NX Case Study: SAMS

Four years ago, SAMS decided to change its 3D computer-aided design (CAD) solution to facilitate the work of its designers. “The software we used was purely associative; it didn’t enable using files in the absence of a real structure for assembly and it was difficult to use,” says María Dolores Bautistacerro, a designer at SAMS. “At the time, every designer was working separately with their own tools and parts. It wasn’t really collaborative, with one server shared and a library of parts.”

Challenges:

- Expand business opportunities

- Provide superior service to multinational companies

- Execute projects with significant technical requirements

- Increase productivity

- Provide high-value products

Keys To Success:

- Enable staff to quickly adapt to process changes

- Create a collaborative environment

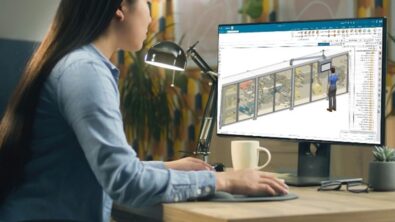

- Integrate NX and Teamcenter

- Utilize synchronous technology

- Leverage power of Siemens PLM Software technology

Results:

- Increased productivity by approximately 20 percent

- Reduced design time

- Improved traceability of information

- Streamlined workflows, significantly reducing paperwork

- Increased product innovation, enhanced competitive advantage

Industry:

Client’s Primary Business:

SAMS specializes in machining. The company produces a comprehensive portfolio of parts and systems for global automotive, agricultural machinery and heavy equipment manufacturers.

Visit the SAMS Website

Learn more about SAMS use of NX

Jerry