The future of manufacturing is here: How Siemens and Accenture are bringing the Industrial Metaverse to life

These days, it seems AI is at the center of the conversation in both our professional and private lives.

And while we can discuss the good and the bad, the one area where AI is flourishing is in the realm of manufacturing for large enterprises. This is good news as AI, or more specifically, industrial AI, has proven its value in product development and manufacturing.

In this current era defined by rapid technological evolution, Siemens and Accenture have collaborated with NVIDIA to help bring AI-ready manufacturing into the real world.

Not only do we have the technology and expertise to bring Industrial AI to every machine, device, process or infrastructure, but we also have the capabilities and know-how to bring the Industrial Metaverse to your operation.

Why the Industrial Metaverse?

While the industrial metaverse has yet to be realized, progress is being made every day as there are core technologies already available that provide a path to this future vision. That’s where Siemens, Accenture and NVIDIA come into play. The Industrial Metaverse is a collaborative effort with many contributors.

You can think of Industrial Metaverse as a way to empower your operations to tackle everyday challenges with unprecedented precision and foresight. Teams can simulate and visualize how products will perform under real-world conditions, forecast production outcomes, prevent costly failures and test better solutions in a risk-free digital environment. This experience enables teams to optimize operations from product lines to production flows covering everything from the movement of materials and employees to the latest robotic technology.

The core building blocks behind the Industrial Metaverse

There are a few core building blocks that help advance the Industrial Metaverse, which include the comprehensive Digital Twin, data and AI, and software-defined automation.

By leveraging these core building blocks that help advance the Industrial Metaverse, customers gain a competitive edge, streamline operations and foster stronger collaboration throughout the value chain.

- Comprehensive Digital Twin: A digital representation of a physical asset or process based on powerful, physics-based simulation. This can range from small products to large machines or even entire plants. The comprehensive Digital Twin helps define and optimize products and production systems, significantly reducing the need for physical prototypes before investing in physical assets. Just as critical, the Digital Twin continuously updates to reflect any change to its physical counterpart throughout the product lifecycle, creating a closed loop of feedback in a virtual environment. This enables companies to continuously refine their products, production and supply chain processes at minimal cost.

- Data and AI: The predictive insights gained from AI can lead to optimizations long before human intervention is needed. With AI, teams can converse with the system and identify what caused the issue, pinpointing where to deploy resources to fix the problem. This speeds up the decision and troubleshooting process. If the problem is “deterministic,” a full workflow can be initiated in an Agentic AI approach to resolve the problem.

- Software-defined automation: In the Industrial Metaverse, software-defined elements are ubiquitous, as virtually every product and production environment relies on software to generate data. Further, as digital transformation evolves, automation is moving from hardware-based automation devices to software-defined functionalities. Software-defined automation leverages software mechanisms and applies these benefits to the operational technology (OT) world.

A partnership that offers an Industrial Metaverse blueprint from product development to manufacturing and beyond

Siemens and Accenture share a long record of successfully collaborating to realize large-scale projects for our customers. The partnership has effectively combined complementary strengths including bill of materials (BOM) enterprise management, product lifecycle management (PLM) and manufacturing operations management (MOM). At the core is Siemens Xcelerator, a portfolio of industry-leading software, hardware, and digital services. Siemens Xcelerator offers interoperable industry solutions that span across enterprise systems including PLM, enterprise resource planning (ERP), manufacturing execution systems (MES), SCADA and IIoT – all of which can be seamlessly integrated into both the digital and physical worlds via the Siemens comprehensive Digital Twin.

The key building blocks that contribute to the Industrial Metaverse are also available through the Siemens Xcelerator . Customers can find the latest AI-driven software along with end-to-end manufacturing solutions that can be tailored to their specific needs and challenges.

In the Industrial Metaverse blueprint, the Siemens Xcelerator software portfolio has integrated NVIDIA Omniverse libraries to enable real-time physically accurate and photo-realistic visualization fostering collaboration across engineering and manufacturing domains.

This integration removes the need for users to worry about data formats and allows them to focus on the engineering tasks at hand. NVIDIA AI infrastructure helps to augment the visualization and high-computing capabilities of the Industrial Metaverse experience. The major advantage of leveraging NVIDIA accelerated computing across edge and cloud is that it enables performance and scale which is required to drive the Industrial Metaverse experience.

Siemens has brought a strong partner and leader in digital transformation and services into the fold to accelerate the adoption of technology. Accenture serves as the strategic reinvention partner enabling the global deployment of Siemens’ AI-driven engineering and manufacturing solutions. These offerings integrate NVIDIA AI infrastructure with Accenture’s proprietary accelerators – such as the Physical AI Orchestrator – seamlessly embedded into existing architectures.

