The power of additive manufacturing technology for parts manufacturers

Parts and component manufacturers must constantly evolve to stay ahead of the competition, improve operational efficiency and deliver high-quality products to their customers. Additive manufacturing technology, also known as 3D printing, has the potential to do all those things and revolutionize how parts are manufactured.

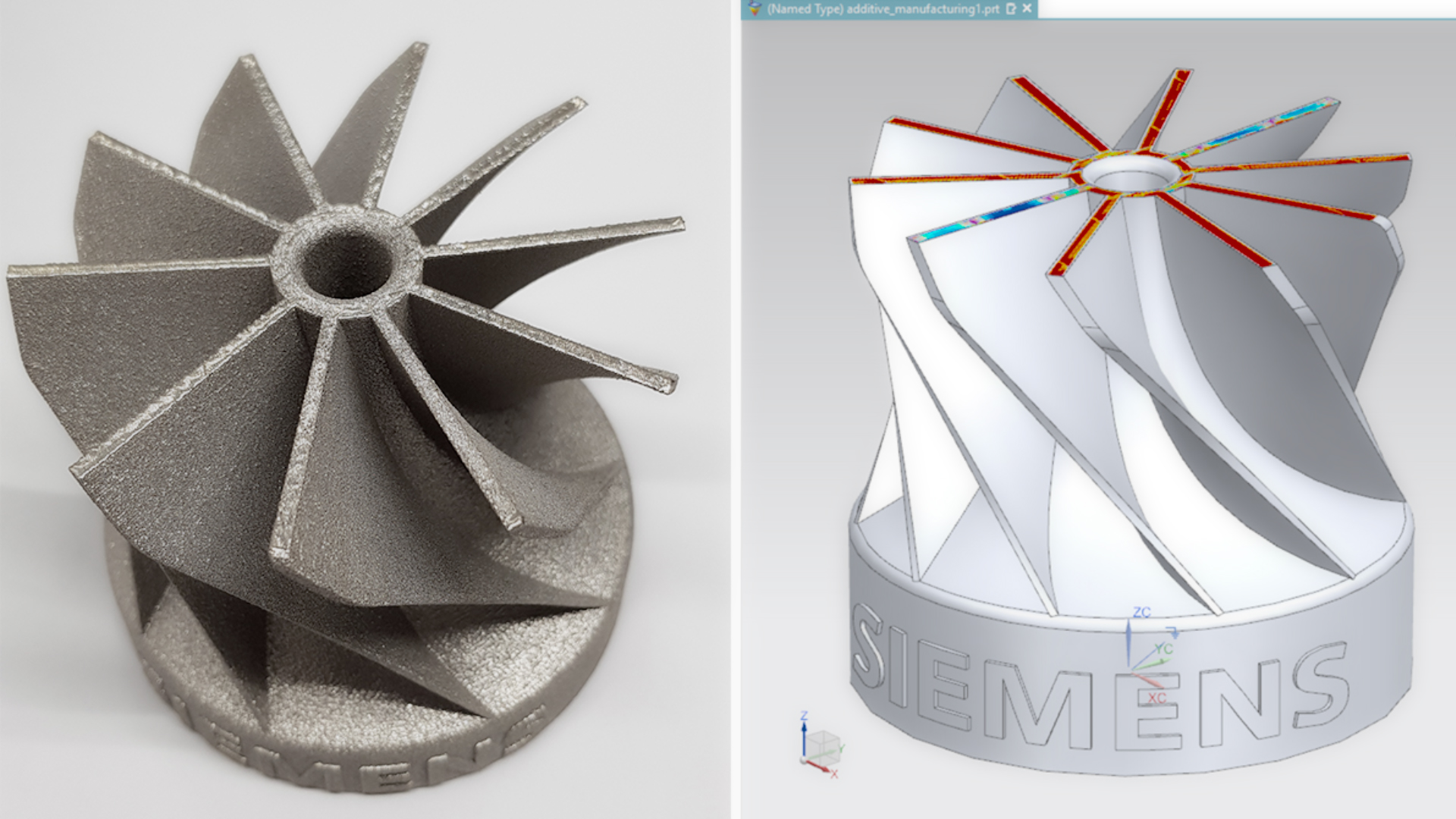

Traditional parts manufacturing methods involve removing material to create a part, but additive manufacturing builds parts layer by layer, unlocking a world of new possibilities. With additive manufacturing technology, parts manufacturers can create complex geometries that were previously impossible, reduce material waste and accelerate lead times.

Additive manufacturing capabilities give machine shops new ways to increase market share with a broader product portfolio. To unlock additive manufacturing’s full potential, machine shops need the right digital tools.

Siemens NX is a comprehensive CAD/CAM/CAE solution that includes robust additive manufacturing capabilities. With NX, machine shops can seamlessly integrate additive manufacturing capabilities into existing workflows, from design and simulation to production and post-processing.

Watch the video for a brief introduction to NX additive manufacturing:

The benefits of additive manufacturing technology for parts manufacturers

Additive manufacturing technology gives parts manufacturers and machine shops three big advantages:

Increased design flexibility: Eliminate design constraints imposed by traditional manufacturing methods. Additively manufactured parts can have complex, organic shapes, internal features and customized geometries that optimize performance, reduce weight and improve sustainability.

Reduced material waste: Additive manufacturing only uses the material necessary to create a part, resulting in significantly less waste, and translates to cost-savings and improved sustainability.

Faster lead times and on-demand production capabilities: Produce parts on an as-needed basis, and eliminate the need for large inventories and associated storage costs. A just-in-time production model can help you better manage your supply chain and respond more quickly to customer demands.

Unlock these benefits to stay ahead of the curve and begin designing and building the sustainable and reliable parts your customers need.

With NX, you can streamline your entire additive manufacturing workflow, from design and simulation to production and post-processing.

Learn more about additive manufacturing with Siemens NX AM.