The power of insight: Rethinking supply chain decision making – part 2

Supply chain management is at a crossroads. Traditional, reactive approaches are no longer sufficient to navigate the complexities of today’s global marketplace. To thrive, organizations must embrace a proactive, data-driven strategy.

This is part two of a two-part series (see Part 1). We delve into the challenges hindering effective supply chain management and explore how a culture of data-driven Supply chain decision making can unlock new opportunities. We will examine real-world case studies to illustrate the transformative power of advanced analytics and strategic planning.

Join us as we embark on a journey to rethink supply chain decision-making and discover how to harness the power of insight to drive business success.

Short recap

In part 1 of our exploration into optimizing supply chain management, we addressed predominant challenges faced by many organizations. These include a reactive approach that increases operational costs and stifles innovation, a lack of transparency in key metrics that impedes informed decision-making, and a prevailing status quo bias that prevents dynamic responses to changing market conditions.

To combat these issues, we discussed the importance of fostering a data-driven culture within supply chain networks. This involves empowering teams to engage in “what if?” scenarios with the support of transparent, real-time data. We illustrated how transforming decision-making processes can reduce the marginal costs of strategic and tactical inquiries and enhance the efficiency of operations. A detailed case study of a leading international mechanical manufacturer highlighted these principles in action. By integrating disparate data sources into a unified planning database and employing advanced analytics, the team was able to restructure their supply chain network effectively, leading to improved global service levels and cost efficiencies. (See The power of insight: Rethinking supply chain decision making – part 1)

As we proceed to the second part of our discussion, we will delve deeper into another case study focused on intralogistics challenges and see the same principles in action again. Additionally, we will introduce a self-assessment approach that can help organizations gauge their supply chain transparency and readiness to adapt to dynamic market demands. We will conclude with the strategic insights gained and outline actionable next steps for organizations aiming to implement the discussed principles.

Case study 2: Enhancing warehouse efficiency and service level

Context: The spare parts division of an agricultural machinery manufacturer faced significant challenges with its central warehouse operations. Operating out of multiple facilities with a sum of >100,000 sqm warehouse area, the division was struggling to meet mounting service demands, with two-thirds of its order lines requiring express processing to ensure next-day delivery. This intense requirement placed substantial pressure on the smooth operation of the Central Distribution Center (CDC), which employs over 300 blue-collar workers.

Challenge: The existing patchwork warehouse structure, consisting of multiple facilities within a small region presented a substantial challenge. Especially for storage system optimization, automation, resource allocation, and process standardization. Functional areas had to be duplicated across locations, increasing operational redundancy and complexity. Moreover, the necessity for high-frequent inter-facility transportation not only escalated transport efforts but also amplified logistics costs and coordination efforts. This setup severely hindered the effective utilization of workforce and equipment, compounding inefficiencies and impacting overall service delivery.

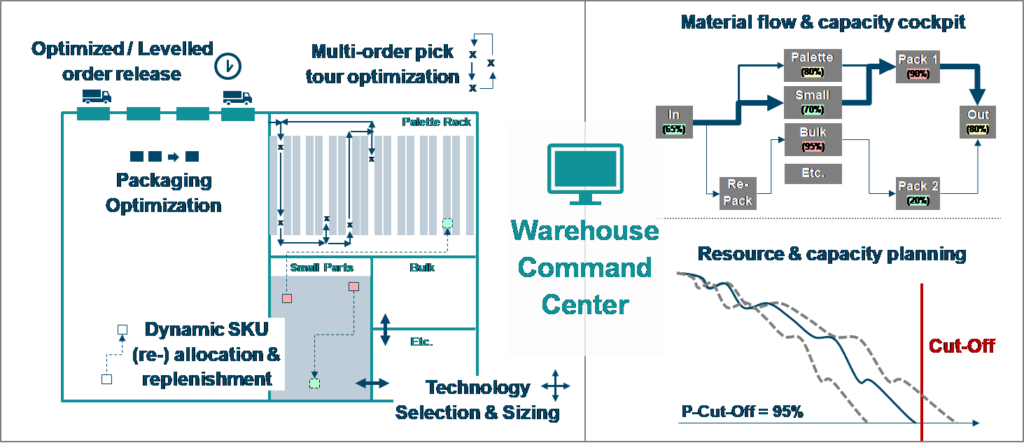

Strategic analysis: The leadership team initiated a comprehensive study to enhance transparency across warehouse operations and pinpoint key areas for improvement. This strategic analysis delved into every aspect of the warehouse process, from inbound logistics and re-packaging to binning, warehousing, picking, packing, and shipping. To support this analysis, a robust planning database was established, incorporating a wide range of data points essential for a thorough evaluation. This included both quantitative data such as inbound and outbound logistics transactions, intercompany transactions, SKU master data, inventory levels over time, and storage locations within the warehouse, etc. Additionally, qualitative data was also integrated, covering process productivities, warehouse layouts, operational areas, stakeholder feedback, etc.

