Introduction to Migration

Introduction to Migration

What is Migration?

Companies have been switching CAD systems for various reasons over the last several decades. The change from one CAD authoring tool to another has many different driving factors, such as better functionality, superior integration to a PLM system, price, willingness of a CAD vendor to work with customers to achieve productivity improvements, or even discontinuation of a legacy system. Regardless of the reasons behind the decision to change CAD tools, though, it’s important that a company still be able to open and modify their existing models and data. This is where a migration tool comes in.

At Siemens PLM Software we call the movement from any SourceCAD system to NX “migration.” Migration also has a second component, the deployment of Teamcenter with NX to create a PLM Environment, which we will discuss in more detail in future posts. Siemens offers a world class solution for executing CAD migrations to NX called Content Migration Manager (CMM.) CMM supports the transition from several SourceCAD systems including I-deas, Catia V4, Catia V5, Pro/Engineer, Creo, and SolidWorks.

Years ago, a CAD “migration” consisted of exporting some type of neutral file format from the legacy system, such as IGES or STEP, and importing that data into the new system. This was problematic due to differing tolerances and the quality of the translator being used. Many CAD changes involved “Remastering,” or recreating the legacy parts, assemblies and drawings in the new system, a very costly and time consuming process. Also, past CAD migrations only focused on parts and not assemblies or drawings due to technical limitations. This meant that all assemblies and drawings would need to be recreated in the new CAD tool.

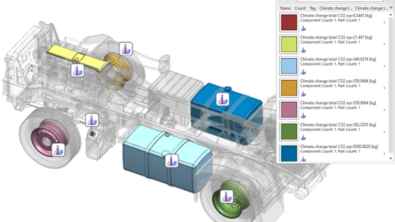

Gone are the days of remastering and file translations when transitioning from one CAD system to another. Content Migration Manager supports both B-Rep and feature migration for parts. Part B-Rep migration consists of migrating the geometry of the part without the feature history. Feature migration involves bringing the features that were used in the SourceCAD system to create the part into NX as modifiable NX features. Assembly relationships are maintained through the migration of the assembly structure, constraints, and assembly level features. Drawings remain associative to the part or assembly from which they were created, which means they are always accurate and up-to-date without requiring a lot of manual work on the end user’s part whenever a change is made. Product Manufacturing Information (PMI) and Sheet Metal are also supported from selected SourceCADs. All of this is accomplished in the managed environment of Teamcenter.

Migrating in a managed environment means that all relationships are tracked and maintained. Also, full reuse capabilities are available, meaning that shared components only need to be migrated once. CMM will find the already migrated part or subassembly and reuse it for occurrences in other assemblies, thus speeding up the transition to NX. For small companies that do not wish to use Teamcenter and want to use NX in a native mode, CMM offers file folder based migration capabilities as well.

Assembly Migrated from Creo to NX with Content Migration Manager

Assembly Migrated from Creo to NX with Content Migration Manager

For inquiries regarding migrating to NX please contact your SPLM representative or GTAC (https://www.plm.automation.siemens.com/en/support/gtac/index.shtml or toll free at 1 (800) 955-0000). Migration activities include performing a sample migration of customer specific data, Initial Audits, Content Migration Manager Training, and development of a Migration Plan.

This article is the first of many that will feature information regarding Siemens PLM Migration tools and strategies. Check back each week on Migration Monday for a new topic.