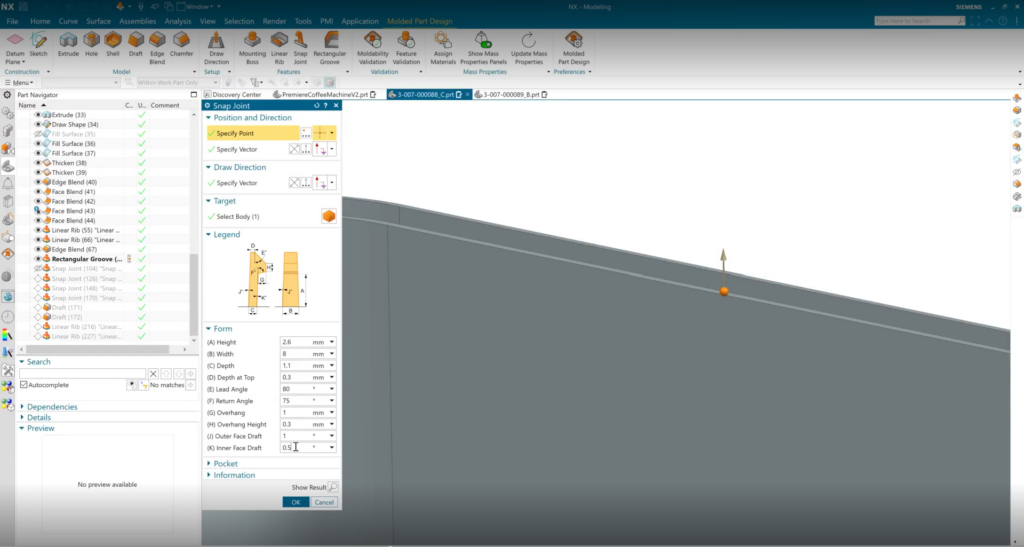

Snap Joints

Snap Joints can be even more time-consuming to model manually. However, they are useful for producing easily manufacturable parts that fit securely together. Molded Part Design’s Snap Joints command provides designers with total control over the geometry for Snap Joints through a quick and easy-to-use interface. All that needs to be done is to specify points that need Snap Joints and adjust the Form values to achieve the correct geometry.

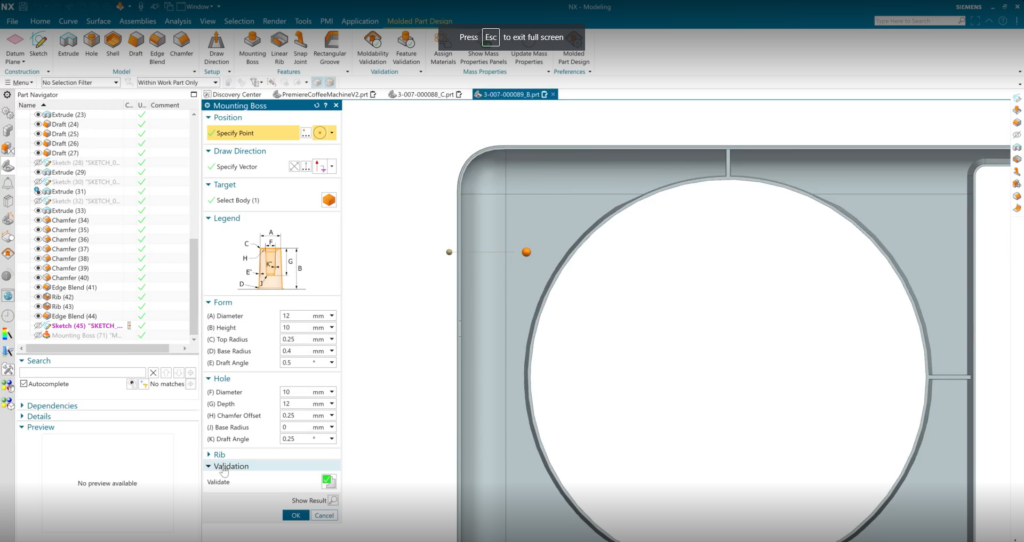

Mounting Bosses

Mounting Bosses are another essential feature when assembling molded parts. Taking the coffee machine shell, it has a complex geometry that would take a while to model from sketches. With Molded Part Design, you can reduce the time taken to create the Mounting Bosses with a single command. similar to Snap Joints, specify a point for the Boss, and you’ll have the option to fully customize the geometry for the Boss’s Form and Hole.

