Article Roundup: Hydrogen Powered Cars, On-Demand DRC with P&R, AV SoC Functional Safety, Automating CDC Verification & Advanced Packaging LVS and LVL issues

- Betting on Hydrogen-Powered Cars

- On-demand DRC within P&R cuts closure time in half for MaxLinear

- Functional Safety Verification For AV SoC Designs Accelerated With Advanced Tools

- Automating the pain out of clock domain crossing verification

- Mentor unpacks LVS and LVL issues around advanced packaging

Betting on Hydrogen-Powered Cars

SemiEngineering

Hydrogen fuel cell vehicles are a compelling alternative to internal combustion vehicles and battery electric vehicles. Hydrogen provides an environmentally friendly fuel source without the long recharging times and range anxiety that have hampered electric vehicles thus far. However, fuel cell vehicles are still costly to purchase and maintain, and are lacking in fueling infrastructure. Despite these challenges, the automotive industry is continuing to develop these vehicles as part of the future of mobility.

Hydrogen fuel cell vehicles are a compelling alternative to internal combustion vehicles and battery electric vehicles. Hydrogen provides an environmentally friendly fuel source without the long recharging times and range anxiety that have hampered electric vehicles thus far. However, fuel cell vehicles are still costly to purchase and maintain, and are lacking in fueling infrastructure. Despite these challenges, the automotive industry is continuing to develop these vehicles as part of the future of mobility.

On-demand DRC within P&R cuts closure time in half for MaxLinear

Tech Design Forum

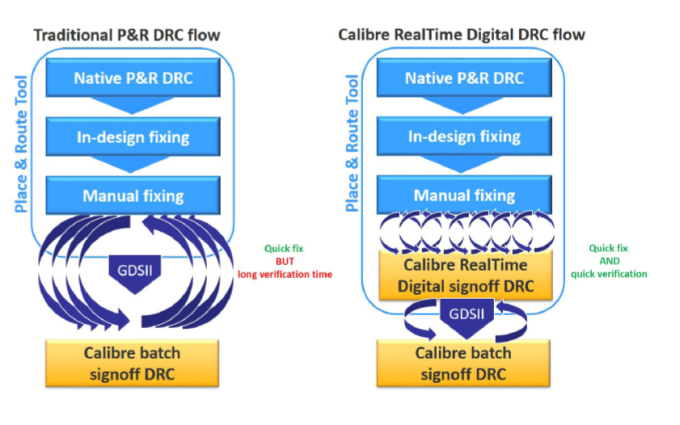

A newly published case study describes how MaxLinear’s digital design team was able to use Calibre RealTime Digital to perform on-demand design rule checks (DRC) during place and route. MaxLinear, a specialist in RF and AMS CMOS systems, used the RealTime Digital suite to generate dynamic feedback for engineers as they worked, without leaving the place and route environment. According to MaxLinear, the process allowed it to meet its constraints and cut physical verification closure time in half for each design iteration at both established and advanced process nodes.

A newly published case study describes how MaxLinear’s digital design team was able to use Calibre RealTime Digital to perform on-demand design rule checks (DRC) during place and route. MaxLinear, a specialist in RF and AMS CMOS systems, used the RealTime Digital suite to generate dynamic feedback for engineers as they worked, without leaving the place and route environment. According to MaxLinear, the process allowed it to meet its constraints and cut physical verification closure time in half for each design iteration at both established and advanced process nodes.

Functional Safety Verification For AV SoC Designs Accelerated With Advanced Tools

SemiEngineering

AV manufacturers will need to demonstrate the safety and reliability of all aspects of their self-driving systems to earn the trust of a wary public. This article examines how an advanced suite of verification tools can help these companies meet rigorous functional safety standards and demonstrate the safety of their AV SoCs.

Automating the pain out of clock domain crossing verification

Tech Design Forum

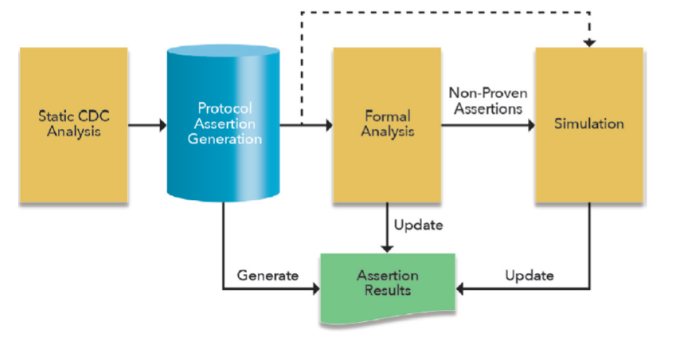

Clock-domain crossing is the second most frequent cause of respins on IC designs. Avoiding these issues requires complex and time-consuming verification, simulation, and debug processes. This article describes a new methodology that automates manual processes related to setup and debug, and a strategy to improve the results gained from the process.

Clock-domain crossing is the second most frequent cause of respins on IC designs. Avoiding these issues requires complex and time-consuming verification, simulation, and debug processes. This article describes a new methodology that automates manual processes related to setup and debug, and a strategy to improve the results gained from the process.

Mentor unpacks LVS and LVL issues around advanced packaging

SemiWiki

Advanced packaging has played an important role in improving system performance and reducing area. Advanced packaging also introduces new challenges in packaging verification for which mature PCB and IC LVS and LVL strategies cannot be easily applied. Read more to learn how advanced software solutions can help resolve these challenges.