Enterprise recipe management & comprehensive digital specification for food and beverage: The Formula for Success

The act of mixing ingredients based on a recipe is quite simple.

The difficult part is scaling that recipe up and mass producing it in a way that it maintains its quality and taste. This is the real challenge as it involves determining where to produce a new product, in what quantities and whether they should move existing ones to a new plant to accommodate the mixing and packaging. These decisions are based on various business requirements, such as proximity to market, transportation costs, regulatory compliance and demand.

To scale up or move a recipe from one existing plant to another can take up to six months, and even then, the result may be that you can’t even manufacture the product or fill the package at that plant.

How can you streamline and optimize operations so that a small-batch formula can scale to the manufacturing level?

Using digitalization to scale up

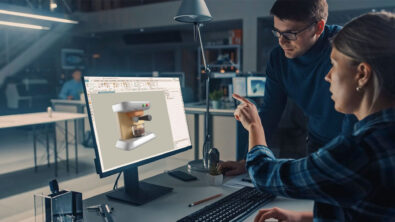

A fast scale-up to manufacturing has been achieved in other industries, such as automotive, aerospace and consumer electronics where digitalization is revolutionizing how products are designed, manufactured and optimized.

However, the food and beverage industry is trickier because it’s subject to greater variability of products and larger portfolios that brings complications when scaling up for production.

What is driving the complexity in the food and beverage industry?

- Consumers’ changing tastes and trends

- Allergen/dietary considerations

- Product quality

- Transparency in sourcing

- Glocalization

- Sustainable manufacturing practices

- Government regulations

When it can take anywhere from six months to five years to develop a new recipe, having the agility to make this product when and where you need to is imperative. But the scaling up process from the lab to the production line can add months after you’ve developed the recipe.

Even then, it’s not guaranteed to work.

But it can.

Implement digitization in all stages of the recipe development process

Digitalization provides greater consistency, speed and efficiency when scaling up from your formula to a general recipe and ensuring it aligns with the manufacturing process.

Enterprise Recipe Management tackles the issues of consumer goods manufacturers having to use ingredients that differ from their original formula, using equipment that must create at scale or operate a plant that may have different equipment than initially intended.

Regardless of these complexities, the product results must be consistent to protect brand equity and the ultimate promise to the consumer.

The use of manufacturing process configuration and validation tools reduces the time it takes to implement a recipe change based on equipment, plant and resources modifications from months to seconds.

How a cold brew coffee company finds the recipe for success

Comprehensive digital specification is part of Siemens’ Enterprise Recipe Management software solutions can directly integrate product formulation, laboratory testing and recipe designers into the production execution world in seconds. It’s a way to go from manual to digital, optimize operations, find better use of raw materials and ensure that your recipe maintains a high-quality standard wherever it’s mixed.

Let’s take a look at how a cold brew coffee company might go about introducing a vegan option to their portfolio and help create their new formula and guarantee plant production capability using comprehensive digital specification solutions.

In this example, the coffee cold brew company is creating a new formula similar to their current latte cold brew. This new recipe consists of a cocoa and rice powder as a vegan alternative so the development team must modify the formula. Once the recipe is designed:

- The lab can test and analyze the new recipe as it goes through several iterations before it gets the formula right.

- A General Recipe is generated where redundant processes are selected and requirements are implemented into the production plan. For instance, the previously developed process for the grinding and roasting of the coffee can remain the same.

- The powdered flavors are placed in the pre-mix for the production line where pre-defined transformation rules will automatically update the process when a switch from latte to rice/cocoa is necessary.

- Any switching to accommodate demand is implemented quickly and automatically.

Going from manual to digital

As you can see in the cold brew example, the results are immediately realized in the initial stage of Enterprise Recipe Management making the transition between formulation and General Recipe creation smoother.

What once took months to create a suitable formula based on several plant and equipment factors, food and beverage companies can complete in seconds.

- Recipe Formulation. Track product material swapping when moving from design to formulation, so you know what’s been added or removed. This will also develop the plant formula based on production engineering inputs.

- Simulation. Via simulation, the formula runs through various plant conditions to understand critical product behavior.

- Machine Learning. Along with simulation, you’ll have data-driven analysis of the plant equipment performance.

- IIoT, MES, PFC and Automation. These advanced technologies monitor power quality and equipment usage as well as tracking equipment behavior at crucial points in the process for maximum performance and equipment efficiency.

Comprehensive digital specifications

Digitalization helps adjust recipes and formulas based on consumer demands and manufacturing capabilities and can even help shift operations to a more direct-to-consumer model.

Comprehensive digital specification means:

- Nimble to react to market trends

- Fast to test new ideas, concepts, ingredients and substitutions

- Changing sourcing preferences and profitability at large scale

- Scaling up anywhere

Design and optimize your formula with comprehensive digital specifications solutions from Siemens.

Explore more insights—visit our resource page today.