Why manufacturing’s $100 Billion blind spot is costing you more than you think

A shocking reality: While supply chain disruptions cost global businesses $184 billion annually, most manufacturing companies remain blind to their biggest optimization opportunity—the factory floor itself.

The numbers don’t lie. Recent industry data reveals that 76% of companies experienced supply chain disruptions in the past year, with costs averaging 6-10% of annual revenues. Yet here’s what most executives miss: the solution isn’t just about managing external suppliers or optimizing transportation routes. It’s about the invisible 30-40% of your supply chain that operates behind your factory walls.

The intralogistics market is exploding toward $112.17 billion by 2030, driven by manufacturers who’ve discovered that internal material flow optimization can deliver 15-20% operational efficiency improvements and reduce downtime by up to 35%. But here’s the disconnect—most facilities still treat their internal logistics as a separate operational concern, missing critical opportunities that forward-thinking competitors are capturing.

Download “Beyond Warehouse Management” now and join the manufacturers who are moving beyond traditional logistics to orchestrate end-to-end supply chain excellence.

The cost of the internal blind spot

Picture this: You’ve invested millions optimizing your external supply chain, tracking every shipment from suppliers to your dock. But once materials cross your facility threshold, they disappear into a black box until they emerge as finished goods. This artificial boundary is where billions in efficiency gains are lost.

Traditional logistics management has created a dangerous gap. While sophisticated systems track goods between facilities, the critical internal movements within factories operate through disconnected, manual processes. The result? Production delays, excess inventory, increased operational costs, and diminished customer satisfaction—all stemming from what should be the most controllable part of your supply chain.

Consider the real impact:

- Manufacturing productivity increased 4.5% in Q1 2025, yet most of these gains came from companies who integrated their internal logistics with broader supply chain strategies

- Supply chain optimization can reduce costs by up to 25%, but only when internal operations are included in the equation

- Warehouse management systems deliver measurable ROI through increased productivity, reduced errors, and improved customer satisfaction, yet many manufacturers haven’t extended these benefits to their production floors

Beyond the warehouse: The Opcenter IPL advantage

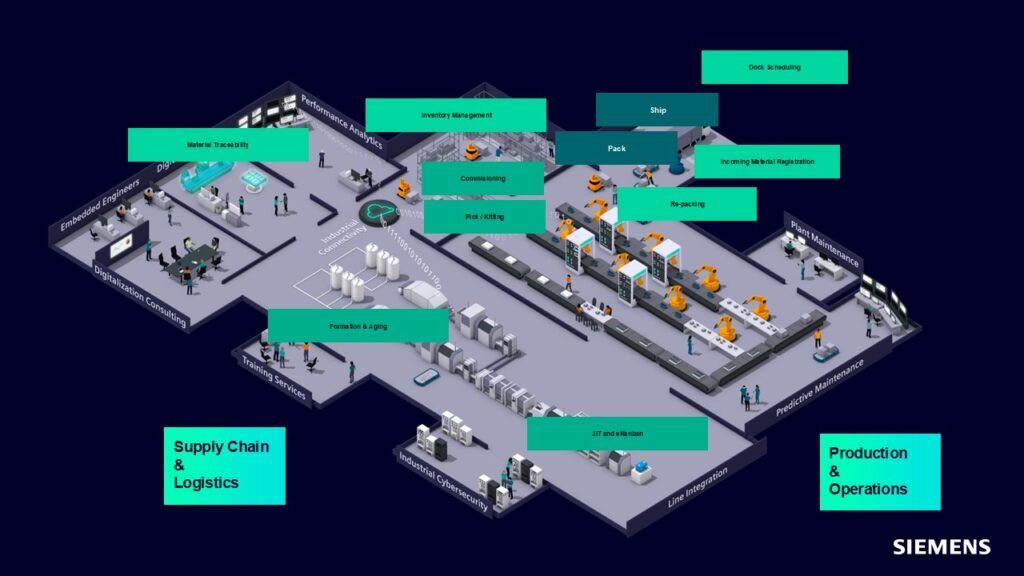

This is precisely why Siemens developed Opcenter™ Intra Plant Logistics (IPL)—to eliminate the artificial boundary between external logistics and internal operations. Our latest e-book, “Beyond Warehouse Management,” reveals how leading manufacturers are transforming their facilities into intelligent, responsive hubs within their broader supply chain networks.

