The role of data in manufacturing

“If I only had known that…”

Sound familiar? That phrase resonates deeply across industries, especially in manufacturing, where missed insights can hurt efficiency and lead to significant setbacks. Today, more and more manufacturers are leveraging the potential of one of their most valuable yet underutilized assets: data. When properly leveraged, data in manufacturing can provide the clarity needed to improve productivity, reduce costs, and achieve ambitious sustainability goals.

The challenges in manufacturing are numerous but somehow similar across different manufacturing industries. Disparate companies all face relentless pressure to boost productivity, control costs, manage energy consumption, and contend with a shrinking pool of skilled talent. Yet, data holds the key to overcoming these challenges. By effectively utilizing data, manufacturers can enhance their decision-making processes, leading to more efficient operations, better quality products, and greater flexibility. Moreover, data-driven decision-making plays a critical role in ensuring that businesses can thrive while also meeting environmental responsibilities.

The journey to data-driven manufacturing

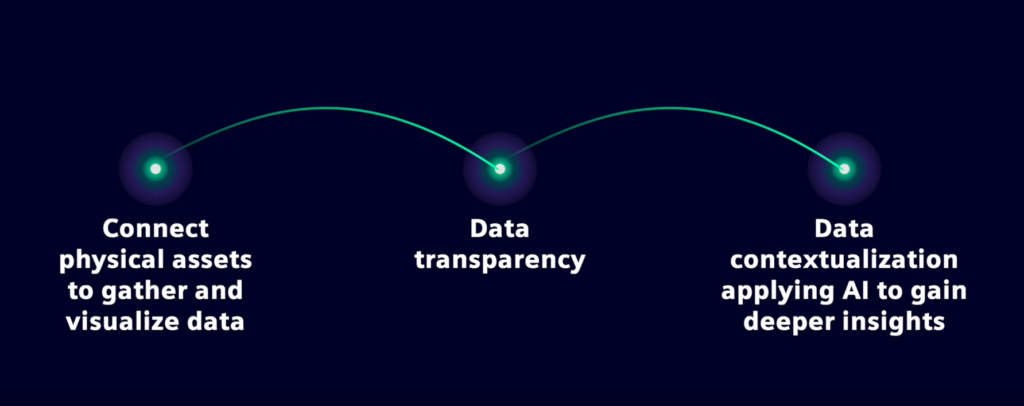

The path to becoming truly data-driven often begins with something simple: harnessing the industrial Internet of Things (IoT) to connect physical assets and collect and visualize data. This step can be transformative, revealing insights that were previously hidden. Imagine flipping on a light switch in a dark room – suddenly, the things you never noticed before become clear. Shining a light on data offers newfound transparency and allows manufacturers to see where improvements can be made, often uncovering opportunities for efficiency that were previously overlooked.

Collecting data is just the start. The real value comes when manufacturers begin to contextualize that data and apply AI to uncover deeper insights. Moving beyond mere data collection, AI-powered tools enable predictive analytics and advanced decision-making, turning raw data into actionable intelligence that can drive real-world improvements.

Real-world success stories and technology trends

Real-world examples show the tangible benefits of a data-driven approach. Consider a scenario where a critical machine vibration anomaly was initially considered a mechanical issue. By analyzing IoT data alongside additional manufacturing execution system (MES) data, the true cause – a problem originating with a material supplier – was identified. This level of insight transforms how manufacturers approach problem-solving, enabling a shift from reactive to proactive strategies.

It’s not just about identifying problems. Data-driven manufacturing also allows for rapid solutions scaling. Some companies have successfully implemented data-driven systems across dozens of plants in just a few months, underscoring the efficiency and scalability of these approaches.

Companies who actually take advantage of data in their operations will have a big impact on their decision-making capabilities, which will improve productivity, lower costs, increase quality and flexibility, and also help them achieve their sustainability goals.”

Dr. Ralf M. Wagner, senior vice president, Insights Hub

Industrial IoT and AI will partner for an exciting future

The future of manufacturing is exciting, with continuous advancements in industrial IoT solutions and generative AI technologies. Imagine AI tools seamlessly integrated into manufacturing operations, providing real-time quality predictions, and guiding operators through complex processes. The concept of a “production copilot” – an AI-driven assistant that helps operators respond to machine alerts and optimize performance – is already on the horizon. This innovation promises to significantly enhance operational efficiency and decision-making, paving the way for a new manufacturing era.

As the industry evolves, those who embrace data-driven manufacturing will be well-positioned to advance and respond to challenges. By leveraging the power of data and AI, manufacturers can unlock unprecedented levels of productivity, efficiency, and sustainability, ensuring they remain competitive in an increasingly complex world.

Learn more about empowering decisions with data insights

So, the next time you hear someone say, “If I only had known…,” remember that you can know with the right data strategies in place – just in time.

Want to dive a little deeper into this topic? Click here to learn more about data-driven manufacturing insights and examples of solutions in action from Dr. Ralf Wagner, senior vice president, Insights Hub.

Or, experience the power of data insights yourself – Start for Free with Insights Hub.