Embedded systems in cars – challenges and solutions

Complexity never, in itself, impresses me. I am impressed people’s ability to understand complex ideas and create complex machines, but a truly elegant and simple solution is always what gives me most pleasure. This might beg the question as to why I work in software – a business well known for creating incredibly complex things. I often ask myself the same question.

Systems where there are safety issues are a particular concern and a context, which is of interest to us all, is automotive systems …

When I first got a car [in 1975] there were really no electronic systems in vehicles at all. A few high end models had “electronic ignition”, but that was very primitive analog electronics that barely counts. That has all changed. Modern cars – even basic models – have dozens of microprocessors and microcontrollers, which span the complete spectrum of power/complexity from tiny 4-bit controllers to monster 32-bit [maybe 64-bit] supercomputers on a chip. Every system is electronic and a variety of design approaches are applicable. As I discussed in a previous post the degree of safety criticality in automotive systems varies and this has a significant effect on how they are implemented.

I am not a specialist in the automotive business, but I observe a particular characteristic which seems specific to car makers: they are very keen on standards. I believe that this comes about because, apart from being good business practice to take standards-based approaches to design when possible, the auto industry has a complex supply chain, so compliance with standards is easier to manage than individual, very detailed specifications. Some of the standards that apply to electronic systems in cars [not an exhaustive list]:

- CAN Bus – a means to reliably connect numerous systems together whilst minimizing the amount of wiring.

- MISRA C [and C++] – a detailed set of guidelines in the use of this language in a safety critical system, like a car.

- OSEK/VDX – a standard for real time operating systems used in such systems in cars.

- Genivi – a standard for Linux based systems used for in-car infotainment systems.

Although MISRA C has always interested me, I am particularly focused on the two operating system standards.

OSEK/VDX is a standard for RTOSes destined for use in automotive control systems. It was designed from the ground up for this purpose and incorporates the key characteristics needed for a safety critical system. The key feature is a lack of dynamic objects; everything is created statically at build time. The intrinsic simplicity of this implementation makes total sense to me, as it does not constrain the software designer significantly and eliminates a significant potential source of system failure. It is unsurprising that other industries are taking an interest in the standard. OSEK/VDX RTOSes are available from a number of vendors; it is also encompassed by AUTOSAR, which is a broader standard.

Most of the driver-facing systems in a car are not hard real time and do not have harsh safety requirements. So Linux is a good choice, as it opens up the availability of a wide range of off-the-shelf software components. Genivi is a standard for the implementation of Linux in this context. Mentor Embedded not only provides the Automotive Technology Platform, but is very active in maintaining and advancing this important standard. A recent announcement details support for Genivi 5.0. This on-demand Web seminar is a useful introduction to Genivi deployment.

Most of the driver-facing systems in a car are not hard real time and do not have harsh safety requirements. So Linux is a good choice, as it opens up the availability of a wide range of off-the-shelf software components. Genivi is a standard for the implementation of Linux in this context. Mentor Embedded not only provides the Automotive Technology Platform, but is very active in maintaining and advancing this important standard. A recent announcement details support for Genivi 5.0. This on-demand Web seminar is a useful introduction to Genivi deployment.

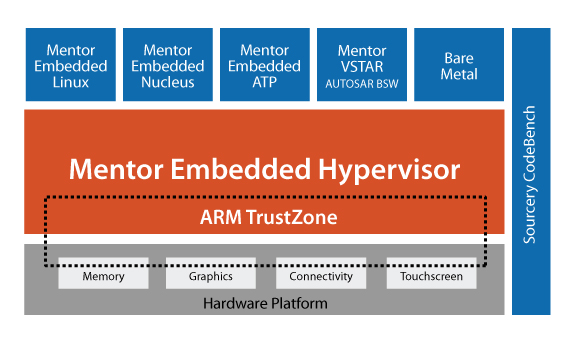

The complexity of automotive systems means that deployment of a hypervisor, such as Mentor Embedded Hypervisor, becomes very attractive. This ensure isolation between sub-systems, thus increasing security and reliability.

The complexity of automotive systems means that deployment of a hypervisor, such as Mentor Embedded Hypervisor, becomes very attractive. This ensure isolation between sub-systems, thus increasing security and reliability.