Vulnerable supply chains in the consumer goods industry: Why resilience starts with design

The consumer goods industry has always been defined by complexity. From smartphones and apparel to home and DIY products, companies depend on globally sourced materials and highly fragmented supply networks. This global exposure makes the sector particularly vulnerable to disruption – whether from geopolitical events, regulatory changes, climate-related crises or shifting consumer demands.

Download the infographic “Vulnerable supply chains in the consumer goods industry“, that highlights the scale of these challenges and the strategies companies are adopting to address them.

Global exposure, local impact

Consumer goods manufacturers source critical materials – such as lithium, cobalt, indium or gallium – from across the globe. This creates risk: a disruption in a single supplier country can ripple across entire value chains. According to recent industry surveys, nearly 85% of organizations experience unplanned downtimes linked to supply chain issues, driving up costs and impacting customer satisfaction.

Trade disputes are also an escalating concern. They are ranked as the top geopolitical threat for consumer goods companies, underscoring the need for strategies that can withstand sudden market shifts.

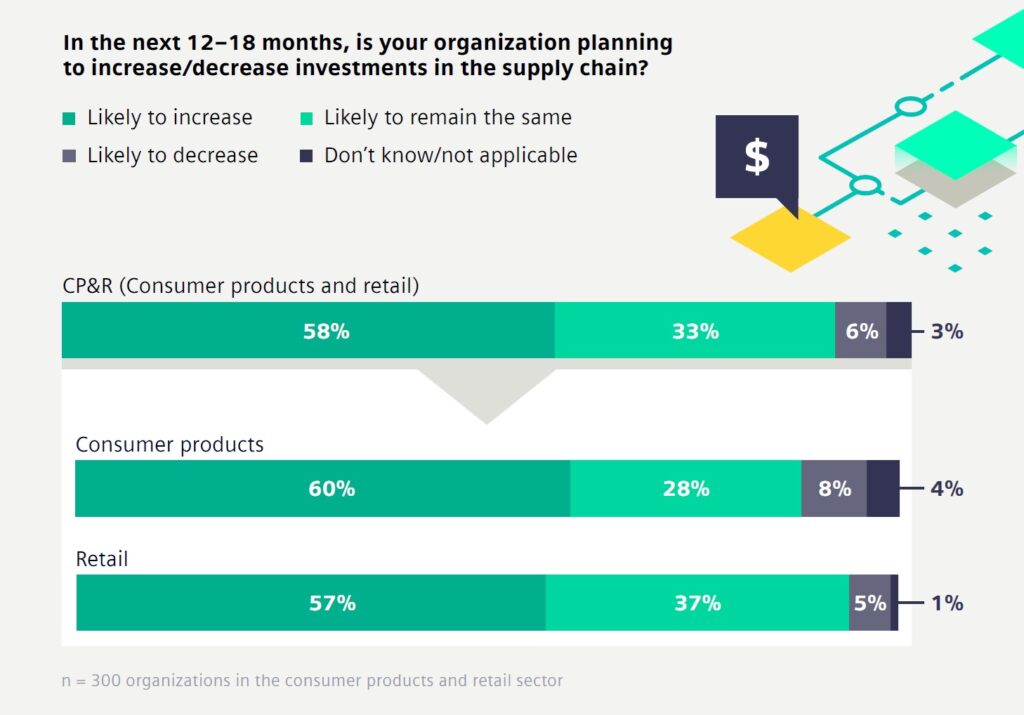

Shifting supply chain priorities

The industry is responding with a clear focus on resilience and agility. In the consumer products and retail sector:

- 79% of organizations are diversifying their supplier base.

- 71% are investing in regionalization and localization.

- 83% are adopting “friendshoring” strategies to reduce geopolitical exposure.

At the same time, companies are increasingly committed to sustainability targets and exploring models such as nearshoring and the circular economy. Digital transformation plays a central role, with technologies like AI and predictive analytics enabling faster response to disruptions and greater transparency across the value chain.

From “design for product” to “design for supply chain”

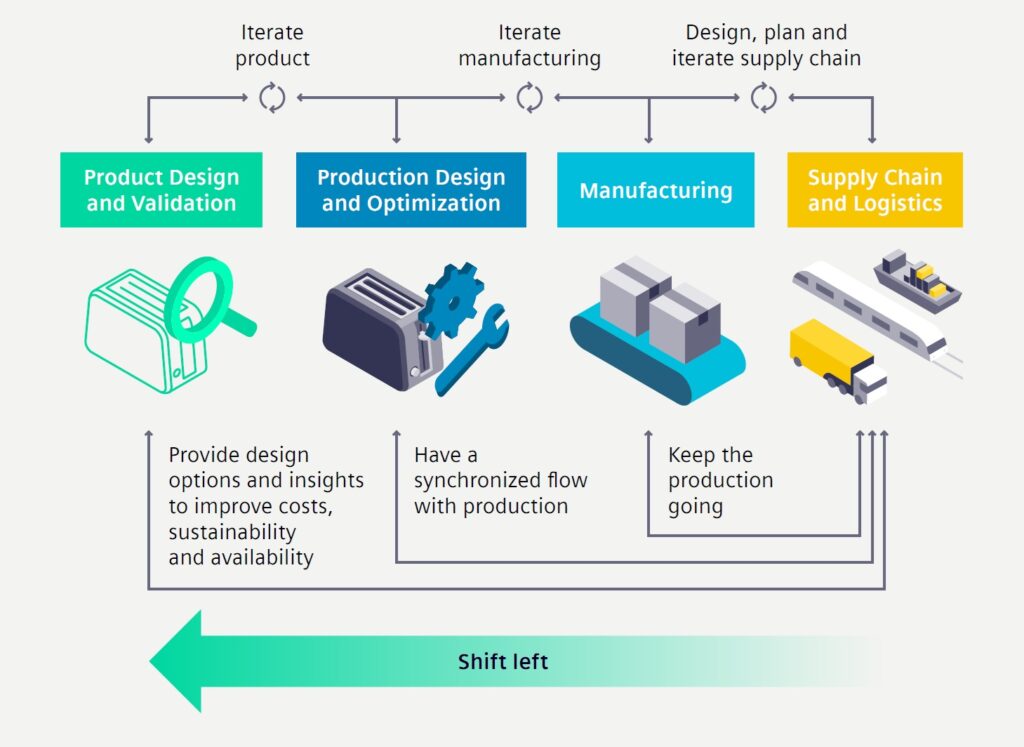

Building resilient supply chains requires a shift in perspective. Traditional supply chain planning often starts too late – reacting to issues rather than anticipating them. A “shift-left” approach integrates supply chain considerations at the earliest stages of product design.

By extending the digital twin to include a supply chain dimension, organizations can evaluate trade-offs between cost, risk, sustainability and quality from the start. For example, embedding cost and carbon footprint calculations into the product lifecycle ensures consumer goods are both economically viable and environmentally responsible.

Enabling resilient consumer goods supply chains

Siemens Digital Industries Software helps consumer goods companies move from reactive to proactive supply chain management. By linking product design, production and logistics in a single digital environment, businesses gain the visibility and insights needed to balance performance, efficiency and resilience.

To learn more, explore our infographic “Vulnerable supply chains in the consumer goods industry“. And for a deeper dive into how the shift-left approach can help you strengthen your supply chains, download our white paper “The shift-left logistics imperative”.