Adopting a multidisciplinary design approach to achieve integrated collaboration

The aerospace and defense (A&D) industry is no stranger to complexity. Modern aircraft and spacecraft development requires the integration of numerous systems and disciplines, including mechanical, electrical, electronic and software engineering. When these teams work in silos, it leads to visibility issues, communication gaps, slower decision-making and errors that can result in costly delays.

To overcome these challenges, a multidisciplinary design and optimization (MDO) approach is crucial, allowing A&D organizations to streamline collaboration across various engineering domains, drive innovation and reduce program risks.

Are you struggling with system integration?

Traditionally, mechanical, electrical, electronic and software design teams have worked independently, often resulting in misaligned processes and objectives. A lack of integrated workflows and shared data across these domains can create significant barriers to efficiency. As noted in a recent webinar hosted by Aviation Week and sponsored by Siemens, a poll revealed that 55 percent of respondents reported difficulties in system integration as a primary challenge. This lack of integration leads to:

- Reduced visibility: Without a shared platform, teams lack insight into each other’s work, making it difficult to identify potential conflicts early in the development process.

- Communication gaps: Lack of communication among disciplines can lead to misunderstandings and missed opportunities for optimization, resulting in rework and delayed decision-making.

- Increased program risk: As programs grow in complexity, the failure to integrate disciplines increases the risk of errors, which can escalate costs and extend schedules. This was evident in the case of the Airbus A380, where electromechanical integration failures due to disjointed development systems led to a significant cost overrun of $6.1 billion.

A rendering of an integrated aircraft.

The benefits of a multidisciplinary design and optimization approach for aerospace

To address these challenges, MDO offers a comprehensive solution that integrates critical elements of product development at the earliest stages, bridging the gaps between mechanical, electrical, electronic and software design. The key benefits of this approach include:

- Improved collaboration and innovation: By fostering a collaborative environment, MDO breaks down silos and encourages teams to work together towards a unified goal. This cross-disciplinary cooperation is particularly important in areas like electrical and electronics systems, where the integration of various components can significantly impact overall performance.

- Enhanced decision-making: MDO utilizes digital tools such as digital twins and digital threads to create a cohesive design environment. These tools provide a virtual representation of the product and its processes, allowing teams to explore design space, run simulations and optimize systems in real time. For example, Siemens’ Xcelerator platform integrates electrical, mechanical and software domains, offering a seamless collaboration across product lifecycle stages.

- Reduced development time and costs: By enabling concurrent engineering and iterative processes, MDO helps reduce the time needed to bring a product to market. For instance, Wisk Aero, a company developing self-flying air taxis, reduced their electrical system design time by 50 percent using Siemens’ Xcelerator digital twin and digital thread capabilities.

- Risk mitigation: MDO helps in identifying potential issues early in the design phase to minimize the risk of costly errors. For example, Northrop Grumman uses Siemens Xcelerator to integrate program data and share product performance details seamlessly, enhancing their ability to manage design complexity and mitigate risks.

Implementing MDO in aerospace: A strategic path to digitalization

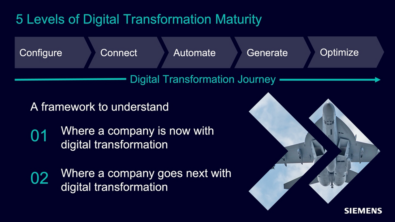

To fully leverage the potential of MDO, A&D companies must embrace digital transformation through the integration of digital threads and digital twins into their product development processes. Below are some strategic steps to consider:

Companies need to invest in digital thread capabilities. Digital threads connect data across the entire product lifecycle, ensuring that information flows seamlessly from design through production and maintenance. This connectivity allows teams to trace requirements, design decisions and changes throughout the development process, leading to more informed decision-making and better program outcomes.

Learn how to adopt digital twin technologies. The comprehensive digital twin provides a high-fidelity virtual model of both the product and the production process. They allow for the exploration of various design configurations and optimizations before committing to physical prototypes. This approach can significantly reduce development time and improve the quality of the final product. Companies like Airbus are leveraging digital twins to manage the increasing complexity of their electrical and electronic systems, ensuring first-time-right designs and smoother supply chain integration.

Focus on multidisciplinary integration. This ensures that all engineering domains are integrated into a single, cohesive workflow. The Siemens’ Xcelerator platform exemplifies this by supporting a co-design environment where electrical and mechanical engineers can collaborate effectively, reducing the need for rework and enabling faster, more accurate product development.

What’s your MDO score?

In the A&D sector, companies are often categorized into four groups based on their approach to digital transformation: struggling laggards, expensive innovators, efficient imitators and strategic leaders. We do a lot of benchmarking in the industry to understand how the companies are enabling MDO capabilities relative to competitors. Customers often fall into four distinct categories. Figure 1 illustrates the competitive space for these types of companies.

Digitalization maturity matrix for foundational digitalization capabilities in support of MDO.

By scoring companies that fall into these categories, you’ll see the following characteristics:

Struggling laggards tend to create poorly optimized designs that are hard to reuse and hard to change or update. They tend to “throw designs over the wall” to manufacturing with little regards for cost or producibility. They often use paper-based processes and find it challenging to improve their processes with technologies that are in place.

Expensive innovators do create innovative industry-leading designs, but they often use a build and break process and don’t fully invest in a digital thread strategy. Like the struggling laggards, they are prone to “throwing designs over the wall” to manufacturing with little regard for cost or producibility. Most importantly, because digital threads are not as strong, they can struggle to produce a product that meets acceptable quality levels and they cannot meet the projected rate demands.

Efficient Imitators focus on achieving good engineering processes, with or without digitalization. They do not, however, seek to create industry leading designs in part because they lack the innovative potential that comes from a high-fidelity digital twin. Due to this, they produce suboptimal designs for key A&D product types. This also means that for those key product types their overall engineering processes fail because the complexity associated with composites, electrical systems, complex assembly, aerostructures, and so on, means they inefficiently consume this product data downstream.

By contrast, the strategic leaders produce quickly defined, fully optimized designs for key A&D product types with consistent, traceable digital threads consumed into manufacturing and the larger enterprise. These industry leaders have combined the best capabilities of the Siemens Xcelerator portfolio to achieve the highest level of business performance.

To move towards strategic leadership, A&D companies must continuously invest in their digital capabilities, ensuring that their tools and processes keep pace with the evolving demands of the industry. By adopting a multidisciplinary design and optimization approach, they can not only manage the increasing complexity of modern aerospace platforms but also drive innovation, reduce costs, and meet the stringent demands of today’s market.

Achieving strategic leadership through MDO

As the aerospace and defense industry continues to evolve, the need for integrated, multidisciplinary design and optimization becomes ever more critical. By breaking down the silos that traditionally separate mechanical, electrical, and software teams, A&D companies can unlock new levels of collaboration, innovation and efficiency.

The Siemens Xcelerator platform provides an open, flexible ecosystem that serves as the foundation for achieving these goals, offering the digital tools needed to connect, optimize and accelerate product development. By embracing MDO, organizations can not only meet today’s challenges but also position themselves as leaders in the next generation of aerospace innovation.