Article Roundup: 5G, Deep Learning, Embedded Interrupts, Hardware-Centric HLS Code Checking & Faster Post-Silicon Debug & Test

- Gearing Up For 5G

- Delving into Deep Learning

- Interrupts in the Nucleus SE RTOS

- A hardware-centric approach to checking HLS code before synthesis

- Accelerating Post-Silicon Debug and Test

Gearing Up For 5G

SemiEngineering

5G is expected to jumpstart exciting new capabilities in several markets including automotive, mobile, and the IoT. The new wireless standard will provide orders of magnitude improvements in communication speed and latency, leaving systems companies to decide whether to process their data locally or in the cloud. The choice these companies make will, to a certain degree, determine semiconductor architecture decisions going forward, from processor and memory to power budgets and more.

5G is expected to jumpstart exciting new capabilities in several markets including automotive, mobile, and the IoT. The new wireless standard will provide orders of magnitude improvements in communication speed and latency, leaving systems companies to decide whether to process their data locally or in the cloud. The choice these companies make will, to a certain degree, determine semiconductor architecture decisions going forward, from processor and memory to power budgets and more.

Delving into Deep Learning

Electronic Design

What is deep learning? According to Chris Rowen, CEO of BabbleLabs, it is “the construction of a complex numerical model that mimics the behavior of an even more complex but hidden system. The hidden system in question is often the brain.” But, Rowen contends that an understanding of how deep learning differs from AI and machine learning is important to fully understand deep learning and its implications at the application level. Rowen spoke on this topic at a recent summit hosted by Mentor’s Emulation Division.

What is deep learning? According to Chris Rowen, CEO of BabbleLabs, it is “the construction of a complex numerical model that mimics the behavior of an even more complex but hidden system. The hidden system in question is often the brain.” But, Rowen contends that an understanding of how deep learning differs from AI and machine learning is important to fully understand deep learning and its implications at the application level. Rowen spoke on this topic at a recent summit hosted by Mentor’s Emulation Division.

Interrupts in the Nucleus SE RTOS

Embedded.com

Interrupts in microprocessors and microcontrollers provide the responsiveness necessary for many applications. However, this can conflict with the functioning of a real-time operating system that also aims to be responsive and predictable. Colin Walls explains how Nucleus SE handles interrupts to address this conflict.

Interrupts in microprocessors and microcontrollers provide the responsiveness necessary for many applications. However, this can conflict with the functioning of a real-time operating system that also aims to be responsive and predictable. Colin Walls explains how Nucleus SE handles interrupts to address this conflict.

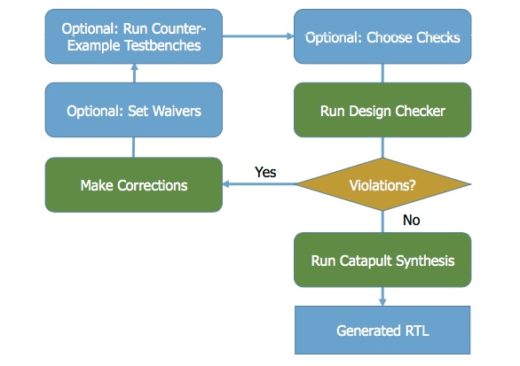

A hardware-centric approach to checking HLS code before synthesis

Tech Design Forum

Traditionally, finding issues in C++ or SystemC code before passing it to high level synthesis (HLS) was tricky, potentially slowing the adoption of HLS. The crux of the problem is that static software analysis tools were not designed to understand hardware intent. Now, a new hardware-centric combination of static and formal verification techniques resolves the main limitations of previous approaches.

Traditionally, finding issues in C++ or SystemC code before passing it to high level synthesis (HLS) was tricky, potentially slowing the adoption of HLS. The crux of the problem is that static software analysis tools were not designed to understand hardware intent. Now, a new hardware-centric combination of static and formal verification techniques resolves the main limitations of previous approaches.

Accelerating Post-Silicon Debug and Test

SemiWiki

SoC designers are using more embedded IP, creating a challenge for post-silicon bring up and slowing time-to-market. This is partially due to the inherent inefficiencies of current silicon bring-up and debug flows that involve multiple transitions of test collateral. This article examines a new flow that enables DFT engineers to observe IP directly in the SoC under test.

SoC designers are using more embedded IP, creating a challenge for post-silicon bring up and slowing time-to-market. This is partially due to the inherent inefficiencies of current silicon bring-up and debug flows that involve multiple transitions of test collateral. This article examines a new flow that enables DFT engineers to observe IP directly in the SoC under test.