The insights derived from this multifaceted analysis proved crucial in crafting a strategic roadmap tailored to drive significant enhancements in warehouse operations. By systematically analyzing these diverse data streams, the leadership team was able to identify inefficiencies, streamline processes, and ultimately set a course for future operational success, ensuring that the warehouse could meet evolving business demands and market conditions.

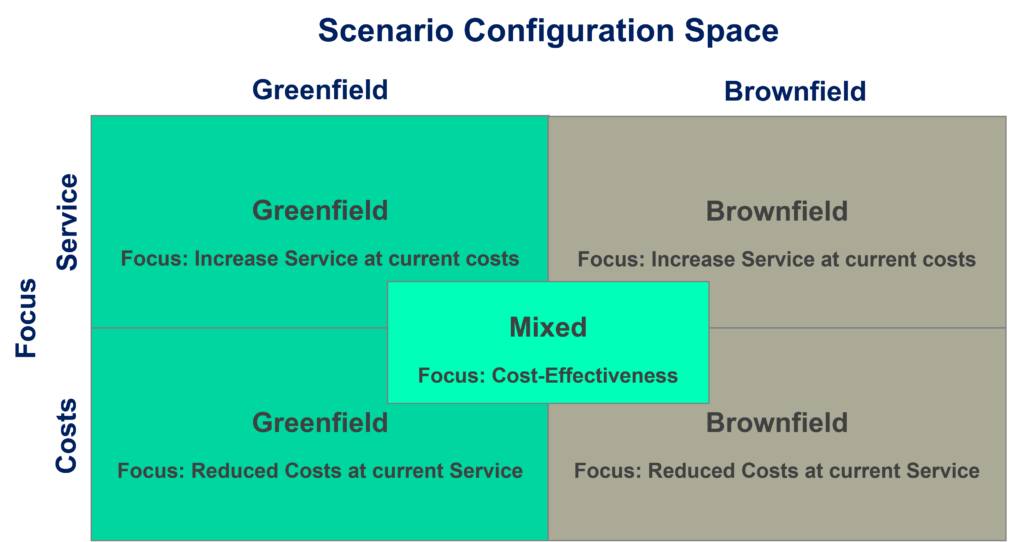

Scenario planning & strategic outcomes: Using a digital twin for the warehouse, multiple opportunities for operational improvements were identified across the warehouse operations. These ranged from tactical adjustments to strategic overhauls, each varying in scope, cost, and return on investment. Immediate improvements with short-term returns were promptly addressed. For instance, the implementation of small parts automation and the integration of automated packaging lines were recognized as “quick wins” that could swiftly enhance efficiency and reduce labor costs. These solutions not only promised rapid returns on investment but also offered significant improvements in daily operations.

On the other hand, some identified improvements were of a more strategic nature, necessitating a long-term outlook and substantial investments. Most of these levers required to again concentrate voperations in one central location which, while costly and requiring more extensive planning and implementation, were projected to fundamentally transform operations and yield substantial benefits over time. The scenario planning thus provided a balanced roadmap, enabling the company to address immediate inefficiencies while also setting the stage for sustained, long-term operational success.

Short/ medium term implementation: Derived from the analysis enabled by the digital twin of the warehouse operation, several elements were prioritized as quick wins:

- Improved reporting & transparency: The adoption of continuous automated reporting systems has introduced unprecedented visibility into warehouse operations. This new level of detail serves as the foundational planning base for the strategic components of the roadmap, facilitating more informed decision-making and future planning.

- Automated packaging line: The development of a business case for an automated packaging line revealed substantial benefits. This initiative is projected to significantly reduce the need for personnel and promises a rapid return on investment (ROI) within less than two years.

- Automated small parts area: The small parts segment, critical for maintaining high service levels, was subject to a comprehensive evaluation through simulation and business case analysis. The decision to invest in advanced automation technology for this area is anticipated to elevate next-day service levels by multiple percentage points. Moreover, this investment will reduce the headcount numbers, while achieving an attractive ROI within 2-3 years.

