Boost heavy equipment simulation capacity with CAE software

With a rise in software-driven functionalities, digital capabilities and electrification, unmanaged or manual processes used in heavy equipment design can drag down efficiencies and even compromise product development cycles. To explore all options for innovations through continuous verification and validation, to train algorithms for smart machine capabilities or for certification of autonomous functions, design teams will need to do thousands, if not millions of simulation runs. This will require powerful computer-aided engineering (CAE) automation capabilities available through CAE software. Heavy equipment manufacturers who are able to combine CAE automation with performance engineering by predicting real product performance will gain a competitive edge as the industry continues to innovate and adapt.

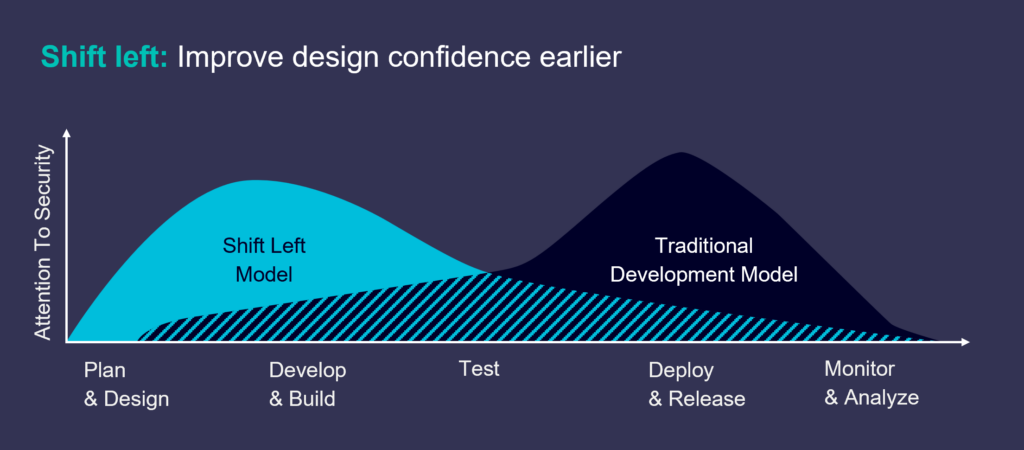

By automating engineering simulation processes and workflows, heavy equipment manufacturers can achieve a massive shift left to resolve issues early in a product’s lifecycle. Discover how seamless CAE automation can help you make critical decisions earlier to drive more efficient product development in today’s complex heavy equipment industry.

A new level of simulation efficiency with CAE software

Innovative technologies within the heavy equipment industry will require CAE automation to explore thousands of options and decide which one works better for your application. Millions of simulation runs will be necessary to validate and certify autonomous and connected equipment. Smart machines need automated simulation scenarios to optimize performance after delivery.

CAE software allows manufacturers to deliver results in real time, during development for controls verification and validation or for machine learning, for certification purposes, or as part of the operation.

So how exactly can a heavy equipment manufacturer use CAE automation to attain new levels of simulation efficiency? One Siemens heavy equipment customer adopted a modeling and simulation solution capable of analyzing and predicting system performance on the mechanical, hydraulic, thermal and electrical levels.

This video highlights a few key results French construction equipment manufacturer Mecalac achieved using CAE software automation:

Read the Mecalac case study to learn more details about how their modeling and analysis phase was completed in just three months for the world’s first fully electric wheeled excavator.

Another Siemens heavy equipment customer used advanced simulation and CAE automation to transition to an electric motor. Read the Haulotte case study to see more about how they reduced the number of prototypes and the time spent on testing campaigns.

Interested in how other heavy equipment OEMs used advanced simulation software to reduce costs? Read the ebook to see more results here:

Heavy equipment design exploration

By adding CAE automation, you can unlock numerous opportunities to frontload design decisions and ultimately achieve massive efficiency gains. This is particularly the case if you use automation to engage your simulation models in large-scale design exploration. These technologies allow you to discover totally new designs, fully tuned to the requirements with unprecedented performance.

Most analysis setups recur to some extent, so putting those parts in templates can save a significant amount of time. The larger their scope, the better. Comprehensive templates that integrate the work of various departments help to standardize processes and are a good basis for large-scale workflow automation.

Mature your CAE data and process management

Does your product lifecycle process suffer from any of these obstacles?

- Manual imports and exports of CAD and CAE data

- Unmanaged simulation data and processes

- Models come too late to truly drive the design

Successfully running simulation scenarios requires accuracy and immediate results and allows engineers to reduce the manual work involved in analysis to accelerate product development cycles. Performing CAE analysis in the same environment as CAD design allows you to develop automated workflows that span both disciplines, speeding up the development process.

Siemens CAE software includes advanced technologies that boost efficiency for all steps of the simulation process including:

- Fast data processing

- Meshing

- Solving

- Reduced-order modeling

- High-performance computing

Siemens software solutions provide heavy equipment manufacturers with all the necessary tools for CAE automation in any context. Explore all the resources Siemens has to offer and how you can start applying Predictive Performance Engineering here:

Ready to dive into more detail about CAE software solutions? Below are resources developed exclusively for heavy equipment manufacturers:

Ebook: CAE software for heavy equipment manufacturing

Resource Library: Predictive performance engineering for heavy equipment

Resource library: High-end simulation and testing technologies

Blog: How CAE automation enables agriculture innovation

Free trial: Seamlessly integrate all performance engineering aspects