3D Printers for Printed Circuit Boards!

Technology companies have been using 3D printers for years now for everything from rapid prototypes, product development and data visualization. Models for everything from industrial electronics, to fashion jewelry to teeth have been 3D printed. Since 2005, versions of 3D printers have even become available and affordable for the serious hobbyist. Imagine, instead of having to run to the store to buy a holiday cookie cutter, simply downloading the desired 3D model and print it out at home. All of the sudden that magical “replicator” that I thought was so cool as a kid watching the Star Trek TV series doesn’t seem so far-fetched.

“Yep! Just finished the PCB design, its printing now!”

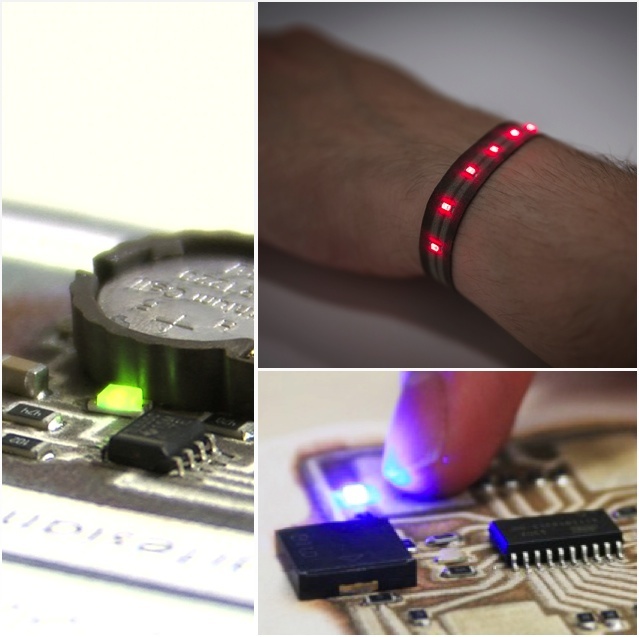

Utilizing 3D printing for circuit boards is no longer in its infancy with significant progress made with printing designs on different materials including plastic, glass, ceramics and paper. Items like wearable electronics, paper circuits and even printed computers have been successful. We can expect to see support for even more substrate materials as these 3D PCB printing companies continue to advance the technology.

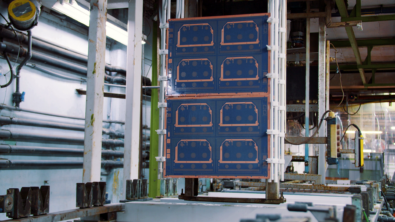

Photo courtesy of Cartesian Co.

Photo courtesy of Cartesian Co.

If you are interested in learning more about 3D circuit card printing check out the now fully funded EX1 project here on Kickstarter by Cartesian Co. They have some really neat examples of fully functional PCB assemblies printed on fabric along with the more familiar substrate materials mentioned earlier. if you’d like to see some fun paper circuit board assemblies in action, check out Printoo, an Arduino-based platform of paper-thin, low-power boards and modules that enable you to bring power, even solar, to 3D products using internet and Bluetooth connectivity, including modules for motorization, light and motion sensing.

Thanks for reading!

John

Comments

Leave a Reply

You must be logged in to post a comment.

I am seasoned PCB designer of 25+ years and a HUGE fan of rapid prototyping in the form of 3D printing. Since getting involved with 3D printing, I’ve often thought it would be fantastic to have the ability to print a circuit at your desktop for prototyping purposes. Unlike the LPKF machines that score a copper sheet from a sub-straight, the additive process is much cleaner. With the LPKF option, you are limited to available sub-straights with no method of multi-layer construction. In theory , a 3D print of a board – you can lay the sub-straight in one pass and lay the copper etch on a second pass. Like the mechanical 3D print, you could layer up the board creating metalized feed-through’s (vias) essentially creating a multi-layer construction. Esentially LDI Meets FDM or SLA ! I have now doubt OEM’s and Electronic Manufacturing Companies as well as existing PCB fabricators will embrace such a tool.

Mike Brown – Pesident of Interconnect Design Solutions