Using co-simulation to improve ship performance

As we’ve discussed previously, there is a push for the marine industry to become more sustainable by reducing emissions and optimizing ships to be more efficient. At the same time, however, ship designers must also adhere to minimum ship power requirements so that a vessel can operate safely in all conditions. Being able to predict the ship/engine interaction is key to meeting these goals.

But how does one go about doing this? The answer is co-simulation enabled by a digital twin.

What is co-simulation?

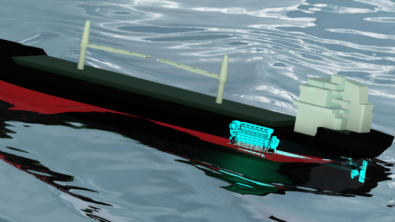

Co-simulation involves coupling 1D system/control software with 3D marine CFD (computational fluid dynamics) software to create a digital twin of the entire ship engine system. While marine CFD simulation is the first step toward a digital twin, combining that with system simulation builds out the digital twin in greater detail. This approach yields more detailed insight into performance.

The benefits of using co-simulation

Using co-simulation to create a complete digital twin of the engine system gives a detailed picture of how the hull and the engine interact. Knowing this makes it possible to predict fuel consumption and emissions in any given sea state.

More broadly, co-simulation allows design teams to avoid problems before they occur and better understand performance before anything is built. Ship designers can be confident about how a ship will perform in various real-world conditions from the outset.

How to learn more about combining hydrodynamics and system simulation

The marine industry must design vessels that meet sustainability goals and regulations while respecting minimum requirements for safe operation. The tools needed to do so are available today; the marine industry simply must adopt them and put them to work.

Watch our on-demand webinar if you’re ready to learn more about co-simulation to predict ship performance. It includes more details on:

- The benefits of coupling 1D and 3D marine CFD simulations

- How and why to use co-simulation, and examples of when to use different approaches

- How to include control systems and rudder coupling in performance prediction

- Prediction of ship fuel consumption and emissions in various sea states

- Examples of minimum power prediction in beam seas