The process of innovation: Then and now – Synthetic force fields as a worked example: Part 2

As a mechanical engineer, I kind of get SDFs (signed distance fields), a field beyond or within an object’s boundaries whose strength and sign are proportional to the distance from that object’s boundary. My innovation concept was maybe if that SDF was considered as a force field then it might be used to attract or repel neighbouring 2D objects so as to identify an optimal tessellation of N given 2D shapes.

That’s all I had as an innovation starting point, but with the recognition that I had close to zero coding expertise to be able to investigate such a 2D shape tessellation method myself without a LOT of help. Prior to ChatGPT’s initial release on Nov 30 2022 I would have given up. Now 3 years later I’ve achieved an innovation goal in a matter of hours that would have been unimaginable just a few years prior.

An LLM as more than a chat buddy

Let’s start at the end of my LLM enabled innovation story. Here an animation of the final refined method that uses innovative SDFFs (signed distance force fields) to consider collocated 9 Squares and 19 Circles, then to have them ‘shuffled around’, adhering to their attractive and repulsive force fields until such time as they all tessellate. Allowance made for overlapping shapes prior to them tessellating, with forces imposed to repel on an overlap and attract on a separation.

How it all started

After an initial couple of setting the scene prompts with my favourite LLM, this was my seminal prompt that I asked it:

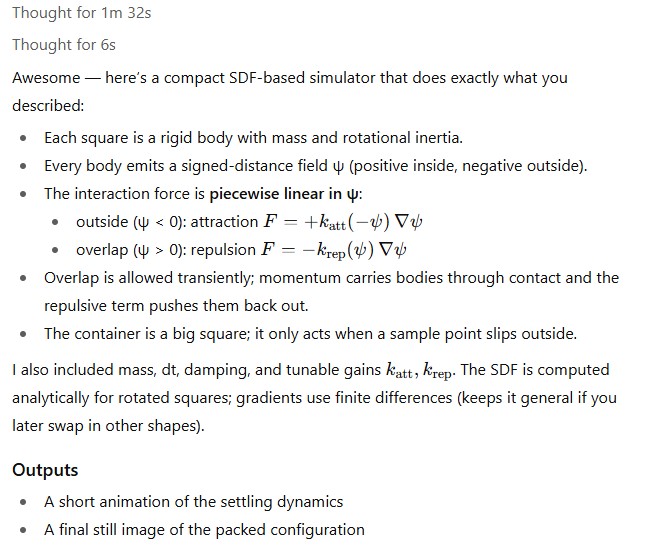

“I think the use of SDFs would be the way to go. +ve values (i.e. outside) attract, -ve values (i.e. inside) repel. Each shape should have a mass and inertia should be accommodated. The only ‘knobs’ to vary would be the mass of each shape, the dt time step considered then, most importantly, the force field strength as a function of the SDF value (maybe a linear piecewise definition would be good). I’ll leave it to you to propose the initial Force=f(SDF)! Can you generate the Python for me and some form of visual output?“

This was its answer:

And that’s exactly what it did. It generated a Python script that I downloaded and ran locally. It provided me knobs and button parameters to adjust the method in the initial script to help ensure good output. Note that I had not explicitly requested these tuning parameters; it had determined their need itself:

I tested that script then verbosely fed back my experience to the LLM: crashes (only 2) and a few observed failures (rather falling short of tessellating expectations). We went back and forth 4 times where it adapted the algorithm until such time as I got this 5 square tessellation:

Adding circles

I wanted to add support for Circle shapes so, after uploading my current Python script, I simply instructed the LLM:

Please adapt the SDF-based packing simulator to circles in addition to squares. Use the same dynamics (mass, inertia, damping), force laws and Parameters.

And it did just that. Delivering an updated script in its entirety to allow for N_Squares and N_Circles. With Circles not affected by torque in the way Squares and their sub-divided edges had been already.

Productivity

From my first user requirement prompt it took 27 minutes for my favourite LLM to generate an SDFF script to solve the square tessellation problem. There were four back-and-forth iterations in the meantime, but it got to something acceptable really quickly.

The addition of Circles to the method took only a further 4 minutes for it to adapt.

I’m thinking now of asking it to extend the approach to accept as input a generic B&W raster image of a shape. Something that I’m sure it would accommodate directly, but I think my point is already made.

On the democratisation of ‘Makers’

In today’s industry, work is segmented into narrow competence centres and role definitions. While efficient, this segmentation can constrain how much value individuals can contribute beyond their job description.

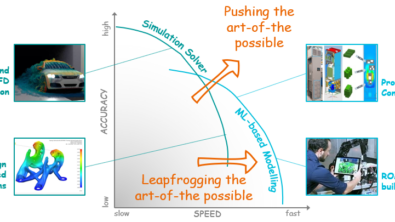

In this context, LLM assistants democratise Making. A singular role that encompasses requirements, design and delivery. Not only regarding the development of physically discrete products: https://blogs.sw.siemens.com/art-of-the-possible/engineering-simulation-part-2-productivity-personas-and-processes/#section_4 but also in the ‘production’ of Innovation concepts that might have otherwise involved numerous costly resource disciplines.

With a £20/month LLM and ~30 minutes of guided iteration, I replaced days of my time plus £1,000s of specialist effort to reach a working packing simulator. That’s the democratisation of making: moving from idea to validated prototype without gatekeepers.

Who am I?

I’m a mechanical engineer with a woefully limited mathematical vocabulary, working in a Technology Innovation group . I have loads of what I believe to be fascinating ideas that I normally think about whilst nodding off to sleep, or in the shower. I don’t have the necessary toolsets (usually mathematical and software coding), let alone the direct business justification to be able to prosecute those ideas myself in isolation.

But that’s now not true. LLMs have given me the cost effective resource and freedom to innovate concepts in a matter of hours that would otherwise have taken me days of not only my time, but many costly hours of others as well.

People will complain about 6 finger errors of multimodal LLMs, whilst they do just ignore that and exploit today’s LLMs for what they’re worth. There’s a lot to be had.

Disclaimer

This is a research exploration by the Simcenter Technology Innovation team. Our mission: to explore new technologies, to seek out new applications for simulation, and boldly demonstrate the art of the possible where no one has gone before. Therefore, this blog represents only potential product innovations and does not constitute a commitment for delivery. Questions? Contact us at Simcenter_ti.sisw@siemens.com.