Design for Purpose: Micromaterial Modeling using MultiMech

Welcome back! I’m glad to see you have an interest in how additive processes can radically decrease manufacturing’s sustainable footprint in nearly every industry. Before diving into MultiMech, let’s review on what we’ve previously learned: In the first Design for Purpose Article, I introduced NX lattice structure capabilities for enhanced designs. This optional add-on module allows engineers to design for purpose by reducing part weight, cutting material waste, and improving structural and thermal properties. Building on top of lattice structures, this article will detail the second phase in the full lifecycle workflow. This second phase includes being able to predict how, when, and why advanced materials may fail at the microstructural level. This is possible with the use of Simcenter MultiMech. Multimech is a fully integrated Simcenter software that allows for multiscale material modeling and simulation. It extends the flexibility and robustness of finite element analysis down to the microstructural level, strongly coupling the macro and micro mechanical response. Integrating materials engineering into part design supports the acceleration of the product development lifecycle by predicting failure in innovative materials or shapes, such as lattice structures.

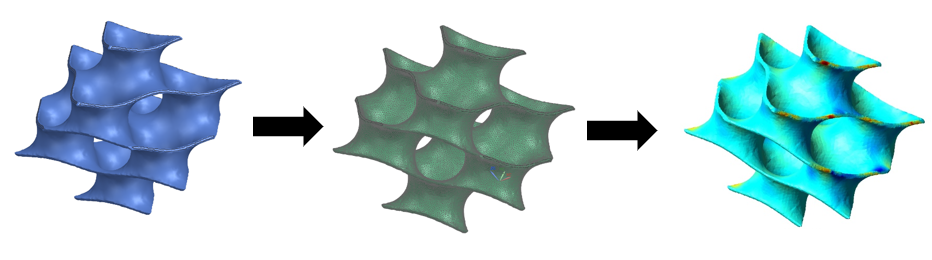

MultiMech aids engineers to simulate and predict advanced material performance by providing three exceptional abilities. The first being the automatic microstructure generation and optimization. You can automatically generate the geometry and meshing of your microstructural models. The only inputs required are basic design variables. You can also quickly and easily apply various loading scenarios to gain insight into how the material will perform in various conditions. The second capability of Multimech is to understand manufacturing variability and imperfections. Simcenter accounts for manufacturing variability and imperfections to maximize product reliability by allowing you to Import process-induced variation data and automatically convert it to microscale, including volume fraction and fiber orientation tensors to simulate injection-molded parts. The third capability of MultiMech is to perform multiscale material modeling. This software enables you to zoom into the material microstructure to identify the root cause of failure and see what damage mechanisms affect structural performance. You’ll be able to optimize your material microstructure for the most cost-efficient performance.

The added value of MultiMech is its ability to replace the vast amount of physical testing needed for certifying and implementing materials for all industry applications. Multimechanics is working to accelerate the product development process by eliminating the need for physical material testing. The need for such physical testing is because new material models require the use of analytical formulations to predict the structural properties and safety qualities. This traditional technique works to some extent. Yet, with the introduction of smart materials and advance engineered structures, like lattice or composite materials, that cannot be changed on a microscale yet in the age of digital technology, this traditional model is becoming obsolete. We start to become less and less predictive through analytical formulations where we observe these materials on how they fail and then fit them to a predefined model. MultiMech does not make predictions based on prior models. Rather, it is reversing that process and building a material from the bottom up. Building it up from the physics of the microstructure allows engineers to be more predicative. You’re directly modelling the physics that occurs on the material level. Doing this advanced material testing is proven to have higher validation than physical observation of materials. There is always some validation on the physical testing and verification, however it does not need to be done for every load case. Simcenter MultiMech gives users the ability to replace physical testing by building ample confidence in your model for some load cases, hence you can then predict it will to work for the other cases instead of having to run more cases and more physical tests.

