Article Roundup: Digitalisation, IoT Energy Harvesting, Hybrid Emulation, Improved PCB DFM & Low-power CPU Design

- Digitalisation is not about taking away jobs: Siemens’s Roland Busch

- Where Is Energy Harvesting?

- Prime Time for Hybrid Emulation and the Shift Left Methodology

- How to Make Design for Manufacturing (DFM) Smarter, Faster, and Leaner

- Designing a low power CPU

Digitalisation is not about taking away jobs: Siemens’s Roland Busch

Forbes India

Digitalization is at the core of Siemens AG’s strategy and investments, according to the CTO Roland Busch. The German conglomerate aims to help companies increase their productivity and enhance the use of their assets by providing software and digital services, which hit 5.2 billion euros in revenue last year. This article provides a recap of an interview conducted with Mr. Busch on Siemens’ digital strategy and the effects of digitalization.

Digitalization is at the core of Siemens AG’s strategy and investments, according to the CTO Roland Busch. The German conglomerate aims to help companies increase their productivity and enhance the use of their assets by providing software and digital services, which hit 5.2 billion euros in revenue last year. This article provides a recap of an interview conducted with Mr. Busch on Siemens’ digital strategy and the effects of digitalization.

Where Is Energy Harvesting?

SemiEngineering

The ability to extract energy from environmental conditions, such as heat or vibration, could be the key to addressing power needs for IoT applications. However, most contemporary development is focused on energy management and increasing the efficiency of chip designs to meet the power needs of IoT devices. Yet, as demands for IoT device functionality and processing power increase, even very efficient designs will eventually need to supplement battery-stored power. Energy harvesting is an attractive option when that time comes.

Prime Time for Hybrid Emulation and the Shift Left Methodology

EE Web

Hybrid hardware-software emulation enables design teams to adopt a “shift-left” testing methodology, thus accelerating embedded software development. Hybrid emulation is more agile than traditional emulation and facilitates software debug much earlier in the design process while freeing up space on the emulators. However, challenges to adopting this shift-left methodology include integrating hardware and software design, and encouraging the engineering teams to accept such a change.

How to Make Design for Manufacturing (DFM) Smarter, Faster, and Leaner

EMS Now

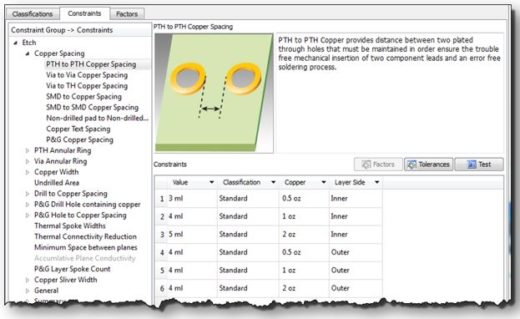

PCB complexity is steadily increasing as the market demands electronic products that pack more functionality into smaller packages at lower cost. Design for manufacturing (DFM) solutions should efficiently handle this increased complexity to create products that meet market demands. This article examines two steps to improving DFM for PCBs, and the benefits this has for advanced PCB designs.

PCB complexity is steadily increasing as the market demands electronic products that pack more functionality into smaller packages at lower cost. Design for manufacturing (DFM) solutions should efficiently handle this increased complexity to create products that meet market demands. This article examines two steps to improving DFM for PCBs, and the benefits this has for advanced PCB designs.

Designing a low power CPU

EDA Café

Low-power chip design traditionally has been viewed as a hardware problem in which the solution was addressed solely in the electronic design. Now, however, managing the power consumption of a design is firmly within the software domain. Here, Colin Walls explains a novel trick to limiting power consumption by minimizing the number of logic transitions.