Opcenter IPL addresses the core challenge: connecting internal chain operations. By providing real-time data integration, the solution captures detailed information on material consumption and movement through sensors, scanners, and connected equipment. This granular operational data creates unprecedented visibility into material flow patterns, usage rates, and potential bottlenecks.

But here’s where it gets powerful—when integrated with the broader Siemens Digital Logistics ecosystem, including AX4™ and Supply Chain Suite (SCS), Opcenter IPL enables manufacturers to orchestrate end-to-end supply chain excellence:

- Opcenter IPL provides the foundation for accurate, real-time tracking within the plant

- AX4 acts as a logistics execution platform, connecting with partners and enabling dynamic production schedule adjustments

- SCS provides comprehensive supply chain visibility for predictive analytics and risk management

Real-World impact: From cost center to strategic advantage

The transformation delivers measurable benefits across multiple performance dimensions:

Reduced Lead Times: Streamlined internal material flow eliminates bottlenecks that previously extended production cycles. Components become readily available when needed, enabling faster production cycles and shorter overall lead times.

Enhanced Responsiveness: Real-time data allows organizations to quickly detect changes in demand or supplier performance and adapt accordingly. Production schedules adjust based on material availability while resource allocation optimizes to address emerging priorities.

Minimized Disruptions: Proactive risk management capabilities identify potential issues within the internal chain before they impact production. Combined with external supply chain visibility, this enables comprehensive risk management that prevents cascading failures.

Cost Optimization: Streamlined material handling reduces labor costs and equipment requirements. Optimized inventory levels minimize both carrying costs and stockout risks, while efficient space utilization improves facility ROI.

The integration imperative

The intralogistics landscape is evolving rapidly, with AI integration, warehouse automation, and robotics driving 9.4% CAGR growth through 2030. Organizations that treat internal logistics as isolated systems miss the strategic value realized through broader integration.

This isn’t just about efficiency—it’s about proactive risk management and continuous supply chain optimization. The integration between Opcenter IPL and broader supply chain systems creates a virtuous cycle where internal operations become more visible and controllable, making external planning more accurate and effective.

Consider the competitive advantage: While your competitors struggle with disconnected systems leading to inefficiencies and missed opportunities, integrated solutions like Opcenter IPL transform internal logistics from operational necessity into strategic capability.

The path forward: Transform your manufacturing ecosystem

The future belongs to manufacturers who embrace integrated intralogistics solutions. The question isn’t whether to optimize your internal material flow—it’s whether you’ll lead the transformation or watch competitors capture the advantage.

Download our comprehensive e-book “Beyond Warehouse Management” to discover how Opcenter IPL integrates with broader supply chain solutions, addresses specific manufacturing challenges, and delivers concrete benefits across multiple operational scenarios. Learn from detailed use cases covering logistics planning, manufacturing replenishment, transport management, and pick-pack-ship operations.

The digital supply chain revolution is reshaping manufacturing. With supply chain disruptions intensifying and the intralogistics market expanding toward $100+ billion, the time for integrated solutions is now.

Ready to transform your manufacturing facility into an intelligent supply chain hub? Discover how Opcenter IPL, as part of the Siemens Digital Logistics ecosystem, can eliminate your operational blind spots and deliver sustainable competitive advantage.

Download “Beyond Warehouse Management” now and join the manufacturers who are moving beyond traditional logistics to orchestrate end-to-end supply chain excellence.

Don’t let supply chain complexity limit your growth. The integrated approach to intralogistics isn’t just the future—it’s the competitive advantage your organization needs today.