Accenture is known for its leadership with strong business planning, strategy consulting, technology innovation and implementation capabilities. Accenture has a successful track record in designing and implementing optimized business operations helping customers transform into a modern digitalized enterprise.

The combined strengths of Siemens, Accenture and NVIDIA create a uniquely integrated software and hardware environment that delivers an intelligent, flexible and scalable Industrial Metaverse blueprint. Further, customers benefit from tailored solutions whether retrofitting existing infrastructure or launching new, purpose-built operations. This collaboration stands out for its ability to deliver scalable transformation, rapid deployment and seamless implementation.

Early signs of the Industrial Metaverse in motion

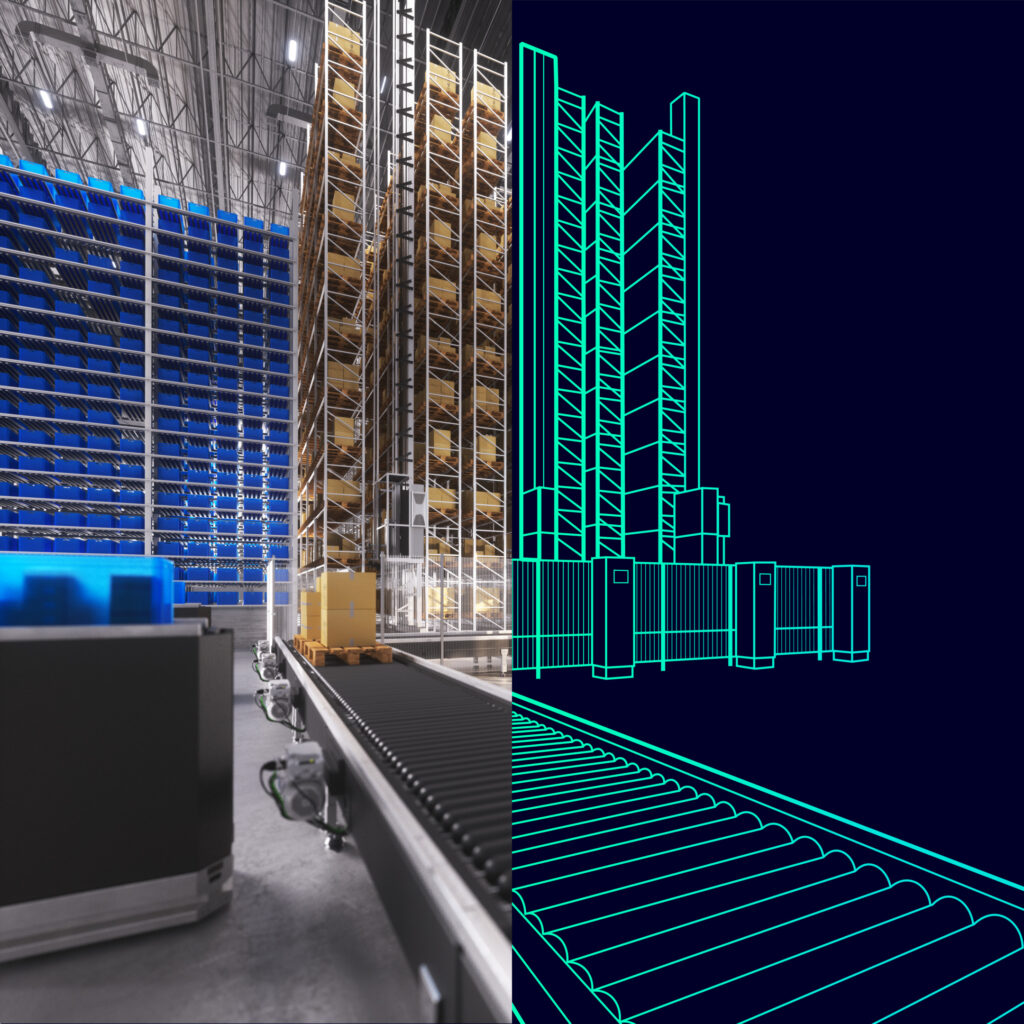

Together, our teams have applied the blueprint to help manufacturers build software-defined facilities. For example, Accenture is using solutions from the Siemens Xcelerator platform together with NVIDIA Omniverse libraries to create a physically accurate and photo-realistic Digital Twin of the plant for a life science company. Once completed, it will enable the manufacturer to gain deep, actionable insights into the layout and operation of the manufacturing site itself, including production lines and other equipment. The digital model can simulate production flows and movement of materials, personnel and robotic vehicles within the facility in real time.

