7 key strategies for production traceability and supply chain resilience in consumer products and retail

Production traceability has become a cornerstone in the modern supply chains of the consumer products and retail (CP&R) sector. As the industry faces unprecedented challenges and exciting opportunities, production traceability alongside sustainability, resilience and digital transformation is driving the future of supply chain management. These elements have become essential pillars of modern supply chain management. Let’s explore seven key strategies that are reshaping the future of CP&R supply chains.

1. Prioritizing resilience and production traceability in supply chains

In today’s unpredictable global market, resilience has become an essential component of supply chain management. The CP&R sector, characterized by fluctuating consumer demands and external disruptions, requires supply chains that can quickly adapt and recover. This resilience ensures business continuity, protects revenue, and maintains customer trust. In an industry where change is constant, building resilient supply chains is not just a strategy—it’s a necessity for sustainable growth. An integral part of this resilience is production traceability, which allows companies to monitor and adapt their operations in real-time, reducing risks associated with disruptions.

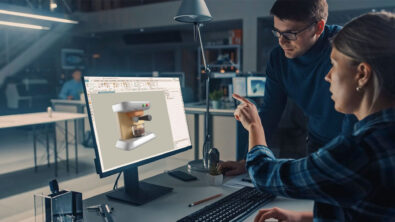

2. Digital transformation: The engine behind sustainable logistics

Digital transformation, driven by technologies like edge computing and artificial intelligence in manufacturing, is a critical enabler for achieving sustainability in logistics. By integrating advanced technologies, companies can access real-time data from across their supply chains, including consumer packaged goods analytics. This enhanced visibility allows for smarter decision-making, optimizing logistics processes, reducing waste, and lowering energy consumption. However, digital transformation is more than just adopting new technologies; it’s about rethinking traditional processes to create logistics strategies that are both efficient and environmentally responsible.

3. Leveraging digital platforms for sustainable operations

Digital platforms are becoming indispensable tools in the drive toward sustainable logistics. These platforms provide a unified environment for managing all aspects of supply chain operations, from procurement to customer delivery. By enabling real-time monitoring and data analytics, including CPG analytics solutions, digital platforms support sustainable practices, such as optimizing delivery routes and reducing carbon footprints. This integration is crucial for companies aiming to meet their sustainability goals.

4. Transparency: The cornerstone of green logistics

Transparency is vital for any green logistics strategy. It allows companies to monitor and measure their sustainability initiatives effectively. A transparent supply chain extends beyond internal operations to include collaborations with external partners and suppliers. This comprehensive approach enables companies to better control their environmental impact throughout the supply chain, ultimately leading to more sustainable operations and stronger consumer trust. Implementing production traceability systems is a critical step in achieving this level of transparency.

5. Integrating traceability and lifecycle intelligence

As the CP&R industry continues to evolve, the integration of traceability and lifecycle intelligence offers a powerful approach to supply chain management. This integration enhances flexibility, allowing companies to adapt to changing market demands more quickly. Key dimensions of this approach include:

- Manufacturing Intelligence: Reducing production downtimes through real-time insights.

- Product Performance Intelligence: Enhancing consumer experiences by leveraging data-driven insights.

- Trusted Traceability: Building brand loyalty by ensuring transparency and accountability throughout the product lifecycle, which can be facilitated by advanced CPG analytics solutions.

6. The role of Siemens Xcelerator in digital transformation

Siemens Xcelerator plays a crucial role in accelerating digital transformation within the CP&R sector. This open digital business platform provides companies with the tools needed to scale their digital initiatives and establish a robust foundation across the product lifecycle. By leveraging Siemens Xcelerator, companies can adapt more effectively to the dynamic market environment, ensuring they remain competitive and responsive to consumer needs, particularly by enhancing their consumer packaged goods analytics capabilities.

7. Converging sustainability, resilience and digital transformation

The CP&R industry is at a transformative intersection where sustainability, resilience, and digital transformation converge. By focusing on these key elements and integrating advanced solutions like production traceability and CPG analytics solutions, companies can significantly enhance their operational efficiency while making meaningful contributions to sustainability. This comprehensive approach not only positions companies as industry leaders but also underscores the importance of balancing agility with environmental responsibility for long-term success.

Strategic takeaways

These seven strategies illustrate the critical role that production traceability, sustainability, resilience, and digital transformation play in shaping the future of CP&R supply chains. By embracing these approaches, companies can navigate the complexities of the modern business landscape and emerge as leaders in an increasingly competitive industry.

How will your organization integrate these strategies, particularly in the areas of production traceability and consumer packaged goods analytics, to stay ahead in the rapidly evolving CP&R sector?