Strategic Initiative: Leveraging insights from the digital twin model, a business case for centralizing warehouse operations was developed. The evaluation showed that despite requiring substantial upfront investment, the potential long-term benefits justified this decision. Currently the centralization is proceeding as planned, integrating and updating the model as circumstances change.

Self-assessment for data-driven culture

Achieving transparency and visibility is fundamental to evolving into a data-driven supply chain culture, focusing on explanatory relationships, evidence-based reasoning, and rapid feedback loops. But what does this mean and how is my current performance level?

A practical method to assess your current capabilities involves examining the time required to compile an analysis of the previous month’s supply chain costs and performance figures. This analysis should be detailed, categorized by cost types, and linked directly to causal factors, providing clear insights into operational dynamics.

Consider the following examples as benchmarks for your supply chain analytics capabilities. Are you able to identify and address issues like these:

- Transportation Costs Analysis: e.g. Road transport costs increased for a specific location by X% while volumes decreased by Y% leading to a significant increase of the cost per volume relationship. Is this a one-time thing or the beginning of a lasting shift in the customer order pattern, which requires you to deploy countermeasures?

- Inventory Coverage Analysis: e.g. Inventory coverage of a SKU-group decreased significantly in a specific DC by X% while outbound volumes and forecast accuracy remain stable, decreasing capital cost or working capital impact for this month. But is the coverage still sufficient or will there be a spike of express shipments next month?

- DC Analysis: e.g. Value and volume per customer order has decreased continuously throughout the last 10 months in almost all DC’s, increasing the DC productivity on a time per order basis, because on average the smaller orders can be picked faster. At the same time this decreases the revenue per pick, leading to an overall increase of the required DC personnel to handle the same revenues. Can we deploy short-term counter measures aligned with sales to incentivize customer to increase order volume again or do we have to rethink our picking processes and technology because the trend is likely to continue due to strongly increasing B2C business?

Useful Example Questions for Assessment

- Data availability: Do you have access to real-time and historical cost and transaction data that allows for structural analysis?

- Data integration: Can you integrate real-time data with historical and forecast metrics to analyze trends and predict future needs?

- Predictive analytics: Are your systems equipped to use predictive modeling to forecast potential stock-outs or the need for express shipments based on current inventory levels and sales forecasts?

- Analytical tools: Are your current tools capable of performing classical analytics questions such as optimization, simulation, and forecasting?

- Decision speed: How quickly can your analytics team generate insights from this data, and are these insights timely enough to influence decision-making effectively?

- Strategic response capability: Based on the analysis, can your team swiftly develop and deploy countermeasures, such as adjusting transportation routes, modifying supply chain strategies, adjusting inventory policies, renegotiating terms with transport providers, etc.?

If your organization can effortlessly survey its supply chain with a single click, it signifies that you have achieved an exceptional level of transparency and capability. This foundational transparency is crucial as it allows for the strategic tuning of your supply chain, further automation of processes, and orchestration of the entire end-to-end supply chain network.

Transformation through transparency

The transformational impact of achieving data-driven transparency in supply chain operations cannot be overstated, as demonstrated in the case studies discussed. Transparency acts as a catalyst, enabling rapid shifts towards more dynamic systems capable of quickly adapting to changing conditions and challenges.

Litmus test for supply chain transparency

To gauge whether your supply chain possesses the necessary transparency to become dynamic, consider whether you can swiftly compile a detailed analysis of last month’s supply chain costs and performance. This analysis should go beyond superficial metrics, such as a high-level “supply chain cost per revenue ratio,” and instead delve into the causal relationships between costs and performance. A truly transparent supply chain allows for quick identification of issues and has the capabilities to resolve them at the neccessary levels of detail.

If identifying and addressing issues requires exhaustive analysis each time a KPI fluctuates, your supply chain will likely remain static—too slow in its error correction and adaptation processes to effect meaningful change. In contrast, a dynamic data-driven supply chain equipped with robust analytics can swiftly navigate challenges, turning potential disruptions into opportunities for enhancement.

The Expert

Partner Consulting | Siemens Digital Logistics

Want to learn more?

Contact Siemens Digital Logistics today to discuss how our solutions can help your business thrive in the face of these new regulations. Learn more about our Consulting services.

Read Part one: The power of insight: Rethinking supply chain decision making – part 1

More information

Contact us (select “Digital Logistics” as Product)