What is the Model Based Enterprise? And how does it impact the aerospace value chain?

Digital technology has seeped into all facets of our lives.

It’s everywhere.

It’s affected the way we stay informed… The way we interact with friends and family… The way we travel… How we purchase items.

Now it’s changing the way we design, manufacture, and maintain things in the industrial world.

Already digitalization has impacted our industrial and manufacturing models in a profound way. The pace of innovation and the ability to disrupt traditional approaches are key differentiators among those who will succeed in this new world and those who will be left behind. The pace of innovation also increases the pressure on partners, suppliers, and key players up and down the supply chain – the aerospace and defense industry is no exception.

Indeed digitalization is changing every A&D subsegment, disrupting leaders, and creating new business opportunities for the swift and innovative. To survive manufacturers and their supply chain must rethink every aspect of their business, transition to a digital enterprise, and take advantage of the new and disruptive technology drivers across each phase of operation. The top aerospace and defense manufacturers, as well as agencies of the US Department of Defense, leverage and trust Siemens Digital Industries Software, to drive digital transformation across all phases of their operations to execute programs more effectively, securely and profitably.

The Model Based Enterprise approach

Members of the aerospace and defense industry face ever-increasing risks and opportunities as the world around them transitions to a digital ecosystem.

Implementing the Model Based Enterprise (MBE) is an essential aspect of gaining digital competency, allowing organizations to transform their business processes through digitalization. Rather than simply replacing paper-based documents with digital versions MBE employs digital models of a product’s design, manufacturability, and sustainment to automate and better manage the overall product lifecycle.

Think of it this way. A full MBE means there are no drawings or paper documents. There’s less paperwork. And those clumsy hand-offs between teams and independent data systems are significantly reduced. MBE represents an evolutionary shift from a paper-based to a connected digital work environment. It brings together multiple engineering disciplines to electronically collaborate and share up and down the value chain.

Already, industry leaders are affirming the need for the MBE. Kristen Baldwin, U.S. Acting Deputy Assistant Secretary of Defense for Systems Engineering, recently stated…

“We are shifting toward a dynamic digital engineering ecosystem. This digital engineering transformation is necessary to meet new threats, maintain overmatch, and leverage technology advancements.”

Kristen Baldwin

U.S. Acting Deputy Assistant Secretary of Defense for Systems Engineering

U.S. Department of Defense

Realizing the electrical MBE

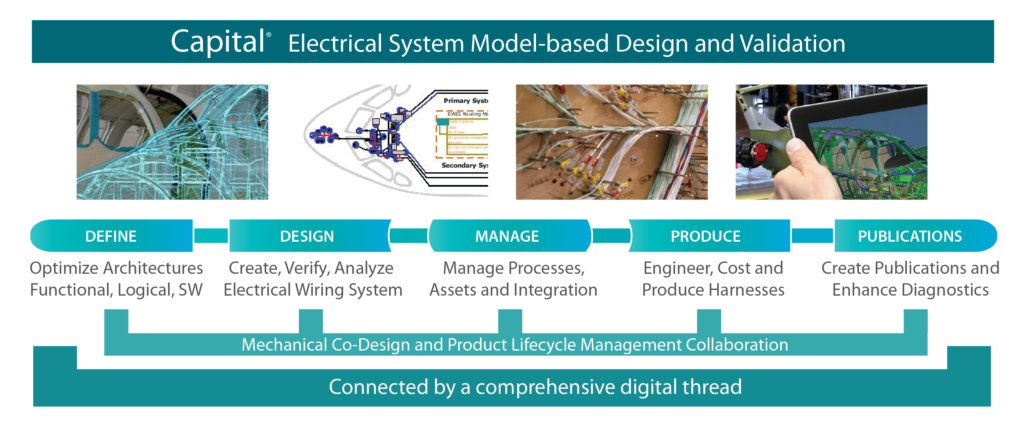

An aerospace or defense platform consists of multi-domain systems that are carefully integrated to perform its intended design functions. Tools with the capability to deliver advanced automation across a flow extending from electrical/electronic architecture definition, through detailed electrical design and wire harness manufacturing, to documentation and diagnostics are essential. These tools need to smoothly integrate with other design disciplines, such as mechanical computer-aided design tools, systems engineering tools, and manufacturing/shop floor systems.

Capital software leading the way

Siemens has been working diligently for nearly two decades to enable a complete MBE flow for the electrical aerospace discipline. The result is Capital, a software environment architected upon the principle of digital data continuity, built to capture and enrich the electrical digital twin from define and design to publications of an electrical aircraft platform.

The Siemens Capital tool suite helps organizations reduce risk and improve productivity. While there are many advantages to using Capital, the three that jump to mind include:

- Capital communicates changes back and forth across the value chain so that systems engineers, design engineers, and manufacturing teams aren’t blind-sided by improvements proposed by one of the other teams.

- Capital interrogates the electrical system digital twin to report violations to critical compliance rules, such as signal separation and electrical load analysis, as they occur. For more details, check out the Siemens Capital Load Analyzer tool.

- Capital controls access to critical intellectual property to protect program teams from unauthorized disclosure of information.

Step into the future

It’s an exciting time to serve the aerospace and defense communities and Siemens is leading the digital transformation with proven and comprehensive digital technologies. This digital transformation promises to move forward at an even faster pace given the many challenges the industry faces today. An interesting study by the Organization for Economic Cooperation and Development (OECD) found that organizations that build digital competency into their organization not only gain up to 25 percent in overall productivity, they also become part of the top five percent of performers in their respective industry.

Siemens provides the A&D industry with a flexible ecosystem that combines both an open software platform and rapid application development to easily build, integrate and extend data and existing systems. Leveraging the breadth of the Xcelerator portfolio combined with access to technology and solutions partners across the globe, Siemens has created a series of adaptable digital threads that enable aerospace and defense companies and governments to optimize their operations, to successfully, safely and securely execute the most challenging programs that are transforming air travel, space exploration and defense.

For more information on how you can start transitioning to the electrical MBE, visit Capital’s electrical system design for Aerospace and Defense website.

To see the complete offering of Siemens A&D digital solutions, please visit the Siemens Aerospace and Defense website.