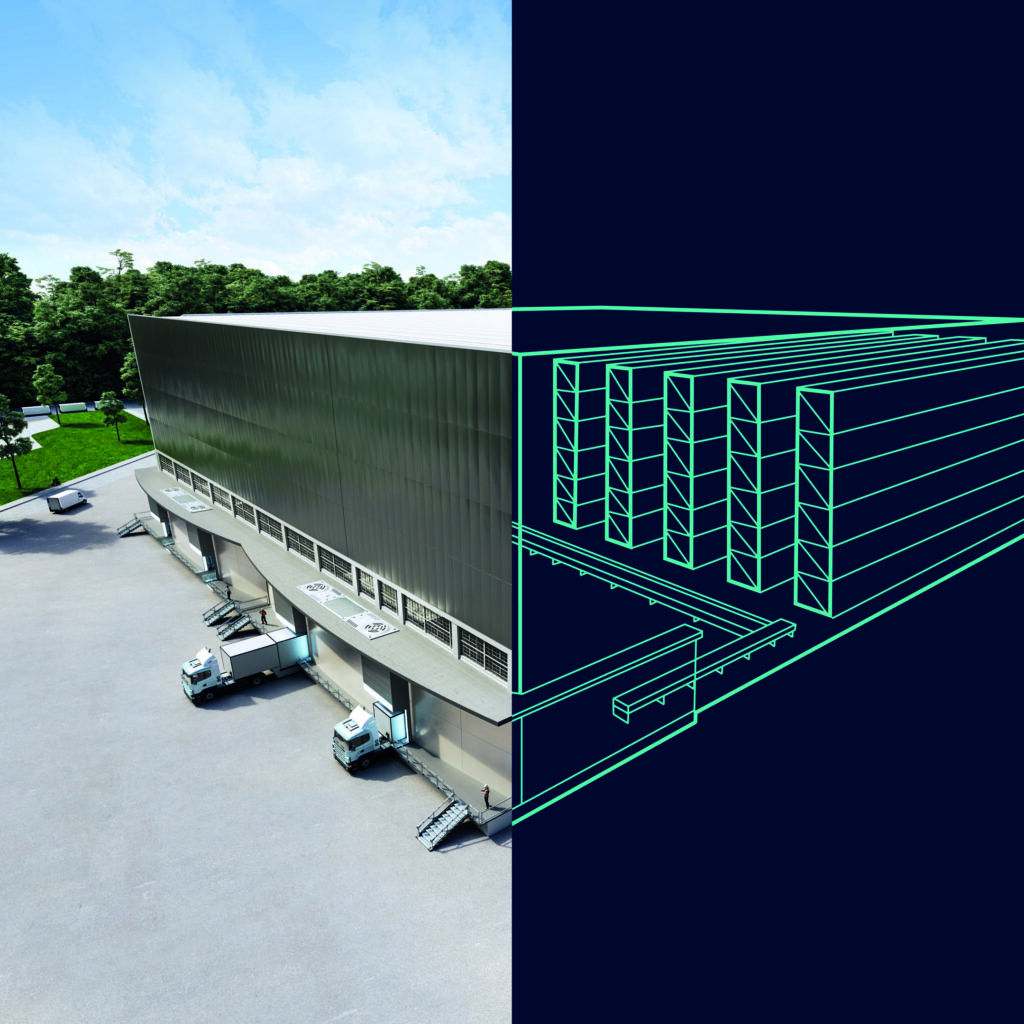

At another manufacturing site, Accenture is using Siemens technology to implement a digital backbone for the company’s product development and engineering processes. This ecosystem with NVIDIA Omniverse libraries – seamlessly integrated – creates a unified environment for designing, simulating and optimizing intelligent warehouse systems. Through the Digital Twin experience, the company can validate warehouse logic in a fully virtual setting accelerating innovation and bridging the gap between digital design and real-world performance.

The Industrial Metaverse can manifest in any number of ways. It isn’t just about advanced technology – it’s about empowering your business to tackle everyday challenges with unprecedented precision and foresight.

One of the industrial Metaverse goals is to enable faster engineering decisions by leveraging precise data from the virtual and physical – interacting with the comprehensive Digital Twin through a single pane of glass.

Let’s start the journey now – together

We are on the brink of a new industrial revolution.

What once took three months to accomplish can now be done in minutes – in real time. The Industrial Metaverse is going to help companies adapt to whatever the future brings.

Together our partnership with Accenture and NVIDIA has developed joint solutions for customers that provide an industry-specific, use-case-driven approach in end-to-end workflows. Whether it’s product, production, operations with comprehensive Digital Twins, simulation, or AI agent-driven automation in manufacturing.

To learn more, visit the Siemens and Accenture and Siemens and NVIDIA partnership webpages. Even better, meet our team at the Siemens booth (North Hall #8725) at this year’s 2026 CES in Las Vegas.

Let’s talk possibilities.