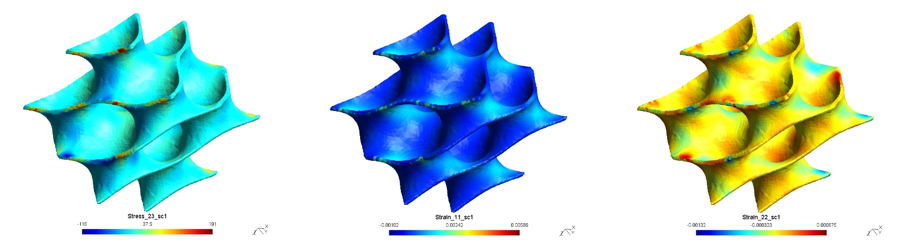

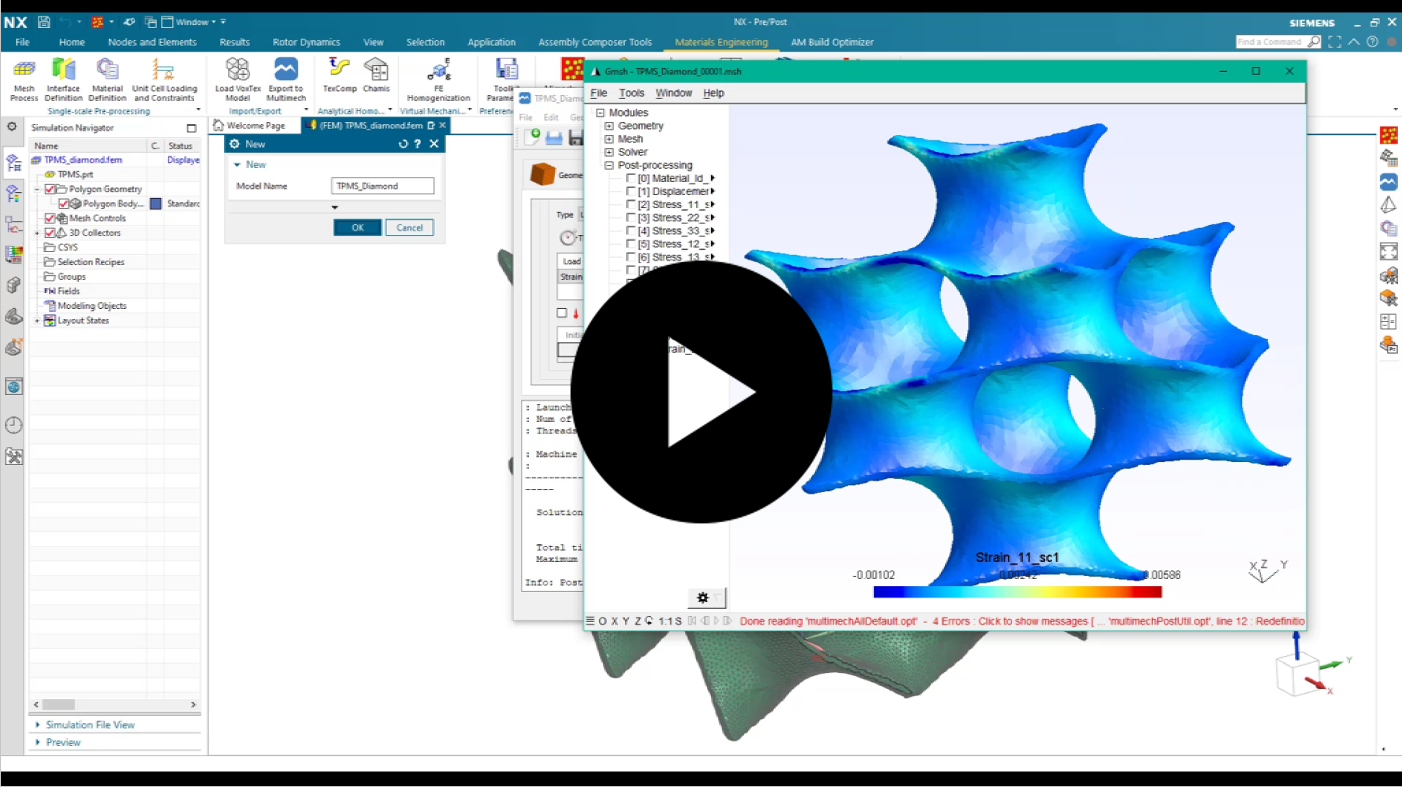

After hearing so much about the awesome capabilities that Multimech possess, I think it’s time we see this process in action! In the following demonstration, I will create a triply periodic minimal surface (TPMS) diamond structure using Implicit Modeling capabilities and import it into a FEM file to mesh the part for use in Multimech. Next, I will use the Materials Engineering tab to export the diamond structure to Multimech to create the needed material file format for analysis. The material of choice is Inconel 625, and it’s known material properties are needed as inputs. Lastly, I will run a simple test by applying a small amount of stress to the structure and analyze the stress and strain results. It’s as easy as 1, 2, 3! After completing the test in Multimech, I save the material file for use in the next step of the lifecycle development workflow.

Now you see how simple it is to conduct detailed material tests with Multimech. You’ll be able to streamline development from months to days and considerably lessen expenses associated with physical testing. At this point, you might be asking yourself “what’s next?”. I would love to answer that question, however just like a good television show, I’ll conclude with a cliffhanger to keep you on the edge of your seats. In the next article I will show how to tie lattice structures and Multimech into virtual simulation to truly confirm that additive manufactured designs perform equal to or even better than traditionally manufactured parts. Is it possible to do this without prototypes and physical structural tests? I guess you’ll have to stay tuned to find out.