The next transformative force of innovation, efficiency, and sustainability has arrived

The Importance of Integrated Lifecycle Management in food & beverage

The food and beverage industry is undergoing a dramatic transformation, driven by evolving consumer tastes, more restrictive regulatory environments, increasingly complex supply chains and heightened concerns about sustainability. Changes in these areas require more than gradual improvements—they require fundamental reinvention of product development, production and delivery. At the center of this change, digital transformation presents both a challenge and a powerful enabler, shaping a whole new core of manufacturing processes and Product Lifecycle Management (PLM).

Here, Siemens’ Integrated Lifecycle Management (ILM) steps in—not as a pure add-on of technology, but as a strategic enabler. ILM integrates portfolio and product lifecycle management capabilities, forging a holistic approach that increases agility, ensures compliance, and drives resource efficiency. This is not about embracing a new array of digital tools for food and beverage companies; it’s about becoming resilient, enhancing product integrity, and bringing up the pace of innovation.

As we dive deeper, we’ll explore how ILM facilitates this journey, offering insights into how companies can realign their operations to thrive amid the industry’s current challenges and capitalize on emerging opportunities.

Digital strategy and execution with ILM’s digital charter

A successful digital transformation in the food and beverage sector starts with a clear strategy. ILM’s digital charter provides a structured framework through which technology investments are made by aligning with strategic objectives-assuring that every digital initiative meaningfully contributes toward overall business objectives. Key benefits of a digital charter include:

- Comprehensive strategy: It outlines the long-term vision for digital transformation, identifying key areas for digital integration and setting measurable objectives.

- Enhanced coordination: By offering a unified roadmap, the Digital Charter helps synchronize efforts across departments, ensuring that digital initiatives are harmonized and goal-focused.

- Proactive risk management: Early identification of potential digital risks allows for the formulation of mitigation strategies, minimizing disruptions to the manufacturing process and safeguarding against data breaches or technology failures.

The Digital Charter isn’t just documentation; it’s the foundational DNA of a forward-thinking manufacturing enterprise, embedding strategic, digitally-driven innovation into the company’s core operations.

Agile responses to market demands: Mastering plan execution

Agility is key in a sector where seasonal trends, ingredient availability, and regulatory changes can rapidly alter production needs. ILM’s Plan Execution capabilities empower teams to rapidly adjust operations, delivering products that consistently meet quality and safety standards, even as external conditions shift. With ILM:

- Dynamic Planning and Scheduling: Real-time optimization of production schedules ensures efficient resource usage, preventing wasted ingredients and helping maintain freshness standards.

- Real-Time Project Monitoring: Gain instant visibility into supply chains, production lines, and quality metrics, enabling quick adjustments to maintain product integrity and meet evolving consumer demands.

- Collaborative Workspaces: Connect teams across geographical and organizational boundaries, for faster decision-making, improved communication and unified responses to the changes happening within the marketplace.

Agility in plan execution isn’t just about staying competitive; it’s about making sure products reach consumers at peak quality, taste, and safety—every single time.

Specification management: Ensuring precision and quality

For food and beverage products, precision in formulation and strict adherence to specifications is non-negotiable. Specification Management within ILM secures a single, trusted repository for all product data, ensuring absolute consistency, safety, and compliance. Benefits include:

- Single Source of Truth for Specifications: Store ingredient lists, nutritional values, packaging requirements, and labeling standards in one place that is easily accessible to all.

- Automate Compliance Checks: Automate safety regulations, allergen controls, and regional labeling laws to reduce manual oversight and speed time-to-market.

- Intellectual Property Protection: Protect proprietary recipes, flavor profiles, and formulations while maintaining competitive advantage by ensuring only authorized personnel can access sensitive data.

When specifications are seamlessly managed, new product launches become faster, safer, and more aligned with consumer expectations and regulatory obligations.

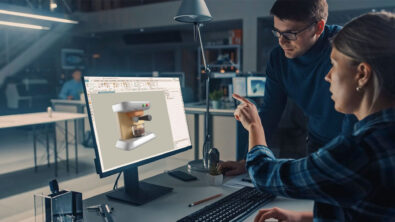

Integrated lifecycle management: a single source of information and streamlined process for managing all aspects of the product from concept to end-of-life

Embracing a sustainable future in food & beverage manufacturing with Siemens ILM

Sustainability is quickly becoming the hallmark modern food and beverage companies today. ILM doesn’t simply optimize existing operations; it infuses sustainable thinking at every stage of the product lifecycle. By leveraging advanced analytics and integrated data, ILM empowers manufacturers to:

- Reduce waste by fine-tuning production runs and resource usage to minimize excess ingredients, packaging materials, and energy use

- Perform detailed lifecycle assessments, gaining insights into the environmental impact of raw materials, production processes, and distribution channels

- Adopt sustainable design principles, enhancing product integrity while minimizing ecological footprints and supporting regenerative supply chain practices

With ILM, sustainability isn’t an afterthought or an ideal—it’s a measurable, strategic advantage. As consumers demand more environmental accountability, embracing ILM helps ensure your company not only adapts to the changing landscape but is also setting new industry standards for responsible professional practice.

Shape the future of manufacturing—Today

The food and beverage industry’s evolution is ongoing and inevitable. With Siemens Integrated Lifecycle Management, your organization doesn’t just keep pace; it leads the charge—crafting a future where innovation, efficiency and sustainability converge.

Ready to learn more?

Check out this webinar and discover how ILM can transform your operations today.