Boosting Mechanical Design Team Productivity with CAD Solutions

Executives are focused on boosting the productivity of mechanical design engineers, and rightfully so. Engineers persevere through a challenging workload in the face of shrinking timelines and increasingly complex products. As a result, morale and work quality can suffer.

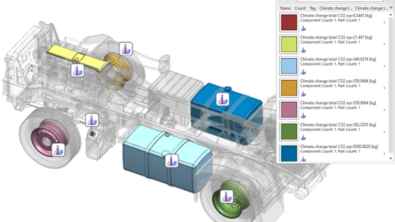

However, organizations that harness new capabilities in CAD solutions can boost mechanical design team productivity.

Seeking Productivity Gains

Increasing productivity is important for manufacturers, especially as they ask their engineers to do more and more. To better understand how new releases of CAD solutions impact engineer productivity, Lifecycle Insights conducted the 2021 CAD Usability study.

In this study, we asked executives about the need to increase the mechanical engineering team’s productivity. Fifty-four percent of study participants cited a need for significant improvement while 40% wanted some productivity improvement. Mechanical engineering teams reported a 6% satisfaction rate from their executives.

Executives can raise employee morale and improve the quality of the finished product by investing in CAD solutions that boost productivity. In this post, we will discuss how new CAD capabilities deliver increased productivity gains to users.

Employee Quality of Work and Morale

There’s an intrinsic link between employee morale and quality of work. When engineers are happy with their jobs, they are more likely to be productive and innovative. Naturally, executives should care—and ideally, care deeply—about these two key performance indicators. And findings from the study showed that. When we asked executives what is motivating them to improve productivity, 36% ranked employee morale and quality of work as one of their top two drivers.

Improving productivity is easier said than done, of course. The design process is filled with mundane tasks like product documentation or checking files in and out of a data management system. Engineers are also expected to help solve product technical issues and manufacturing issues that may arise. These tasks are critical for the company, but they take time away from the design work. As a result, designs take longer to complete.

Engineers’ workloads are getting heavier and more complex, so they often struggle to meet design release deadlines. As they do most of their design and engineering work on CAD solutions, solution providers have an opportunity to implement features that boost productivity.

Automate Interactions with the CAD User Interface

Inefficient processes stifle engineers productivity. Automation is one area with potential for productivity improvements. There are many ways to automate aspects of the CAD user interface, one of which involves macros. Macros are like a tape recorder for your CAD. The tape recorder can be replayed to mimic patterns, such as keystrokes or mouse clicks. Users can automate repetitive tasks in their CAD by deploying macros.

Additionally, engineers can create and use workflow automation scripts without extensive coding. Automation scripts are a way to extend the functionality of a piece of software. These scripts automate time-consuming and error-prone tasks. Once your engineers get the hang of it, they will be able to deploy these scripts without any coding experience.

There are multiple benefits to incorporating automation into CAD solutions. Engineers don’t have to complete repetitive, time-consuming tasks. Instead, they can spend more time tackling challenging problems.

Meanwhile, management can clearly oversee the entire design process and manufacturers can set up the proper workflows. Teams will be able to share CAD automations, and companies can improve efficiency and reduce errors across the board. This further advances the organization’s productivity gains.

Customize the CAD User Interface

Automating interactions with the CAD user interface drives engineer productivity gains, but manufacturers can take their productivity efforts further. Another way to do this is to customize the CAD user interface.

Customization is an effective way to improve productivity. The tricky part, however, is that every mechanical design engineer works differently. So CAD solutions should be slightly different for each engineer. Customization allows users to take charge of the way they interact with their CAD, changing the look and feel as they see fit.

Most CAD solutions allow users to create or modify menu items and toolbars. Users can also create keyboard shortcuts activated by mouse gestures. And customization options don’t end there. Manufacturers can further customize CAD features and tools for the whole organization, while individual users can tweak their individual CAD solutions to best suit their needs.

CAD customization has many benefits. CAD users often collaborate and share their customized CAD user interfaces with each other, for example. This collaboration results in automated workflows and new best practices throughout the organization. Customization also gives engineers more say in their personal design process. That personalization gives engineers a boost in both employee morale and work quality.

Recommendations

Our research indicates executives want productivity improvements from the mechanical engineering team.

One effective way to do this is to reduce the burden of repetitive, mundane tasks through automation features in the CAD solution. Another way lies in CAD customization. Customization can occur on an organizational level, an individual level, or both. The right solution will vary from one organization to the next.

Both options enable engineers to spend more time on high-value problem-solving tasks because they’re not hampered by other responsibilities. Harnessing the full potential of the CAD solution improves employee morale and work quality, which is a win-win across the entire organization.