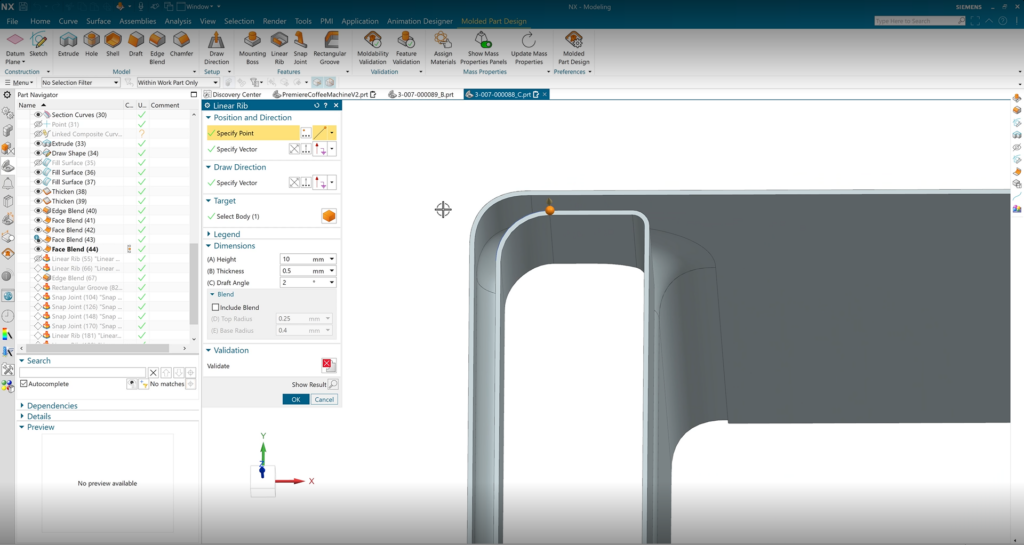

Linear Ribs

Molded Part Design includes an enhanced version of the Rib command to help create these vital features. This new Linear Rib tool has a new workflow, and is fully compatible with Molded Part Designs’ validation tools.

The standard rib Rib command involved sketching a line for the Rib to follow. With Linear Rib, designers specify a point where the Rib will start, and then specify vector. Designers have complete control over height, thickness and draft angle, and also have the ability to add a Blend

Drafting

It’s important to remember that all vertical faces which will be injection molded need to draft applying to reduce the risk of manufacturing faults. All that is needed for this is to select the face or faces you want to apply Draft and enter the required draft angle.

Validation

Molded Part Design empowers designers to validate designs as they work Integrating these validation tools directly into the CAD workspace accelerates design iterations and left-shift risk within the overall product development cycle. All validation parameters can be customized to match specific manufacturing processes, and can be set on a session-by-session basis or across all users in an organization.

Let’s take a look at different levels of validation that can be applied to a model.

Basic validation

This is built directly into the modelling commands previously mentioned. If we focus on the Mounting Boss command, we can instantly validate from the dialog in order to get instant feedback on a wide range of manufacturability criteria. What this does is enable us to tweak the design accordingly.

Feature Validation

Features that are already on the molded can be validated using the Feature Validation report. Running the report shows all validation results in the Molded Part Design Navigator. Relevant parts are also highlighted on the model in the Graphics Window, giving users several options to manage results and focus on specific areas.

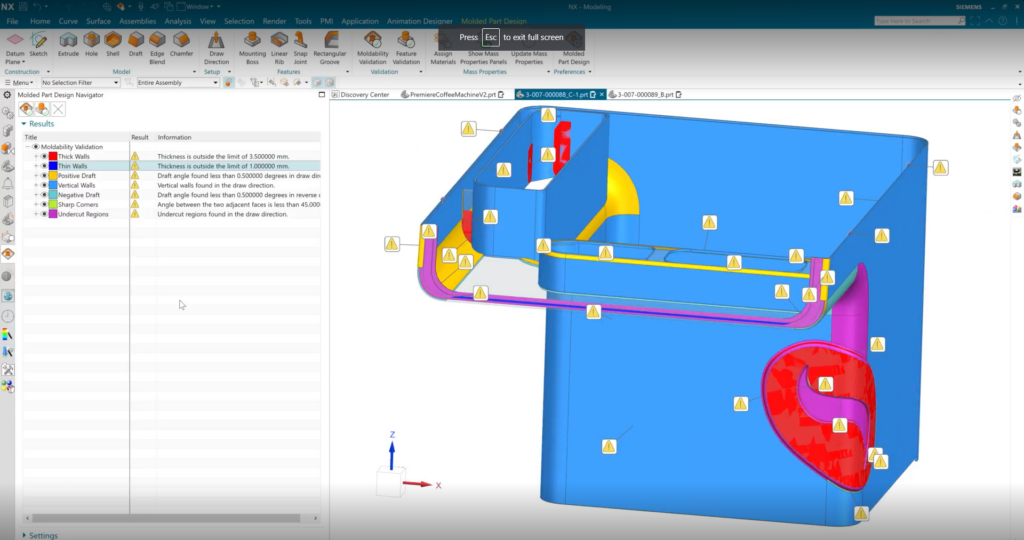

Moldability Validation Report

Finally, designers can also run a Moldability Validation report to check for common manufacturability issues. The report will highlight a variety of potential failure points in any given design. It will identify:

- Walls that are too thick or too thin

- Areas of positive or negative draft

- Vertical walls

- Sharp corners

- And Undercut regions

It’s a powerful tool that makes it quick and easy to identify any potential problems, and whether changes are needed.

Continue your journey with NX

And that wraps up this episode on Molded Plastic Design. These new features will enable designers to ideate higher quality injection molded parts in a fraction of the time previously. Additionally, with the validation tools available, tweaks can be applied to ensure designers truly optimize their parts, ready for manufacturing.

Be sure to continue your journey with NX by following the links below 👇