Comments

Leave a Reply

You must be logged in to post a comment.

PCB is almost ubiquitous in automotive electronic systems

The popularity of automotive electronics will push up the price and quantity of PCB (printed circuit board) in automobiles. In recent years, the trend of automobile electrification and electronization is obvious, and PCB is almost ubiquitous in automobile electronic system.

The PCB consumption of new energy vehicles is nearly four times that of traditional fuel vehicles, and the price of bicycle PCB is more than 1,200 yuan. Nowadays, a lot of PCBs are needed in the vehicle chargers, DC-DC converters, inverters and battery management system for new energy vehicles. The penetration and total volume of domestic new energy vehicles are in the forefront of the world, and the high growth rate will be maintained in the next few years. Relevant PCB suppliers will benefit significantly.

Intelligent driving components such as millimeter wave radar will increase the demand for end PCB. Because the circuit frequency of millimeter wave radar is as high as 24_ GHz, the material, dielectric properties and precision requirements of PCB and upstream copper clad board are much higher than those of ordinary PCB, which makes the unit price of PCB 3-10 times higher than that of ordinary PCB. With the continuous penetration of intelligent driving equipment, the market of high-end PCB will erupt.

Conservatively, it is estimated that the domestic PCB market will reach 24.1 billion yuan in 2025, the global market will reach 58.3 billion yuan, and the CAGR will be about 12% in 2018-2025. China’s leading PCB manufacturers’revenue will grow faster than the market.

Automobile business has become the main business of many A-share listed PCB manufacturers, and contributed to the main part of revenue growth in recent years. In 2018, the PCB share of the top six automotive companies in A-share listed companies is about 12%, which is significantly higher than the 10% in 2017. Since the new century, PCB industry has gradually moved eastward, and the share of domestic production in the world has increased from 17% to more than 50%. As an important downstream producer of PCB, China’s global share of automotive business of PCB manufacturers is expected to continue to increase.

The technology of domestic PCB manufacturers has improved significantly in recent years. Shanghai Electric Power Co., Ltd. (002463.SZ) is the leading domestic automotive panel company actively participating in international cooperation, introducing advanced technology. High-frequency PCB used in millimeter wave radar has achieved mass production. At the same time, many PCB manufacturers have realized the coverage of new energy automotive electronic systems such as downstream power batteries and charging.

Domestic automotive PCB business will play an increasingly important role in PCB manufacturers’revenue growth. At the same time, with the rapid development of domestic downstream, domestic PCB enterprises will be able to obtain a certain share from multinational enterprises. http://www.pcbindex.com/

The value of intelligent manufacturing

Be it industrial 4.0 in Germany, industrial internet in the USA, or China intelligent manufacturing 2025 in China, the core lies in intelligent manufacturing. Why nations around the globe are all racing to upgrade the traditional manufacturing to intelligent manufacturing? There is no doubt that intelligent manufacturing can really bring value to manufacturers, thus increasing a nation’s comprehensive national strength. Which nation is faster in this aspect means which country is developing fast in terms of economic growth.

What kind of value will intelligent manufacturing bring to the PCB enterprises? According to Li Zhongjie, manager of the Marketing Department from Rockwell Automation Co., Ltd., Internet of Things plays a crucial role in the intelligent manufacturing value chain as adopting the technology of Internet of Things can help to collect the latest data from the relevant manufacturing enterprises, such as control components, production parts and automatic production line, which enable the administrator of the factories to make more intelligent decisions based on these data, thus generating such concepts such as intelligent factory, intelligent manufacturing.

There is no denying that industrial machine technology and the upper stream industrial software technology also play an important role in this process. Furthermore, combined with the Internet, Internet of Things can be connected to the supply chain and demand chain of the manufacturing enterprises as well. Administrators and operators can adjust the production plan of the factories in time in responsive to the demands of changing market from the external environment and achieve flexible production in order to improve the responsiveness ability and production efficiency, shorten the full life cycle of the products, increase the asset use ratio and reduce the risk of resource waste as well, which are all values brought by intelligent manufacturing. http://www.pcbindex.com/

Flexible manufacturing can not only help to switch the production of different products in different models in the workshop at any time but also to arrange the production schedule based on orders from the clients. At present, this kind of flexible production has been already introduced to the factories of some manufacturing enterprises, such as, car manufacturing, electronics production line.