The future of CPG manufacturing: flexible, predictive, and sustainable – interview

The consumer packaged goods (CPG) industry is at a crossroads. Rapidly changing consumer preferences, particularly around healthier and more sustainable products, combined with rising raw material costs, are forcing manufacturers to rethink how they operate. Traditional production models are no longer enough to meet these evolving demands. To stay ahead, companies must embrace more flexible and predictive manufacturing approaches that allow them to adapt quickly and remain competitive.

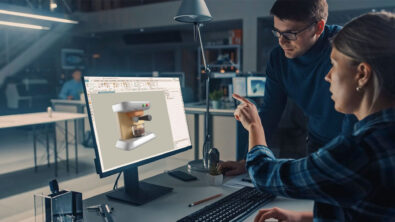

Digital twin: a game-changer for manufacturing

At the core of this shift is the implementation of digital twin technology. The digital twin acts as a virtual representation of the product, production process, and entire supply chain, providing manufacturers with real-time insights and the ability to simulate various scenarios. This allows for quick adjustments to production lines, better inventory management, and seamless coordination across different stages of manufacturing.

By utilizing data analytics, companies can not only optimize operations but also predict changes in demand or supply chain disruptions. This level of agility helps manufacturers minimize costs, reduce waste, and ensure high-quality production, even in the face of fluctuating market conditions.

Predictive maintenance for operational and environmental benefits

Another crucial factor in the digital transformation of CPG manufacturing is predictive maintenance. By using sensors and data analysis, manufacturers can detect potential issues with machinery before they lead to breakdowns, significantly reducing downtime. Beyond improving operational efficiency, predictive maintenance also supports sustainability goals. Early detection of machine anomalies helps minimize energy waste and prolong the lifespan of equipment, making operations more eco-friendly and cost-effective. Predictive algorithms can flag issues like overheating motors, enabling timely interventions that prevent larger, more expensive problems down the line. This proactive approach to maintenance not only improves machine performance but also contributes to a greener production environment by reducing energy consumption.

Low-code platforms and customization in manufacturing

Low-code platforms are becoming an essential tool for CPG manufacturers as they provide the ability to customize and reconfigure production workflows with ease. This flexibility is vital in an industry where consumer demands can shift rapidly. By integrating low-code solutions, manufacturers can tailor their operations to specific product requirements, streamline collaboration between teams, and adapt faster to market needs. These platforms also support scalability, enabling manufacturers to produce innovative and personalized products in varying lot sizes while maintaining efficiency and cost control. This level of agility ensures that companies can stay competitive in a dynamic marketplace.

The power of IT-OT integration for continuous improvement

A key enabler of long-term success in the CPG industry is the integration of information technology (IT) and operational technology (OT). By combining data from these two areas, manufacturers can create a more holistic and data-driven approach to decision-making. IT-OT integration helps companies optimize their processes, drive continuous improvement, and enhance their sustainability efforts by reducing energy consumption and improving resource management. This integration also lays the foundation for continuous improvement in operations, allowing manufacturers to make incremental enhancements over time rather than relying on one-off solutions. It supports more agile production models and contributes to greater overall efficiency.

For more detailed insights into these transformative strategies, watch the full interview featuring Cheyenne Goeminne, Industry Marketing Manager and Kevin Hoorne, Industry Manager from Siemens Digital Industry Software, where they delve into the digital tools reshaping CPG manufacturing and discuss how companies can navigate the challenges of today’s market.