Closing the loop: How logistics enables the circular economy

The transition toward a circular economy is no longer an abstract ambition – it’s becoming a business imperative. Yet, while diagrams of circularity often show the flow of resources from raw materials to recycling, they rarely explain how products and materials actually make their way through this cycle. The missing link is logistics and supply chain management.

At every stage of a product’s lifecycle, logistics and supply chain management form the backbone of circularity. They connect the players, enable transparency, and create the efficiency needed to keep resources in motion rather than letting them become waste.

Logistics as an enabler – and a responsibility

The role of logistics in supporting circularity is twofold. On the one hand, supply chains make circular models possible by ensuring products, components, and materials move where they need to be – whether for manufacturing, reuse or recycling. On the other, the sector itself has a significant footprint: emissions in the supply chain can be 26 times higher than a company’s own operational emissions.

Addressing this imbalance is crucial, especially in the face of material shortages, ESG regulations and the increasing complexity of global networks. Forward-looking companies are rethinking their strategies to promote long-term sustainability and resilience.

In a recent presentation we explored how supply chains can help organizations “close the loop” and unlock new opportunities for efficiency, innovation and sustainability. Yu can watch the full recording here. If you would like to learn more about this topic, download the white paper about how to make logistics the center of the circular economy.

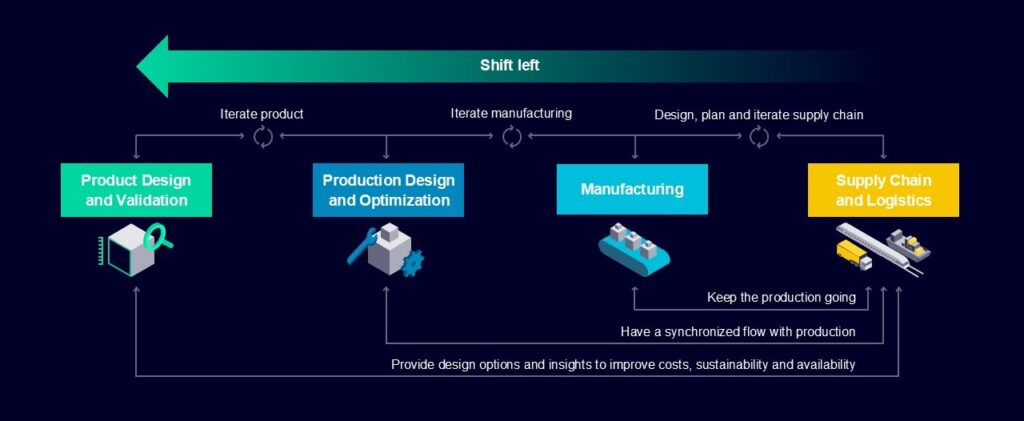

Shifting left – and right

A key insight is that 80% of a product’s environmental impact is determined during the design phase. That’s why Siemens advocates a “shift-left” approach in logistics: embedding sustainability considerations as early as possible in the product lifecycle.

But designing for circularity is only part of the story. To truly close the loop, organizations also need to “shift right” – optimizing logistics processes throughout production, distribution and end-of-life recovery. From product design and sourcing to recycling, each step offers opportunities to reduce emissions, increase efficiency and reclaim valuable resources:

- Product Design & Sourcing: Evaluate recycled materials and balance cost, risk and environmental impact at the earliest stage.

- Supply Chain Network Design: Optimize routes, capacity utilization and transport modes to lower emissions and cost.

- Inbound Logistics: Use end-to-end digitalization to consolidate shipments and optimize resources.

- Intralogistics & Warehousing: Streamline material flows and reduce energy consumption in facilities.

- Production Scheduling: Leverage real-time visibility to adapt plans and avoid energy-intensive ramp-ups.

- Outbound Logistics & After-Sales: Apply simulation-based planning and packaging optimization for smarter transport and spare-parts delivery.

- Collection & Recycling: Track and trace recyclable materials and plan return flows for reintegration into production.

Real-world examples

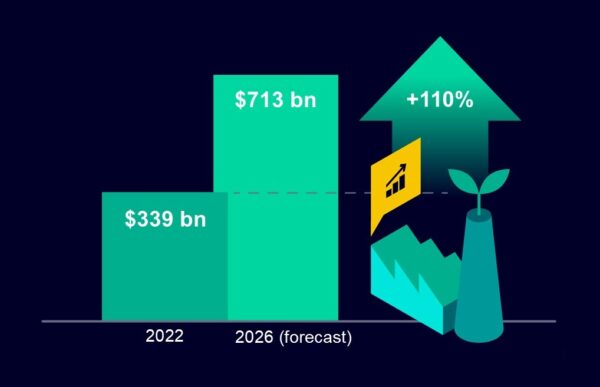

Circularity is not just good for the planet; it makes clear economic sense. In 2022, circular economy transactions generated $339 billion in revenue, with forecasts suggesting a rise to $713 billion by 2026 – a 110% increase.

While few companies are truly circular end-to-end, many are adopting elements that support sustainable supply chains. A few examples that illustrate how logistics innovation drives both environmental and business value:

- Molex, a manufacturer of electronic, electrical and fiber optic connectivity systems, reduced bill-of-materials analysis by 70% using Supplyframe’s Design-to-Source Intelligence platform.

- The logistics service provider REICHHART Logistik uses Supply Chain Suite to optimize truck deployments by consolidating partial loads into efficient round trips. One specific customer project illustrates impressive results such as a reduction in emissions by 22%.

- Already since ages, LEDER und SCHUH, one of the largest shoe companies in Europe, relies on AX4’s tracking and supply chain event management features. As a result in terms of efficiency, the container utilization improved by over 15%.

- The South Americanwhite appliance manufacturer Embraco improved machine utilization and cut buffers by 9% using Opcenter Intra Plant Logistics as material management and replenishment solution.

- Trek Bicycle Corporation doubled production planning capacity and avoided shutdowns using Opcenter Advanced Planning and Scheduling.

- Ford Europe enhanced efficiency and communication in spare-parts logistics with a supply chain control tower based on AX4.

- Although it is not a recycling use case, BASF is a perfect example for tracking and tracing which is a major requirement when talking about “collecting and recycling”. Using AX4 The chemical company reduced paper-based transport documents by 86% while improving global sample management.

Key takeaways

- Logistics and supply chain management are essential enablers of the circular economy.

- Sustainability begins early – design and sourcing decisions set the tone for a product’s entire footprint.

- To succeed, organizations must break down silos and integrate data, processes and partners across the lifecycle.

By embedding sustainability into design, execution and recovery, and by leveraging digital tools to gain visibility and optimize flows, logistics can help businesses close the loop – and build a more resilient, regenerative future.