Overcoming EV and AV complexity with model-based systems engineering

Discover how generative design and advanced automation can revolutionize your vehicle architecture

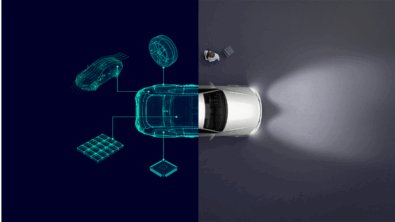

The rapid advancements in electric vehicle (EV) and autonomous vehicle (AV) technologies are introducing unprecedented levels of complexity into vehicle architecture. This surge in complexity is challenging traditional development methods, demanding new approaches to design, engineering, and manufacturing.

Integrating countless sensors, intricate software systems, and advanced hardware components into a single vehicle creates a tangled web of challenges. From managing the sheer volume of data to ensuring seamless interactions between different systems, automotive manufacturers are grappling with a perfect storm of complexities.

The traditional, siloed approach to vehicle development is no longer sufficient to meet the demands of this new era.

The industry is turning to innovative solutions to navigate this complex landscape. Model-based systems engineering (MBSE) and generative design are emerging as powerful tools to address these challenges.

These technologies can streamline development, reduce errors, and accelerate time-to-market by providing a holistic view of the vehicle and automating many design processes.

In this blog, we will delve deeper into the complexities of EV and AV development, explore the limitations of traditional methods, and uncover how MBSE and generative design can be leveraged to drive innovation and efficiency in the automotive industry.

The growing complexity of EV and AV development

Integrating advanced software, an expanding array of sensors, and novel hardware components into EVs and AVs presents significant challenges for traditional design and development processes.

Engineers are grappling with integrating these new technologies into existing vehicle architectures, which are already overburdened with modules, ECUs, harnesses, and wiring.

The sheer volume of components adds weight to vehicles and creates a complex web of interactions that are difficult to manage and optimize. Moreover, the software-driven nature of modern vehicles is accelerating at an unprecedented pace, with lines of code multiplying exponentially.

This surge in software complexity is compounded by the criticality of ensuring bug-free performance, as issues in automotive software can have severe consequences.

Model-based systems engineering (MBSE) and generative design are emerging as potential solutions to address these challenges by providing a framework for system-level design, optimization, and automation.

Traditional development methodologies, characterized by siloed teams and manual processes, need to be equipped to handle this level of complexity. The industry increasingly recognizes the need for a holistic approach to effectively manage the interplay between software, hardware, and electrical systems.

Understanding the role of MBSE in overcoming complexity

To address the challenges of complexity in vehicle architecture, MBSE is emerging as a critical approach.

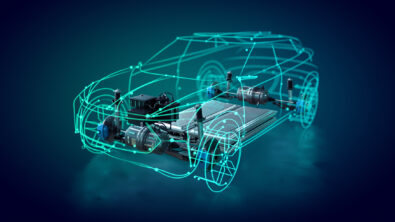

MBSE is a systematic approach to engineering complex systems using models as the primary means of communication and analysis. By creating a digital representation of the entire vehicle system, MBSE enables a holistic view, allowing engineers to understand the intricate interactions between different components and subsystems.

A cornerstone of MBSE is the use of functional models.

These models represent the desired behavior of the vehicle system without specifying the underlying hardware or software implementation. By integrating functional models into the vehicle architecture, engineers can explore different design options, assess trade-offs, and optimize the system for performance, cost, and safety. This model-based approach fosters collaboration among different engineering disciplines, breaks down silos, and accelerates the development process.

MBSE empowers teams to leverage generative design techniques as well. By defining design parameters and constraints, engineers can generate multiple design alternatives, allowing them to identify optimal solutions more efficiently.

This iterative process enables continuous improvement and innovation throughout the vehicle lifecycle.

By adopting MBSE, automotive manufacturers can effectively manage the increasing complexity of EVs and AVs, reduce development costs, and accelerate time-to-market.

The power of generative design

Generative design is a powerful tool that harnesses the potential of model-based engineering to revolutionize the development process.

It is essentially an algorithmic process that explores multiple design solutions based on defined parameters and constraints. In the context of vehicle development, it can be applied to optimize everything from individual components to the overall vehicle architecture.

By rapidly generating and evaluating countless design variations, engineers can identify optimal solutions that meet performance, weight, cost, and other critical objectives.

The benefits of generative design are far-reaching. It accelerates development cycles by automating routine tasks and enabling engineers to focus on higher-level design decisions.

Generative design enhances vehicle design by optimizing architecture and components, resulting in lighter, more fuel-efficient, and safer vehicles. For EVs, this technology can maximize battery range and charging speed. And generative design contributes to creating more robust and dependable sensor systems in developing AVs.

Ultimately, generative design is poised to become a cornerstone of future vehicle development, enabling manufacturers to create next-generation EVs and AVs that are not only technologically advanced but also sustainable and cost-effective.

Overcoming key challenges in AV and EV development

Integration, time-to-market pressures, and the sheer volume of data are straining traditional development methods. A paradigm shift towards MBSE and generative design is essential to address these hurdles.

MBSE provides a structured approach to managing the complexity inherent in EV and AV development. By creating a digital twin of the vehicle, engineers can simulate and analyze various design scenarios, accelerating development and reducing costly physical prototypes.

MBSE’s generative design capabilities explore multiple design options, optimizing vehicle architecture for enhanced performance, efficiency, and safety.

For instance, by leveraging MBSE and generative design, automotive manufacturers can optimize vehicle architecture for both electric propulsion and autonomous functionalities.

This holistic approach identifies synergies between different vehicle systems, leading to improved efficiency, reduced weight, and enhanced performance. That makes it possible for engineers to significantly improve electric vehicle range and charging speed by applying generative design to battery packs, thermal management systems, and sensor placement.

By embracing MBSE and generative design, the automotive industry can overcome the complexities of EV and AV development, accelerate time-to-market, and deliver innovative, high-quality vehicles that meet future demands.

Reimagining vehicle architecture with MBSE and generative design

The automotive industry is undergoing a transformative shift driven by the rapid adoption of EVs and AVs. This evolution introduces unprecedented complexity, demanding innovative approaches to vehicle architecture.

By embracing MBSE, engineers can establish a unified digital thread, connecting requirements, functional designs, and physical components. This holistic approach fosters collaboration across disciplines, accelerates development cycles, and ensures product quality.

On the other hand, generative design unleashes creativity by exploring countless design possibilities and optimizing for performance, weight, and cost.

Together, MBSE and generative design empower organizations to create future-proof vehicle architectures. By shifting left and focusing on system-level thinking, engineers can make informed decisions early in development.

This proactive approach mitigates risks, reduces costs, and accelerates time-to-market.

Are you ready to unlock the full potential of your vehicle development process? Watch the entire webinar and explore our resources to learn more about implementing MBSE and generative design in your automotive development.